Industrial automation has reached an inflection point. What were once standalone SCADA and HMI systems have evolved into intelligent, connected platforms that now sit at the center of modern operations. Today, these systems are no longer just visualizing data; they enable faster decisions, deeper insight, and more resilient production environments.

At the core of this transformation is the ability to capture, analyze, and act on operational data in real time. Modern SCADA and HMI platforms provide continuous visibility into processes, assets, and resource flows, turning raw signals into actionable intelligence. Operators can instantly detect deviations, engineers can diagnose issues as they emerge, and management teams can track performance against key operational metrics with confidence.

This shift from reactive monitoring to proactive, data-driven decision-making is redefining how manufacturers operate. Downtime is reduced, throughput is optimized, and organizations gain the agility needed to compete in an increasingly dynamic industrial landscape.

The latest release of ADISRA SmartView builds directly on this momentum, introducing new capabilities that enhance usability, connectivity, performance, and deployment flexibility, while reinforcing ADISRA SmartView’s role as a modern foundation for intelligent industrial applications.

Connectivity Enhancements That Strengthen the Industrial Data Backbone

In 2026, connectivity within HMI/SCADA platforms is no longer a supporting feature; it is the foundation for operational intelligence, system scalability, and Industrial IoT (IIoT) integration. High-speed, secure, and flexible connectivity is essential to eliminate data silos and deliver real-time visibility across assets, systems, and locations. Modern industrial operations depend on unified data flows that enable faster response, higher reliability, and more resilient decision-making across distributed environments.

To support this reality, the latest release of ADISRA SmartView introduces meaningful enhancements to industrial driver connectivity, expanding platform flexibility, strengthening cybersecurity, and improving operational robustness across both Windows and Linux deployments.

Expanded Beckhoff TwinCAT ADS Connectivity

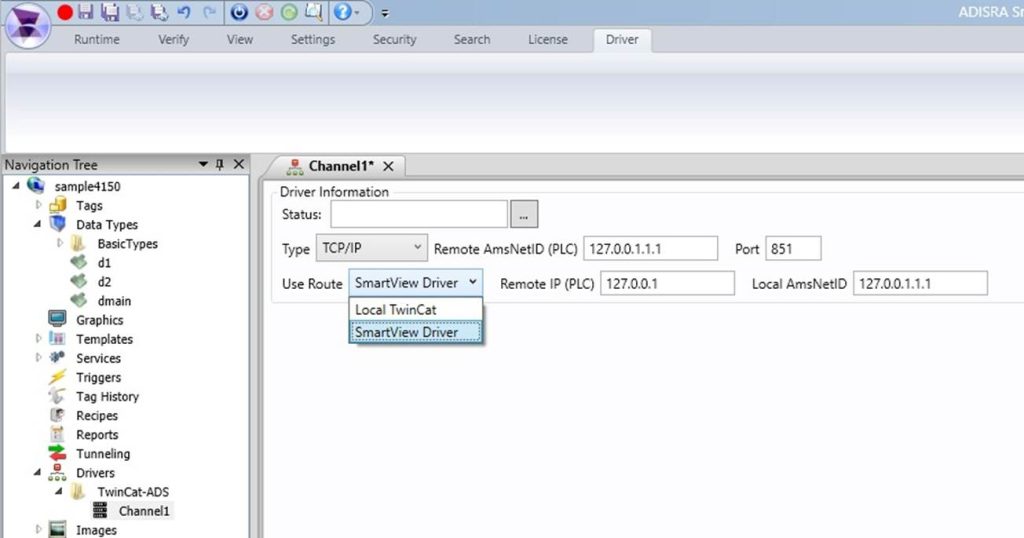

TwinCAT ADS (Automation Device Specification) is a core, proprietary communication technology from Beckhoff Automation that serves as the software backbone for Beckhoff industrial PCs. As this segment continues to grow rapidly, ADISRA has expanded its TwinCAT integration to better support modern deployment architectures.

