Manufacturers and industrial operations are facing a frightening crossroads regarding automation obsolescence. Their once-mighty systems are aging, and like haunted machinery lurking in the shadows, they must decide the best path forward. Many face the chilling dilemma of how to handle their ancient control systems, those relics that have become obsolete due to disappearing support, rising maintenance costs, and their inability to mingle with modern technologies like Ethernet-based networks or plant asset management applications.

The nightmare deepens when critical spare parts vanish into the abyss, are discontinued, or are simply impossible to find. But don’t scream just yet! “Obsolete” does not always mean “unattainable.” As we have mentioned in previous blogs, some of our brave ADISRA customers have scoured the dark corners of eBay, resurrecting their machines with long-lost parts.

In the spirit of Halloween, we thought it would be fun (and maybe a little spooky) to shine a flashlight on some of the equipment and operating systems that still haunt our industry today, those skeletons in our industrial closet that refuse to rest in peace.

Graveyard of Operating Systems: When Windows 10 Joined Its Undead Family

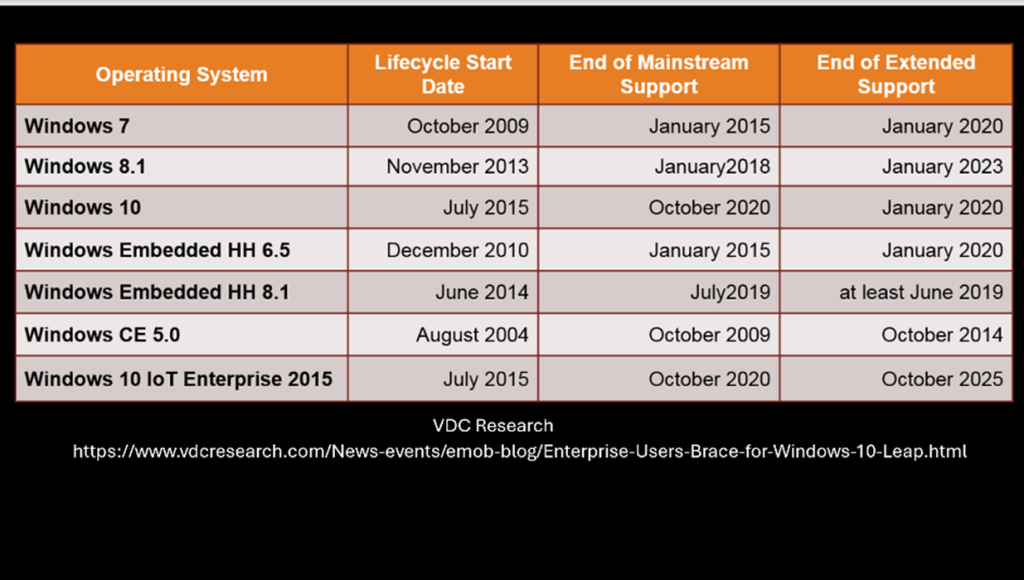

On October 14, 2025, Microsoft officially laid Windows 10 to rest, joining its ghostly predecessors, Windows 7 and Windows CE, in the ever-growing graveyard of operating systems. According to Food Engineering’s June 9, 2025, article, “Ready? Windows 10 Support Ends in 2025, but Industrial and Enterprise Users Have Options.” Microsoft estimated that as of March, Windows 10 still held a 54% market share, while Windows 11 had risen to 43%.

To ease the transition, Microsoft announced that those needing a little more time before moving to a new Copilot+ PC or Windows 11 device could take advantage of its Extended Security Updates (ESU) program, which provides one final year of protection for Windows 10 systems beyond October 14, 2025. ADISRA published an extensive blog covering the official end of support for Windows 10, which can be viewed here.

