After reading a recent LinkedIn post by ADISRA’s partners in Singapore and Malaysia, EDEX TECHNOLOGY SDN BHD (Malaysia) and EDEX TECHNOLOGY PTE LTD (Singapore), one point stood out clearly: OEE through the “rearview mirror” helps us understand what has happened. Still, it is far less valuable unless we also uncover why it happened. Actual improvement does not come from simply measuring productivity; it comes from understanding the root causes behind performance gaps and using data-driven insights to drive continuous improvement.

That perspective sparked a deeper question for us: What happens when AI enters the OEE conversation? How can AI move OEE beyond retrospective reporting and transform it into real-time intelligence and proactive optimization?

Before exploring this trend, it is important to reiterate why OEE remains such a foundational metric in manufacturing. Overall Equipment Effectiveness has long been the standard for evaluating how well a process is running across Availability, Performance, and Quality. When measured consistently, OEE offers powerful benefits: it exposes production bottlenecks, increases throughput, reduces waste, and ultimately drives more efficient operations. It can even reveal hidden capacity in existing equipment, helping manufacturers boost output in weeks or months without costly upgrades or replacements.

OEE also brings critical transparency to the plant floor. Operators gain real-time insight to quickly address losses and prevent them from escalating, while managers can rely on trusted data to make more intelligent, faster decisions. But as EDEX rightly pointed out, actual improvement only happens when teams look past the numbers and start by identifying the root causes behind performance losses. This is where understanding the Six Major Losses becomes essential.

Those insights inspired this blog. Today, we explore how AI and OEE together will reshape the future of industrial operations, and why the next few years will be a defining moment for organizations that rely on OEE as a key measure of productivity.

Turning Historical Data into Action

Analyzing historical production data is far easier today than ever before, but many planned and unplanned factors can still influence efficiency. This is especially true in semi-automatic assembly lines, where human work naturally varies, assembly times and cycle times differ from person to person, and even from shift to shift. Machine faults add another layer of unpredictability, occurring at random intervals and lasting for uncertain durations.

When used effectively, however, this wealth of data can create powerful competitive advantages. It can drive improvements in productivity, quality, and efficiency, all critical KPIs in today’s highly competitive manufacturing landscape. As companies shift toward low-volume, highly personalized production, their success depends not only on equipment and resource availability but also on the optimized execution of every production process.

This shift creates a significant opportunity: by feeding these new streams of data into modern analytics, manufacturers can build more innovative models, tools, and decision-support systems. They can then benchmark these insights against traditional methods to validate improvements.

That is where Overall Equipment Effectiveness (OEE) shines. Designed to measure the key sources of production loss, OEE serves as a powerful benchmarking KPI for identifying and prioritizing areas for process improvement.

How AI Elevates Manufacturing Beyond Traditional Methods

Artificial intelligence (AI) refers to a set of technologies that enable machines, especially computer systems, to perform tasks that typically require human intelligence. Within AI, machine learning (ML) focuses on helping systems improve automatically by learning from data and past experiences.

In industrial environments, AI comes with unique expectations. It is not just about predicting or forecasting outcomes; it is also about deepening process knowledge and selecting the right algorithms to gain an advantage that traditional methods can’t provide. AI delivers powerful capabilities such as automatic quality prediction, full part traceability, process optimization, and predictive maintenance, all of which directly impact productivity KPIs like OEE and machine downtime.

Here are a few simple examples of how AI is transforming manufacturing processes:

- Faster Setup: AI can analyze past production runs to reduce setup and changeover time when new work orders arrive. Faster, more accurate setups increase equipment availability, which directly boosts OEE.

- Reducing Process Deviations: By predicting quality issues based on real-time process parameters and automatically adjusting those parameters, AI helps improve product quality and reduce scrap, another major driver of higher OEE.

- Smarter Maintenance: AI-powered predictive maintenance identifies when equipment is likely to fail and allows teams to schedule repairs and order spare parts in advance. This reduces unplanned downtime, increases availability, and further improves OEE.

Together, these capabilities show how AI is becoming a crucial tool for modern manufacturing, strengthening productivity, reducing waste, and enabling continuous improvement across the entire operation.

How ADISRA’s Industrial Ecosystem Elevates OEE, Today and Into the AI-Driven Future

