By Chuck Kelley and Marcia Gadbois

Over the past several weeks, we have unpacked the data landscape in industrial automation, from foundational database architectures to the ETL journey that turns raw signals into usable information, and the modern practices that keep it all manageable. Each piece has built on the last, tracing how data evolves from collection to insight and, ultimately, to smarter decisions.

In this final installment, we connect the dots with a practical look at data governance. We will examine data lineage, master data management, metadata, and semantic layers, and, crucially, how these concepts apply on the plant floor and across enterprise operations. We will also highlight the role of industrial standards and regional regulatory requirements, both of which are essential as organizations scale globally and embrace Industry 4.0/5.0.

We hope you have enjoyed the series and welcome your ideas for future topics. Share your feedback with us at info@adisra.com

Contextual Data for Data Governance

In our April blog, which you can read here, we explored why clean, governed, and well-structured data is critical for industrial automation in today’s era of explosive data growth. We highlighted how governance and cleansing work hand in hand to ensure data integrity, usability, compliance, security, and performance, transforming raw information into a trusted asset that supports smarter decision-making.

Clean, governed, and well-structured data forms the foundation for reliable insights, compliance, and operational excellence in industrial automation. Yet, governance and cleansing are only part of the story. To fully unlock the value of your data, organizations also need to consider the contextual elements that give information meaning within their environment, data lineage, master data management, metadata management, and the semantic layer.

To complete the data governance process, it is important to discuss data that brings context to your organization’s environment. Those are

- Data Lineage

- Master Data Management

- Metadata Management

- Semantic Layer

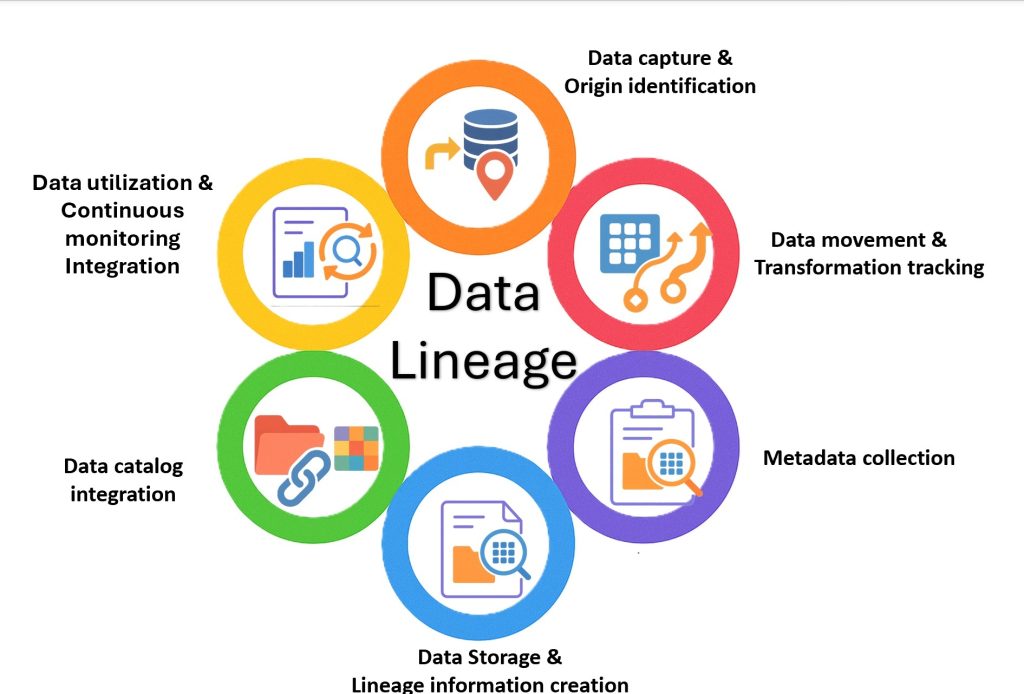

Data Lineage

When building out a data environment, you need to understand where each piece came from (collected), how it was transformed (from Fahrenheit to Celsius using what calculation), how it moved along the extraction, transformation, and load (ETL) process (was it in a stream of data or an event that occurred), and how it is used (what reports, machine learning models).

There are two main areas of data lineage:

- Technical data lineage – the aspects of moving and transforming data.

- Business data lineage – applying business context and meaning to each data element.

Usually, data lineage is seen via diagrams or maps that show the relationship between different processes and data elements.