At ADISRA, we understand that many industrial and enterprise users dread major operating system upgrades as much as a haunted house, often due to concerns about hardware compatibility, software validation challenges, and the risk of disrupting critical operations. For that reason, ADISRA SmartView will continue to operate on Windows 10 for the foreseeable future, though, like a spirit tethered to its old home, feature enhancements, security updates, and bug fixes tied to the operating system can no longer evolve. We encourage our customers to begin their migration toward Windows 11 wherever possible, before obsolescence becomes a full-blown fright.

The ghost story does not end there. Windows Embedded CE, whose mainstream support vanished back in April 2018 and whose extended support faded away in October 2023, still roams the industrial realm. Some OEMs can continue purchasing licenses until 2028—a brief reprieve before the final curtain falls. This limited window allows businesses to either maintain their legacy systems a bit longer or prepare for reincarnation through newer platforms.

ADISRA SmartView does not run on Windows CE, but it thrives on modern and robust environments such as Windows IoT and Linux, offering flexible options for those ready to bring their systems back from the brink of obsolescence. ADISRA still encounters loyal users of Windows CE, particularly in embedded systems that seem to live forever. Many are evaluating their next move:

– Migrating to Windows IoT

– Switching to Linux

– Continuing to rely on their aging Windows CE environments—hoping the lights don’t flicker out too soon.

But just as with operating systems, the creeping hand of obsolescence reaches further into the factory floor. Many Programmable Logic Controllers (PLCs) are beginning to show their age, too—controllers that once powered production now act as silent sentinels from another era. These aging PLCs, much like Windows CE and Windows 10 systems, can quickly transform from trusted tools to technological tombstones if not given a plan for modernization.

Skeletons in the Control Cabinet: The Haunting of Obsolete Programmable Logic Controls (PLCs)

Deep within the factory’s dimly lit control cabinets lie the skeletons of automation past, PLCs that once pulsed with energy but now whisper through aging circuitry like restless spirits.

The SIMATIC S7-300/ET 200M system families, long-standing members of Siemens’ automation lineage, have faithfully served manufacturers worldwide. Yet even the strongest spirits must eventually fade. Siemens has officially sounded the death knell for these product lines this month. Spare parts will remain available for a decade, until 2033, but their days of active service are now numbered, haunting legacy systems that refuse to move on.

For nearly forty years, the Allen-Bradley® PLC-5 and its loyal companion, RSLogix 5, stood as cornerstones of industrial automation, reliable, steadfast, and seemingly immortal. But time is a relentless reaper. RSLogix 5 will enter its final life cycle phase on December 31, 2025, marking the end of an era. As the last remaining software capable of communicating with the PLC-5 (discontinued in 2017), it now lingers like a ghost in the system. Rockwell Automation has urged users to migrate toward Studio 5000 Logix Designer and the modern Logix family of controllers, leaving the PLC-5 to rest in well-earned peace.

Even Mitsubishi Electric’s Alpha2 Series Controllers, once celebrated for their simplicity and reliability, are preparing for their final act. Production ceased on September 30, 2025, with the last orders accepted on May 30, 2025. Mitsubishi encourages users to move toward the MELSEC iQ-F and MELSEC-F series, offering fresh lifeblood to replace their soon-to-be spectral predecessors.

Across the automation world, these controllers linger like industrial apparitions, still running production lines, still blinking faintly in control rooms, but each day growing closer to joining the great graveyard of legacy hardware.

From Haunted Cabinets to Fading Screens

The ghosts of automation do not stop at the control cabinets. Beyond the racks and wiring, Human-Machine Interface (HMI) panels tell a story just as chilling. Once bright portals into the heart of industrial control, these panels now flicker like candlelight in an abandoned factory, their screens dimming as time drains their vitality. Some still cling to life on outdated operating systems; others rely on aging components that creak like old floorboards in the night. All share the same haunting question: How long before the ghosts of obsolescence come tapping at their glass?