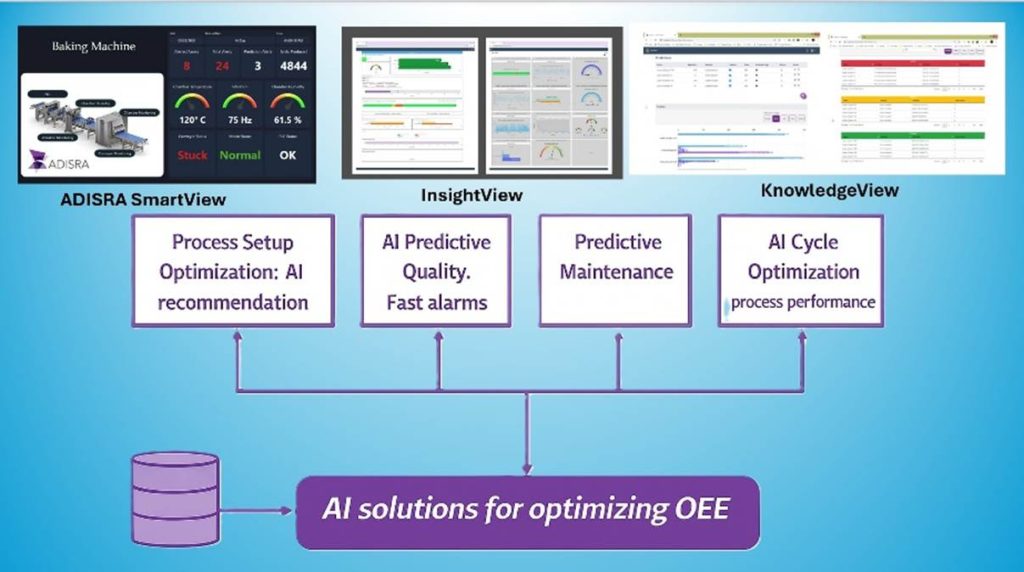

As manufacturers seek ways to turn real-time data into action, ADISRA SmartView provides a robust foundation for maximizing Overall Equipment Effectiveness (OEE). Its intuitive HMI interface gives operators immediate insight into availability, performance, and quality right from the plant floor. By seamlessly connecting with a wide range of equipment and systems, ADISRA SmartView provides a unified view of production health, helping teams quickly identify bottlenecks, inefficiencies, and opportunities for improvement. With this visibility, operators and managers can make faster, smarter, data-driven decisions that increase productivity and minimize downtime.

A key differentiator of ADISRA SmartView is its built-in rule-based expert system. This intelligent engine can automatically detect events such as slow cycle times, quality deviations, or early signs of downtime, and respond instantly. Whether triggering alerts, adjusting parameters, or initiating corrective actions, ADISRA SmartView helps prevent minor issues from becoming major disruptions. This proactive, automated approach strengthens continuous improvement initiatives and keeps equipment running at peak efficiency.

Complementing ADISRA SmartView, InsightView extends analytics across machines, lines, and entire facilities. Its cloud-based dashboards offer clear visibility into OEE, the Six Big Losses, and other essential metrics, making it ideal for mid-market manufacturers that need advanced analysis without heavy IT overhead. Delivered as a SaaS solution, InsightView provides rapid time-to-value, flexible customization, and ongoing updates that ensure users always have access to the latest features.

With OEE offering deep insight into the causes of equipment losses, maintenance teams can better plan repairs and interventions. KnowledgeView further enhances this by using predictive and prescriptive analytics to forecast failures, optimize maintenance timing, and guide teams toward the most effective actions. This reduces unplanned downtime, improves availability, and strengthens overall production performance.

Together, ADISRA SmartView, InsightView, and KnowledgeView form a synergistic industrial analytics ecosystem. When enhanced with the built-in AI, this trio has the potential to take OEE to an entirely new level. Real-time visualization, OEE-driven performance analytics, predictive and prescriptive maintenance, and automated decision support all come together to help manufacturers maximize uptime, efficiency, and profitability, while maintaining safety, compliance, and product quality.

In the age of Industrial Analytics, ADISRA empowers manufacturers to see smarter, act faster, and operate better, turning data into a strategic asset for continuous improvement.

Start building intelligent industrial automation solutions today with ADISRA SmartView. Download it here.

Interested in InsightView or KnowledgeView? Request a temporary account at info@adisra.com.

Have a project in mind? Let’s talk. Click here to schedule a personalized demonstration.

Conclusion

Integrating AI into production processes is the next significant step in maximizing Overall Equipment Effectiveness and elevating productivity across the manufacturing landscape. It is an investment that not only improves OEE but also strengthens a company’s competitive position. In an environment where efficiency and rapid adaptation are essential, AI enables manufacturers to build resilient, future-ready operations. With AI, OEE evolves from a static measurement into a dynamic tool, one that continuously learns, adapts, and guides smarter decisions every day.

As manufacturers move toward an increasingly data-driven future, those who embrace AI-enhanced OEE will be better positioned to reduce downtime, uncover hidden capacity, and accelerate continuous improvement. The companies that invest today will define the performance benchmarks of tomorrow.

Upcoming Event

Webinar Invitation: “From the Shop Floor to the Cloud: Maximizing OEE Everywhere” on 9 December 2025 – 9:30 a.m. CST; 10:30 a.m. CCOT; 3:30p.m. UTC/GMGMT; 4:30.m. CET; 5:30 p.m. EET; 11:30 a.m. (10 Dec) MYT;

Register for the webinar here.

Manufacturers today face a critical challenge: achieving complete visibility into production efficiency, whether at the machine level, within a single facility, or across an entire network of dairy plants.

Join us for our upcoming webinar, “From the Shop Floor to the Cloud: Maximizing OEE Everywhere,” where we explore how to optimize OEE both on-premise and in the cloud.

This session will demonstrate how ADISRA SmartView delivers real-time OEE precision at the machine and plant level, while ADISRA InsightView provides multi-site visibility, benchmarking, and cloud-driven analytics for strategic, enterprise-wide decision-making.

Whether you manage one facility or multiple plants across regions, you will learn how to:

- Measure and improve performance in real time at the machine, line, and plant level

- Aggregate OEE data across multiple sites for deeper insights and cross-plant benchmarking

- Empower teams at every level with unified visibility, alerts, and collaboration tools

- Accelerate improvement cycles using cloud analytics, dashboards, and predictive insights

Do not miss this opportunity to discover how modern OEE solutions bridge the gap between operations and strategy, helping you increase efficiency, reduce downtime, enhance quality, and stay competitive in a connected manufacturing world.

Register now for this webinar here.