ADISRA SmartView now supports a configurable TwinCAT TCP/IP router, enabling TwinCAT communication without requiring a local TwinCAT installation. In addition, the TwinCAT ADS driver has been updated to fully support Linux environments, providing functional parity with Microsoft Windows. These enhancements simplify system architecture, reduce dependency constraints, and support flexible edge and server-based deployments.

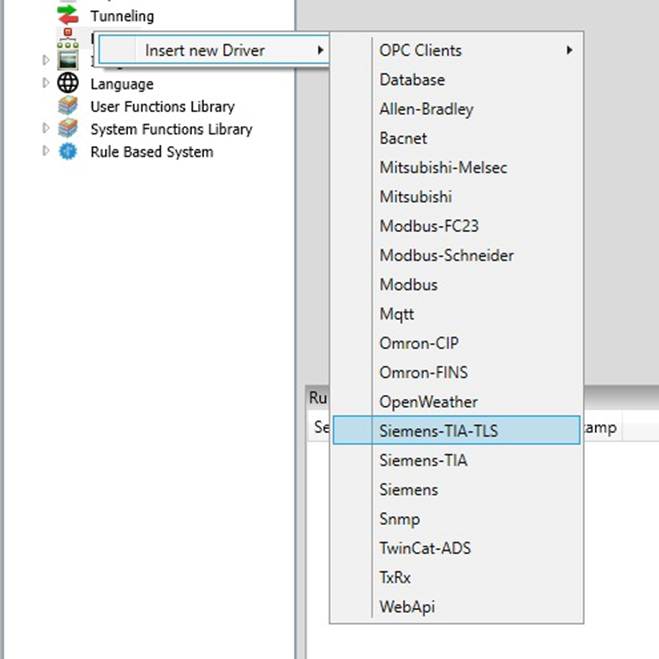

Enhanced Security for Siemens TIA Connectivity

Siemens Totally Integrated Automation (TIA) Portal provides a unified engineering environment for programming and managing Siemens PLCs and drives. Recognizing the increasing importance of cybersecurity in industrial systems, ADISRA has upgraded its Siemens TIA driver to support Transport Layer Security (TLS).

This update enables encrypted, certificate-based communication, aligned with modern Siemens TIA Portal versions, protecting data in transit and ensuring authenticated device communication. The result is a more secure integration between Siemens controllers and ADISRA SmartView, helping safeguard industrial networks against evolving cyber threats.

Driver Worksheet Usability Improvements

This release also introduces enhancements to driver worksheets that improve usability and operational efficiency:

– Sorting and filtering on driver sheets

New sorting and filtering capabilities allow users to navigate complex driver configurations more efficiently. This reduces cognitive load, accelerates troubleshooting, and improves overall system maintainability in large or highly distributed environments.

– Configurable driver start delay (milliseconds)

A configurable start delay aligns driver initialization with device startup timing. This prevents premature polling of PLCs or RTUs, reducing connection errors, false alarms, and resource contention, particularly in large systems or deployments with slower-booting hardware.

While these connectivity and driver enhancements strengthen ADISRA SmartView’s technical foundation, usability and visual clarity remain equally critical. The latest release also delivers targeted graphic enhancements that improve the overall user experience.

Improvement to the Symbol and Graphic Libraries for Faster, More Intuitive Engineering

Symbols and graphics have been foundational to HMI/SCADA systems since their transition from text-based terminals to PC-driven graphical interfaces. Over time, symbol libraries have become essential to efficient application development, enabling standardized visualization, reducing engineering effort, and improving operator situational awareness through consistent, reusable graphical objects. Pre-engineered symbols such as pumps, valves, motors, and gauges allow engineers to rapidly build screens that reflect real-time process conditions while supporting clear, intuitive operation.

As with all aspects of ADISRA SmartView, symbol and graphic capabilities continue to evolve based on real-world customer feedback. In ADISRA SmartView V4.1.5.0, several targeted enhancements have been introduced to improve usability, accelerate development, and streamline day-to-day engineering workflows.

