Analytics have become the engine behind smarter automation, predictive insights, and continuous optimization as smart sensors, IIoT devices, and AI/ML continue to redefine the industrial landscape. From mixing and blending to packaging and distribution, industrial analytics enables food processors to see more, understand faster, and act smarter.

Industrial analytics refers to the technologies and processes used to collect, integrate, and analyze time-series data, information captured at regular intervals that reflects changes in equipment performance, process variables, and system behavior. By harnessing this steady stream of operational data, food manufacturers can identify trends, detect anomalies, and make data-driven decisions that boost efficiency, reliability, and product quality.

At its core, industrial analytics transforms raw operational data into actionable intelligence. Integrated within modern automation systems, it combines advanced software tools, statistical modeling, and machine learning techniques to enable seamless data collection, visualization, and analysis.

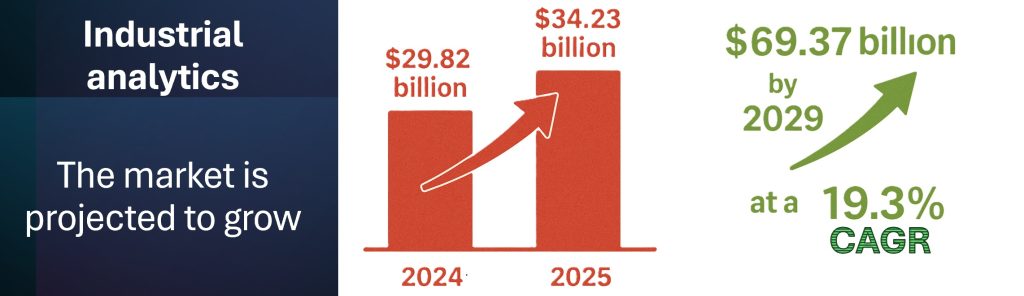

The momentum behind this technology is undeniable. The industrial analytics market is projected to grow from $29.82 billion in 2024 to $34.23 billion in 2025, driven by the need for efficiency, predictive maintenance, cost reduction, supply chain optimization, and regulatory compliance.

Looking ahead, the industrial analytics market is expected to grow even faster, reaching $69.37 billion by 2029 at a CAGR of 19.3%. The next phase of expansion will be fueled by a heightened focus on cybersecurity, edge computing integration, and industry-specific, customized analytics solutions. Key trends shaping this growth include advanced sensor integration, digital twin implementation, and cybersecurity for industrial systems.

In short, industrial analytics is not just a tool; it is the foundation for a new era of intelligent, connected, and continuously improving food manufacturing operations.

The Four Types of Industrial Data Analytics

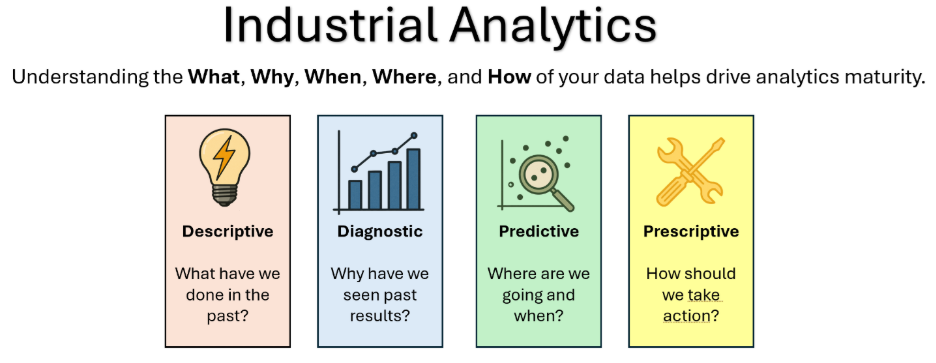

Data analytics is the driving force that transforms raw data into actionable intelligence in industrial automation. It enables organizations to move from simply understanding what happened to proactively deciding what should happen next. This journey progresses through four primary types of analytics, from descriptive insights that explain past events to prescriptive insights that recommend optimal actions for the future.

Descriptive Analytics – Understanding What Happened

Descriptive analytics serves as the foundation of data analysis, focusing on summarizing and interpreting historical and real-time data to answer the question, “What happened?” It organizes vast amounts of raw information into clear, meaningful insights, offering a comprehensive view of past performance and operational trends. By turning data into an understandable narrative, descriptive analytics helps organizations identify patterns and measure results — forming the baseline for smarter, forward-looking decisions.

Diagnostic Analytics – Discovering Why It Happened

Diagnostic analytics goes beyond simply reporting what occurred; it digs into historical data to uncover the why behind specific outcomes, trends, or anomalies. By identifying root causes and contributing factors, it provides valuable context and a deeper understanding of performance issues. This stage of analytics transforms data into actionable insights, helping organizations pinpoint inefficiencies, resolve issues, and make more informed operational decisions.