There are several reasons why data lineage should be part of your process and to be continually pursued and updated.

- Governance – allowing the organization to understand how data flows for better management and control.

- Data Quality – identifying errors and inconsistencies in the data and where they may have been introduced.

- Compliance – ensuring the data complies with all internal and/or regulatory requirements.

- Impact Analysis – allows the organization to see how any changes to a piece of data or application will affect downstream processes and their possible use.

Master Data Management (MDM)

Master data management ensures the accuracy, consistency, and reliability of core data that drives organizational processes. Master data includes data like product specifications, material properties, and equipment details. This data reduces errors in manufacturing, inventory, and supply chain operations across the organization. Master Data should play a role in your organization for the following reasons:

- Improved operational efficiency – Automated processes require data to be correct in order to function properly. Imagine a robotic assembly line without the correct data about components and assembly. If the data were correct, it might be able to operate without human intervention. Having an MDM system allows for the sharing of data between different departments and applications, reducing the chance of data inconsistencies.

- Compliance – As you well know, industries have regulatory requirements for data accuracy and traceability. MDM helps ensure that your organization may be able to meet these requirements, reducing non-compliance and associated fines.

- Asset Management – Since MDM has information about machinery, equipment, and other assets, it can be used for maintenance scheduling, lifecycle tracking, and inventory management.

- Flexibility and Scalability – As organizations grow, so does the volume and complexity of their data. An MDM system provides the structure to seamlessly integrate new data sources and technologies into your environment. By managing data centrally and independently, MDM ensures consistency and scalability, enabling automated systems to adapt to change smoothly without disruption.

- Support for Digital Transformation – As organizations move towards digital transformation and Industry 4.0/5.0, MDM provides the foundation for integrating advanced technologies (IoT, AI, machine learning) that rely on quality master data to drive automation and insights into the manufacturing process.

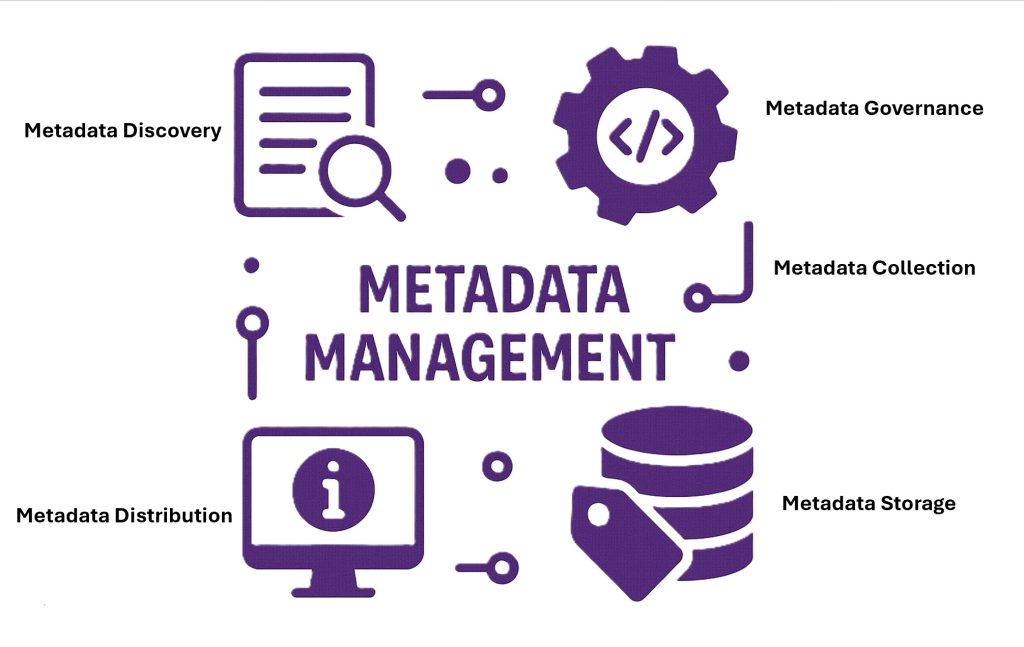

Metadata Management

Metadata is “data about data”. It refers to the information that describes, explains, and manages the data. It helps you understand the context and meaning of the data without needing to examine the data itself.

There are several types of metadata:

- Technical – The technical aspects of the data (table name, column names, datatype, ETL jobs, indexes).