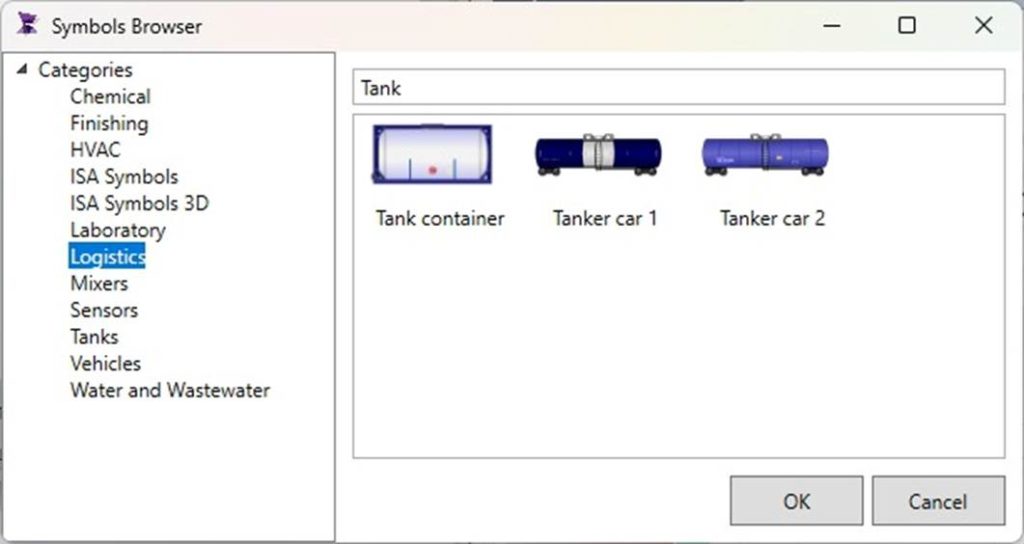

– Enhanced Symbol Search and Filtering

ADISRA SmartView now includes a filter capability in the Symbols dialog that supports case-insensitive, partial-text searches, dynamically filtering both folders and individual symbols. This enhancement significantly reduces the time required to locate specific graphical elements within large symbol libraries. By eliminating manual navigation through deeply nested folders, engineers can build and modify screens more efficiently, reducing development time and improving overall productivity in complex industrial applications.

– Streamlined Image Handling for Faster Screen Development

ADISRA SmartView now supports pasting images directly into the Graphics workspace, automatically creating Image objects with proper file handling and optional resize behavior. This enhancement removes manual import steps and ensures images are managed consistently within the application.

By enabling direct image pasting with intelligent handling, ADISRA SmartView significantly accelerates screen development and reduces engineering effort. Engineers can quickly incorporate equipment photos, layout diagrams, and floor maps into high-fidelity overview screens while maintaining image quality, predictable sizing, and efficient resource management, resulting in clearer visualization and more intuitive operator interfaces.