Predictive Analytics – Anticipating What Could Happen

Predictive analytics is an advanced form of data analysis that leverages historical and real-time data, combined with statistical modeling, machine learning, and data mining, to forecast future events and behaviors. It moves beyond understanding what happened or why it happened to provide a data-driven view of what is likely to occur next, enabling organizations to anticipate trends, prevent issues, and make proactive, strategic decisions.

Prescriptive Analytics – Recommending What to Do Next

Prescriptive analytics goes beyond understanding past events and predicting future ones by leveraging data to recommend specific actions or decisions to optimize outcomes. Its core function is answering the question, “What should we do next?”

In short, descriptive and diagnostic analytics help understand the past, while predictive and prescriptive analytics empower food manufacturers to shape the future, creating a foundation for intelligent, data-driven automation.

Applications of Industrial Data Analytics in Food Processing

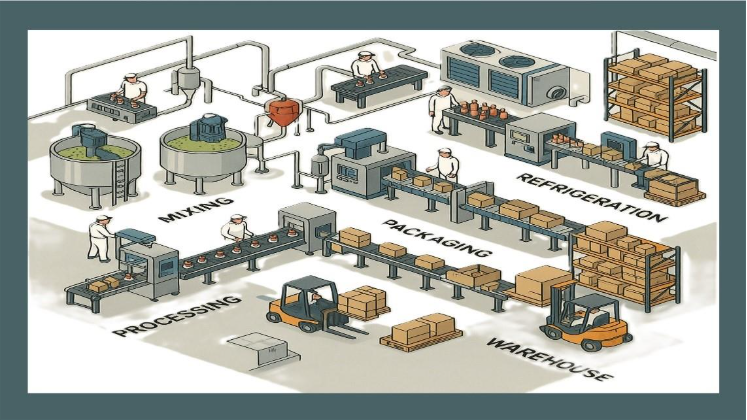

Imagine a modern food processing plant producing bottled beverages. Every mixer, pasteurizer, and filler generates continuous data, including temperature and pressure readings, fill-level consistency, and energy usage. When this data is analyzed in real time, plant managers gain complete visibility into their operations, empowering them to make smarter, faster, and more confident decisions.

With today’s automation tools, industrial analytics becomes the foundation for operational excellence. Here is how it transforms every stage of food production:

– Data-driven insights: Analytics replaces guesswork, optimizing production recipes, resource allocation, and process parameters.

– Identifying bottlenecks: Detects inefficiencies, such as a filling machine lagging behind throughput targets, allowing adjustments to maintain flow.

– Improved safety: Analyzes sanitation and temperature data to ensure compliance with food safety regulations like the Food and Drug Administration (FDA) and Hazard Analysis and Critical Control Points (HACCP). For more details on how ADISRA SmartView supports FDA 21 CFR Part 11 compliance, please refer to our previous blog post.

– Improved scheduling: Uses production insights to align maintenance and cleaning cycles with downtime windows.

– Innovation: Supports continuous improvement and process development for new product formulations.

– Optimized inventory management: Synchronizes ingredient supply with production schedules, reducing waste and storage costs.

– Optimized resource allocation: Balances labor and energy usage across lines for maximum efficiency.

– Predictive maintenance: Identifies early signs of equipment wear in pumps, conveyors, or compressors to prevent costly shutdowns.

– Real-time quality control: Monitors fill weights, temperatures, and pH levels to maintain consistent quality and reduce rework.

– Reduced downtime: Predictive insights and automatic alerts minimize unplanned stoppages, improving throughput and OEE.

The benefits ripple across the organization, greater efficiency reduces energy waste, higher consistency enhances product quality, and improved visibility strengthens safety and reliability.

Industrial Analytics in Action: The Smart Food Processing Plant

In a modern food processing facility, data analytics touches every stage, from raw ingredient intake to final packaging. Each process generates valuable information that can be used to monitor performance, detect inefficiencies, and maintain compliance.

At the center of this transformation are the HMI (Human-Machine Interface) and SCADA (Supervisory Control and Data Acquisition). These systems come in many form factors, from standalone screens on the production floor to cloud-based dashboards and mobile devices, but their mission is the same: to visualize operations and control equipment.