- Business – The business aspects of the data (definition, business rules, restrictions of data use, context). It includes what the business calls a particular piece of data vs what technology calls it.

- Operational – Provides information on when and how the data was transformed and created. It can also provide information on when and how the data is used. Operational data can be used when an error occurs.

- Provenance – Tracks the data’s origin and any changes over time. This provides traceability so that inaccurate data can be identified and addressed. This improves data quality.

- Structural – The physical organization of data includes elements such as data names, table structures, data types, relationships, and versioning. This foundation can be used to build and maintain comprehensive data dictionaries.

- Administrative – Provides information that is used in data governance. It establishes and manages the data’s credibility. It includes data about rights and use (data security, copyright information, license agreements).

- Social – Provides useful information about data use. It includes most queried tables (frequency of use).

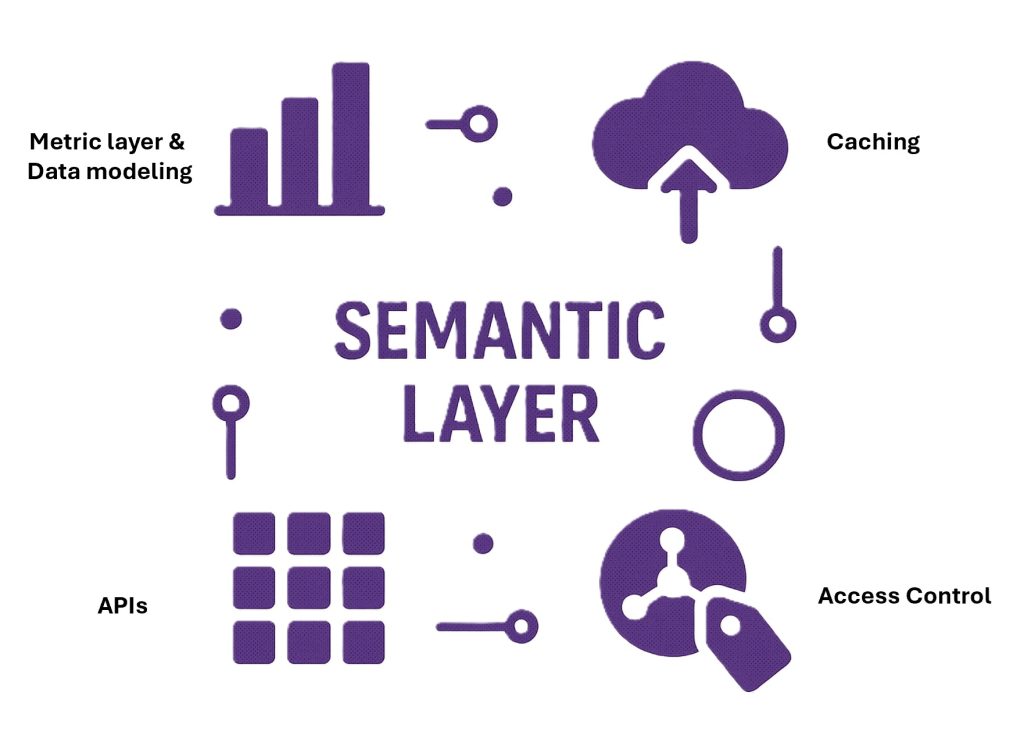

Semantic Layer

The semantic layer is an abstraction layer that sits between the user community and the underlying data. This provides a business-friendly representation of data. It translates complex data structures and technical details into meaningful business terms that are meaningful to the user community. The semantic layer enables the business community to access and analyze data without needing to understand the technical layout.

The main features of a semantic layer are:

- Unified metadata – consolidates metadata from multiple data sources to deliver a single, consistent view of the information. This unified layer includes business terms, standard calculations, and defined relationships, ensuring clarity and alignment across the organization.

- Self-service Analytics – empowers the user community to perform self-service analysis. The user community can create reports, dashboards, and ad-hoc queries without needing assistance.

- Performance Optimization – Optimizes queries and data retrieval. This reduces the load on data, which improves performance for the user community.

- Business-oriented terminology – The user community sees familiar business terms instead of technical jargon.

- Data abstraction – The semantic layer acts as a bridge between the technical data structures and the business user, hiding the complexity of the underlying systems. Because it “points” to the technical layer, the data source can change without disrupting how users access or analyze information. Queries and reports remain stable, even if the underlying database or platform is replaced. More importantly, the semantic layer defines the business view of the data, ensuring consistency across all users and applications. For example, if “Parts Rejected” is defined once in the semantic layer, every report, from quality dashboards to executive summaries, will calculate and display the metric the same way, eliminating confusion and misalignment.