The classic Siemens SIMATIC HMI Comfort Panels are the latest to join the procession into the shadows. The phase-out began on October 1, 2024, with the 15″–22″ models leading the descent. These panels are no longer actively marketed, and the transition to replacement parts and service has begun. Their successor, the SIMATIC Unified Comfort Panel, emerges from the fog as a worthy heir, boasting higher performance, improved security, and a Linux-based operating system that breathes new life into the operator interface.

Meanwhile, the Allen-Bradley PanelView Standard HMIs have long since crossed to the other side. Their end of life came well before 2025, and while spare parts may still wander the secondary market like relics of the past, the line is now a legacy phantom, replaced by the PanelView Plus and PanelView 5500 series, modern embodiments ready to face today’s industrial challenges.

And then there’s Parker Hannifin, preparing to lay its entire HMI line to rest. Struggling under the weight of fading sales and material shortages, Parker has announced its final time-buy period ending July 30, 2025, with final shipments due by December 30, 2025. After that, only in-warranty units will receive support. Out-of-warranty devices? They’ll be left behind, no service, no parts, only echoes of their once-reliable touchscreens.

Across the factory floor, these fading HMIs stand like electronic tombstones—reminders of how quickly technology evolves and how swiftly yesterday’s innovations can become today’s legends.

Conclusion: Escaping the Haunted Factory Floor

According to research from ARC and Schneider Electric, nearly $65 billion worth of industrial automation assets are teetering on the edge of obsolescence, an eerie number that represents real ghosts haunting factory floors worldwide. These aging systems, though once dependable workhorses, now creak under the weight of time. Many manufacturers still rely on them, unaware of the hidden horrors, rising maintenance costs, creeping security vulnerabilities, and the lurking threat of downtime waiting in the dark.

Keeping legacy systems alive can feel like maintaining a restless spirit. Each day demands new patches, workarounds, and costly repairs just to keep the machinery from fading into silence. The longer these systems linger, the more they drain precious resources and energy, becoming barriers to innovation and anchors to the past.

But there is no need to fear the future. Modernization does not have to be a nightmare. ADISRA understands how frightening it can be to transition to new technology while production must continue. That is why our software is designed to make migrations as smooth as possible, turning what once seemed like a haunting transformation into a seamless rebirth.

And if things ever go bump in the night, our team is always close by. Whether through online chat, email, or telephone, ADISRA is ready to exorcise any issue that arises and keep your automation running safely and efficiently.

Ready to bring your operations back from the dead?

Download ADISRA SmartView and experience the next generation of industrial automation.

Or, if you would prefer a guided tour through the land of the living, click here to request a demo. Our team of experts is always here to help you escape the ghosts of legacy systems.

ADISRA®, ADISRA’S logo, InsightView®, and KnowledgeView® are registered trademarks of ADISRA, LLC.

© 2025 ADISRA, LLC. All Rights Reserved.

Microsoft CE, Microsoft Embedded CE, Windows 7, Windows 10, Windows 11, Windows IoT, CoPilot + PC are registered trademarks of the Microsoft group of companies.

Linux is the registered trademark of Linus Torvalds.

SIMATIC S7-300/ET200M, SIMATIC HMI Comfort Panels, and SIMATIC Unified Comfort Panel are the registered trademarks of Siemens AG.

Allen Bradley PLC5, RS Logix 5, PanelView, PanelView Plus, and PanelView 5500 Series are the registered trademarks of Rockwell Automation and its subsidiary entities.

Rockwell Automation Studio 5000 Logix Designer is the registered trademark of Rockwell Automation and its subsidiary entities.

Mitsubishi Electric Alpha 2 Series Controllers, MELSEC iQ-F and MELSEC-F Series are the registered trademarks of Mitsubishi Electric Corporation.

Parker and Parker Hannifin are the registered trademarks of Parker Hannifin Corporation.

Excellent article! I like how it brings the Halloween story to the factory floor, highlighting a problem for industries in general.

It’s true that planned obsolescence is a major challenge, not only in hardware and software automation, but also in our daily lives.