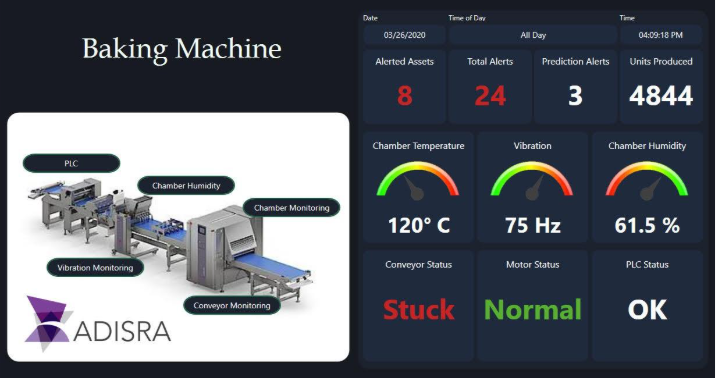

ADISRA SmartView: The Heart of Intelligent Visualization

ADISRA SmartView is a powerful, intuitive, and affordable HMI/SCADA software built for industrial analytics in today’s connected plants. Whether deployed on IIoT devices, embedded panels, industrial PCs, or in the cloud, ADISRA SmartView collects data from multiple sources and transforms it into clear, actionable visualizations.

ADISRA SmartView’s rapid application development environment enables food processors to quickly create real-time dashboards for monitoring production rates, temperature trends, batch data, and quality parameters. The platform supports template reusability, on-demand tag creation, and quick prototyping, making it ideal for agile development and continuous improvement.

Unique features such as 2D/3D array visualization, support for complex data types, and an intuitive engineering interface accelerate learning and deployment.

With broad interoperability, ADISRA SmartView connects effortlessly to PLCs, databases, and other third-party packages. With a variety of both OT and IT protocols, including Modbus TCP, Siemens, Mitsubishi, OPC UA, MQTT, HTTP/HTTPS, and database integration.

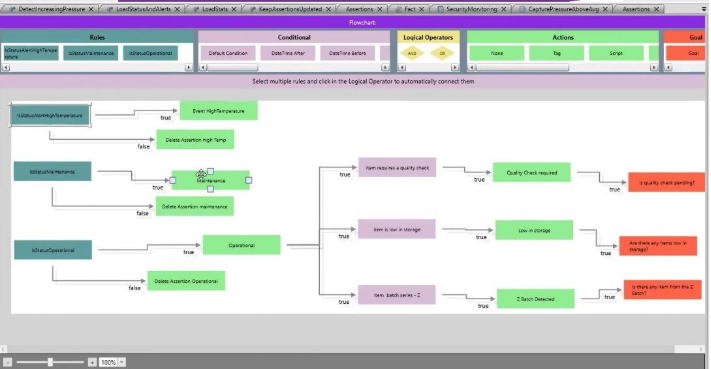

Rule-Based Intelligence for Smarter Automation

Equipped with an integrated rule-based expert system, ADISRA SmartView moves beyond visualization into intelligent automation. In a food processing plant, for instance, it can monitor a pasteurizer or packaging line and apply expert rules to live sensor data to enhance performance, reliability, and safety in real time.

Example Rule (Pasteurizer):

IF temperature drops below 72°C for more than 30 seconds, THEN alert the operator and initiate a safety hold to ensure product integrity.

Example Rule (Packaging Line):

IF fill level deviation exceeds 3% for five consecutive bottles, THEN trigger a quality alert and auto-adjust filler valve timing.

By applying rules like these in real time, ADISRA SmartView delivers:

– Instant alarms when process parameters drift outside acceptable limits.

– Automated corrective actions to prevent quality or safety issues.

– Early warnings to schedule maintenance before costly downtime.

This rule-based expert system bridges analytics and automation, turning data insights into immediate operational improvements and ensuring every product meets strict quality and safety standards.

Experience it for yourself: Download a trial of ADISRA SmartView

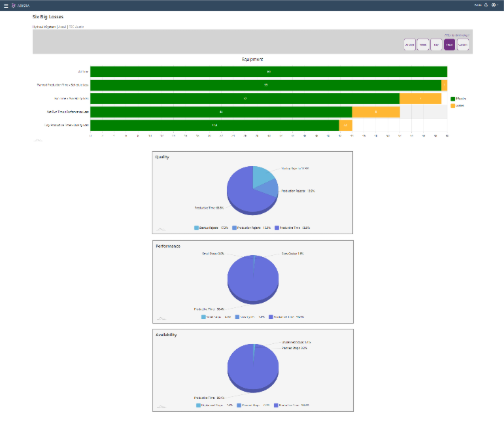

ADISRA InsightView: Turning OEE into Continuous Improvement

While SmartView powers real-time visualization on the plant floor, ADISRA InsightView extends analytics to the enterprise level. This cloud-based OEE and analytics platform provides a unified view of equipment performance, availability, and quality across all production lines and facilities.

In a food processing operation, InsightView helps plant managers identify bottlenecks, compare shift performance, and monitor OEE across sites to standardize best practices.

Built on AWS or Azure, InsightView transforms raw production data into actionable insights and allows users to drill down into the Six Major Losses affecting OEE, including equipment failures, setup losses, idling, speed losses, defects, and startup losses.

Key metrics include:

– Opportunity Gap – Difference between potential and actual output.

– Capacity Utilization – How effectively each line uses its available capacity.