- Security and governance – enforce security and access control across the data. This ensures that only authorized members of the user community have access to the data. This helps the data governance maintain a controlled environment for data access and reporting.

Data governance in industrial automation ensures the quality, security, and compliance of data generated and used in industrial environments. By establishing clear data ownership, standards, and policies; implementing robust data security measures; and promoting data awareness and training, organizations can manage their data in compliance with their objectives. Leveraging technology and tools, monitoring and reviewing data governance practices, and addressing challenges (data volume, cybersecurity threats, and regulatory compliance) are important for successful data governance initiatives.

Building on Data Governance Foundations

Effective data governance extends beyond processes and policies; it must align with recognized standards and frameworks to ensure consistency, accountability, and trust. At the same time, privacy considerations and the protection of digital assets, such as dongle files, licenses, and encryption keys, are essential for safeguarding intellectual property and maintaining operational integrity. Together, these practices strengthen resilience, minimize risk, and create a secure, compliant foundation for industrial automation.

Standards in Data Governance

Both Information Technology (IT) and Operational Technology (OT) rely heavily on data, but their governance priorities differ due to the nature of their environments.

IT Governance focuses on the management and oversight of digital assets, prioritizing confidentiality, integrity, availability, and privacy.

OT Governance centers on the safety, reliability, and performance of physical systems such as machines, control systems, and industrial equipment. Its primary goal is to prevent operational disruptions that could lead to downtime, safety hazards, or financial loss.

As IT and OT systems converge, organizations are adopting unified data governance strategies that leverage the strengths of both domains, particularly in cybersecurity, regulatory compliance, and data-driven decision-making.

IT Standards in Data Governance

Adopting established IT standards ensures consistent, auditable, and trustworthy data practices:

ISO/IEC 38505 – Guidance for governing data effectively and ethically in support of organizational goals.

ISO/IEC 27001 – Requirements for implementing and maintaining an Information Security Management System (ISMS).

NIST Privacy Framework – A voluntary framework to help organizations identify and manage privacy risks.

GDPR & CCPA Compliance – Legal frameworks that regulate the collection, processing, and protection of personal data.

Industrial Standards in Data Governance for Automation

In industrial automation, data governance must also align with standards that address both operational and regulatory needs:

ISA/IEC 62443 – Framework for securing Industrial Automation and Control Systems (IACS).

ISO/IEC 27001 – Ensures governance objectives through systematic information security practices.

ISO/IEC 38505 – Guidance on ethical and effective data use.

OPC UA – Standard for secure, reliable data exchange across industrial devices and systems.

NIST SP 800 Series (including SP 800-82) – Guidelines for securing industrial control and OT systems.

FDA 21 CFR Part 11 – Requirements for electronic records and signatures in FDA-regulated industries. Read a full blog about FDA 21 CFR Part 11 here.

GDPR-ready SCADA/HMI Frameworks – Built-in compliance features to protect personal data within control systems.

Additionally, organizations must account for regional and sector-specific regulations, including the EU’s GDPR, California’s CCPA/CPRA, Brazil’s LGPD, China’s PIPL and CSL, Canada’s PIPEDA, U.S. CFATS for chemical facilities, and national data sovereignty laws in the Middle East. Understanding the geographical requirements is critical to designing a compliant governance framework.