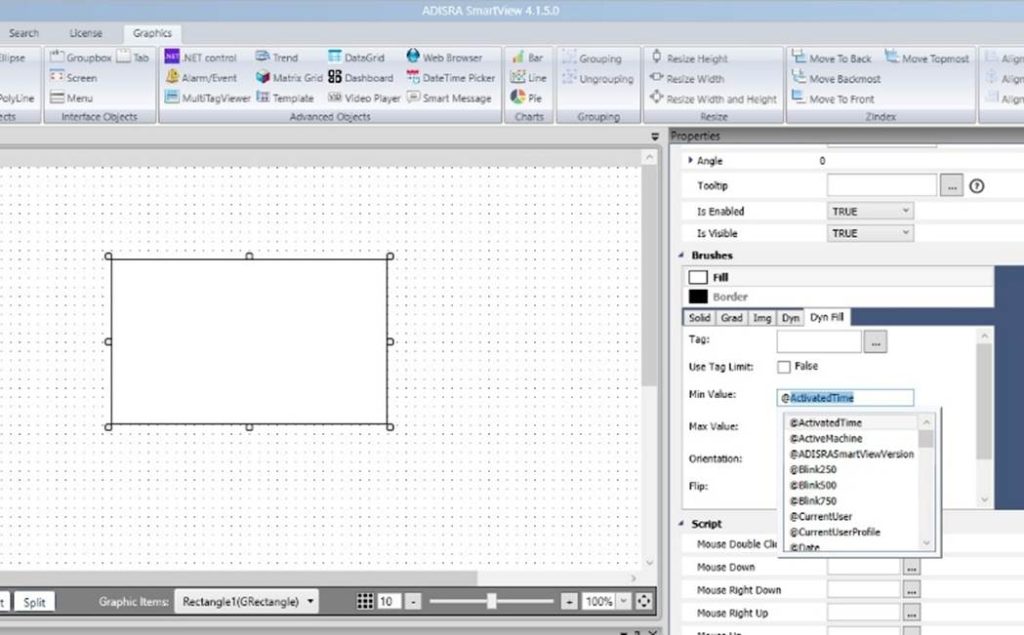

– Enhanced Dynamic Fill Control with Scaled Tag Ranges

ADISRA SmartView now allows tags used in Dynamic Fill to be configured with explicit minimum and maximum values for ellipse objects, supporting angular, vertical, and horizontal orientations. This enhancement provides greater control over how live data is visually represented on graphics.

By scaling raw tag values into meaningful visual ranges, this feature transforms low-level machine data into intuitive, real-time indicators, such as tank levels, pressure ranges, or capacity utilization. Operators gain faster comprehension of process conditions, while engineers benefit from cleaner configuration and more accurate visual mapping. The result is improved situational awareness, safer operation, and more confident, data-driven decision-making.

– Enhanced Dynamic Fill Control with Scaled Tag Ranges

ADISRA SmartView now allows tags used in Dynamic Fill to be configured with explicit minimum and maximum values for ellipse objects, supporting angular, vertical, and horizontal orientations. This enhancement provides greater control over how live data is visually represented on graphics.

By scaling raw tag values into meaningful visual ranges, this feature transforms low-level machine data into intuitive, real-time indicators, such as tank levels, pressure ranges, or capacity utilization. Operators gain faster comprehension of process conditions, while engineers benefit from cleaner configuration and more accurate visual mapping. The result is improved situational awareness, safer operation, and more confident, data-driven decision-making.

Several additional enhancements requested by users are also included in ADISRA SmartView V4.1.5.0.

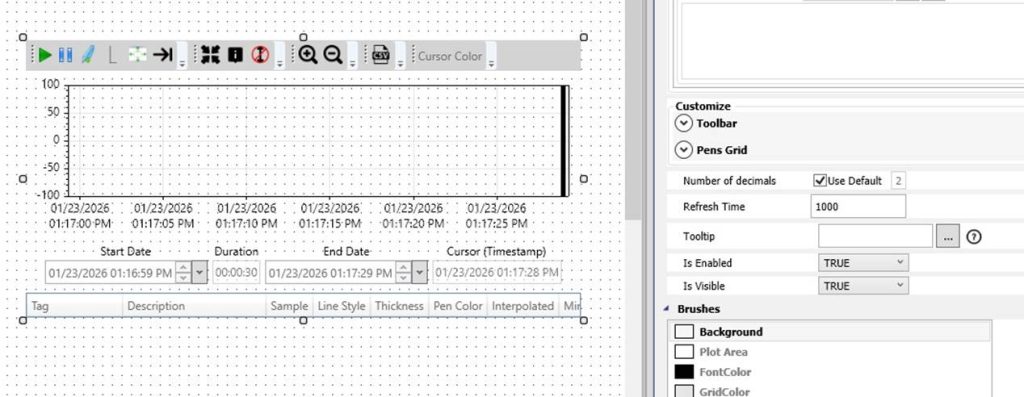

– Improved Trend Refresh Control for High-Speed Visibility

While SCADA graphics provide a snapshot of current conditions, trending delivers critical context by visualizing how processes change over time. Trend displays allow operators and engineers to identify patterns, detect anomalies, and anticipate potential issues before they impact operations.