– Cycle Time and Efficiency – Measuring process rates and value-added time.

– Throughput – Quantifying how much product each line produces over time.

– Planned Maintenance Percentage – Balancing scheduled versus emergency maintenance.

With these insights, food manufacturers can improve productivity, reduce waste, and optimize asset utilization, ensuring consistent performance across every facility.

Want to experience InsightView for yourself? Request an account at info@adisra.com.

Want a private webinar on any of these products? Request the webinar here.

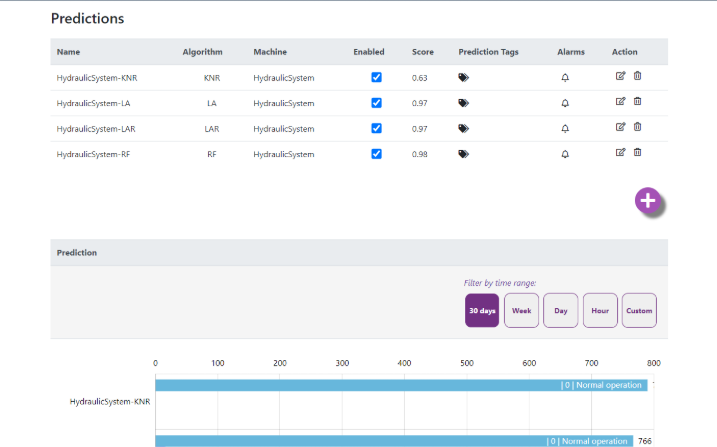

ADISRA KnowledgeView: Predictive and Prescriptive Intelligence for Food Manufacturing

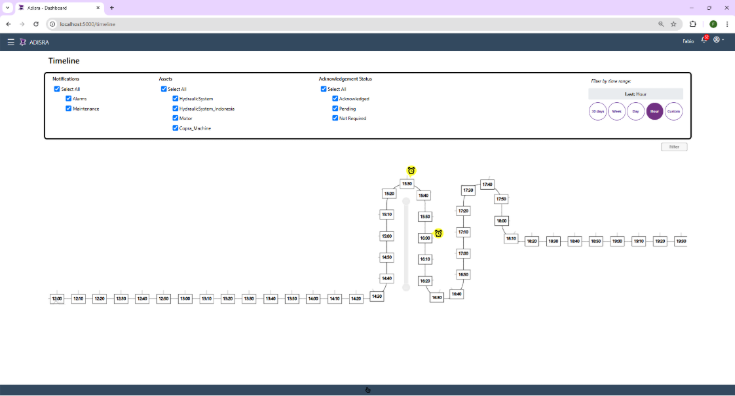

The next evolution in industrial analytics is not just predicting what might happen; it is knowing what to do next. ADISRA KnowledgeView combines predictive and prescriptive analytics to transform how food processors manage equipment health, production performance, and maintenance planning.

In a food plant, KnowledgeView continuously analyzes data from mixers, pumps, chillers, and conveyors to detect subtle patterns that indicate early signs of wear or process drift. Using machine learning, time-series analysis, and anomaly detection, it identifies issues before they cause downtime or quality loss.

But KnowledgeView also delivers prescriptive analytics that recommend the best corrective action, such as adjusting process parameters, replacing worn components, or modifying maintenance schedules.

Example Scenario:

– Predictive Insight: A chiller compressor shows a rising vibration pattern and reduced cooling efficiency.

– Prescriptive Action: Recommend bearing inspection and partial load operation until service is completed.

By combining predictive foresight with prescriptive recommendations, KnowledgeView helps increase asset life, maintain consistent quality, and minimize maintenance costs, keeping every process line running at peak performance.

Built on scalable cloud architecture, KnowledgeView integrates seamlessly with ADISRA SmartView and InsightView, creating a unified analytics ecosystem from the plant floor to the enterprise cloud.

Interested in trying KnowledgeView? Request a temporary account at info@adisra.com.

The Complete ADISRA Analytics Ecosystem

Together, ADISRA SmartView, InsightView, and KnowledgeView form a powerful industrial analytics ecosystem that transforms how food processors monitor, analyze, and optimize operations.

From real-time visualization to OEE-driven performance analytics and AI-based predictive and prescriptive maintenance, ADISRA delivers a unified, data-driven approach to maximize uptime, efficiency, and profitability, all while maintaining safety, compliance, and product quality.

In the age of Industrial Analytics, ADISRA empowers the food processing plant of the future to see smarter, act faster, and operate better.

Start building intelligent industrial automation solutions today with ADISRA SmartView —download it here.

Have a project in mind? Let us talk. Click this link to request a personalized demonstration with our team.

Need a temporary account for InsightView, and KnowledgeView. Request the account at info@adisra.com

If you have a temporary account, you can access InsightView and KnowledgeView here.