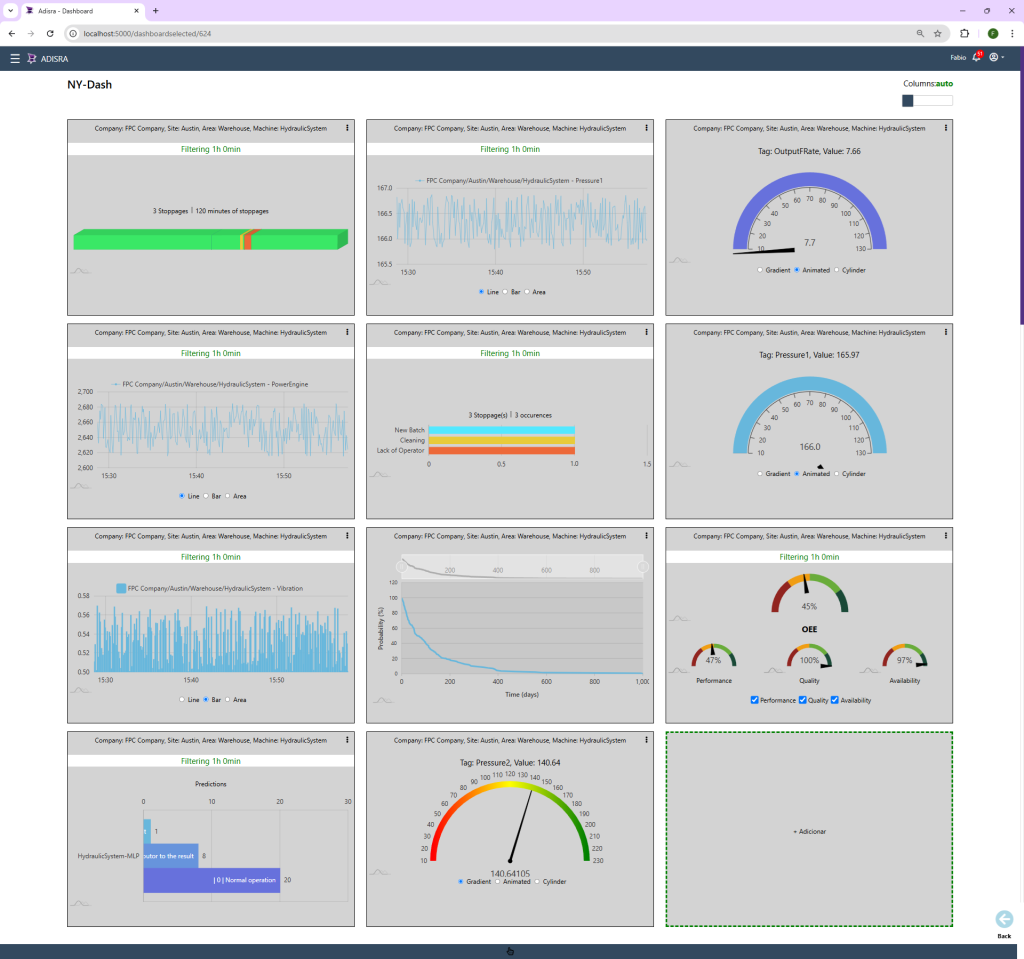

ADISRA and Data Governance

At ADISRA, we recognize that data governance and compliance are not just checkboxes; they are the backbone of modern industrial automation. Our ADISRA SmartView HMI/SCADA platform helps organizations enforce data entry standards, apply validation rules, manage role-based access, and ensure auditability in line with standards such as FDA 21 CFR Part 11. Paired with ADISRA InsightView, our analytics solution, users can transform cleansed, well-governed data into real-time KPIs, OEE metrics, and KnowledgeView with its predictive insights. Together, these solutions enable manufacturers and industrial organizations to build secure, compliant, and future-ready operations that meet both global standards and local regulations.

Get Started with ADISRA

Ready to put these best practices into action? Start building intelligent industrial automation solutions today with ADISRA SmartView. Download your trial here.

Have a project in mind? Request a personalized demonstration with our team and see how we can support your goals.

Interested in exploring analytics and predictive maintenance? Request a temporary account for InsightView and KnowledgeView at info@adisra.com. If you already have an account, you can access both platforms here.

Conclusion

As industrial automation grows more data-driven, aligning governance practices with established standards has shifted from optional to essential. By uniting IT and OT governance principles, embracing both global and regional frameworks, and safeguarding critical digital assets, organizations can create a secure, compliant, and resilient foundation, one that not only supports operations today but also drives long-term digital transformation.

ADISRA®, ADISRA’s logo, InsightView®, and KnowledgeView® are registered trademarks of ADISRA, LLC.

© 2025 ADISRA, LLC. All Rights Reserved.

Chuck Kelley is a consultant, computer architect, and internationally recognized expert in data technology. With over 40 years of experience, he has played a key role in designing and implementing operational systems, data stores, data warehouses, and data lakes. Chuck is the co-author of Rdb/VMS: Developing the Data Warehouse with Bill Inmon and has contributed to four books on data warehousing. His insights have been featured in numerous industry publications, where he shares his expertise on data architecture and enterprise data strategies. Chuck’s passion lies in ensuring that the right data is delivered in the right format to the right person at the right time.