ADISRA SmartView now includes a configurable refresh rate for Trend objects, with a minimum supported interval of 200 milliseconds. This enhancement allows trend displays to update up to five times per second, delivering high-fidelity visualization of fast-changing processes without compromising system performance.

By giving users control over trend refresh behavior, ADISRA SmartView enables more accurate diagnostics, faster response to transient events, and better insight into dynamic process behavior, particularly in applications involving high-speed equipment, energy monitoring, or rapidly fluctuating process variables.

– Faster Diagnostics with One-Click Access to DataWatcher

ADISRA SmartView now includes a shortcut button in the Remote Management Tool that opens DataWatcher, ADISRA SmartView’s built-in diagnostic and debugging utility, using the currently connected IP address. This enhancement eliminates the need for manual navigation and IP re-entry when troubleshooting remote systems.

In real-world deployments, especially across distributed plants or remote sites, rapid diagnosis is critical. One-click access to DataWatcher allows engineers and support teams to immediately inspect live tag values, communication status, and data integrity at the source. By reducing the time required to initiate diagnostics, this feature accelerates issue resolution, minimizes downtime, and improves the efficiency of remote support and maintenance operations.

– More Efficient Event Analysis with Flexible Message Filtering

ADISRA SmartView now supports filtering events by message content using partial-text matches, enabling faster and more flexible event searches. This enhancement allows users to quickly locate relevant event records without needing exact message text or rigid filter criteria.

In real-world HMI/SCADA environments, event logs capture time-stamped records of system activity, such as operator actions, configuration changes, and equipment state transitions, and serve as a critical source for auditing, diagnostics, and operational review. As event histories grow, manually scanning or narrowly filtering logs becomes time-consuming and error-prone.

Partial-message filtering dramatically reduces the time required to investigate incidents, validate operator actions, or support compliance reviews. Engineers and operators can rapidly isolate meaningful events, understand what occurred and when, and move from investigation to resolution more quickly and with greater confidence, without disrupting active operations.

Conclusion

Industrial operations continue to demand more from their HMI/SCADA platforms, greater connectivity, stronger security, faster diagnostics, and tools that reduce engineering effort without sacrificing performance. ADISRA SmartView V4.1.5.0 delivers on these expectations with targeted enhancements driven directly by real-world customer feedback.

From expanded Beckhoff and Siemens connectivity to improved driver usability, enhanced graphics workflows, faster trending, and streamlined diagnostics, this release strengthens ADISRA SmartView’s role as a modern, flexible foundation for intelligent industrial applications across Windows, Linux, edge, and distributed environments.

Download ADISRA SmartView V4.1.5.0 today to experience these improvements firsthand and see how they can simplify development, improve visibility, and accelerate decision-making in your next industrial project.

If you would like to see these new features in action, you can request a private demonstration here tailored to your specific use case or join us for the next ADISRA live webinar on Thursday, January 29, 2026.

During the webinar, we will demonstrate the new capabilities introduced in ADISRA SmartView V4.1.5.0, along with additional features commonly requested by customers and partners.

Webinar time:

9:30 a.m. CST

10:30 a.m. COT

12:30 p.m. BRT

3:30 p.m. UTC/GMT

4:30 p.m. CET

5:30 p.m. EET

11:30 a.m. MYT (Friday, January 30, 2026)

You can register for the webinar here.

The Linux Foundation and the Linux Foundation logo design are registered trademarks of The Linux Foundation. Linux is a registered trademark of Linus Torvalds.

Tux, the Linux kernel penguin mascot, was created by Larry Ewing in 1996 [lewing@isc.tamu.edu] using the GIMP [www.gimp.org] and is not owned by The Linux Foundation.

Microsoft, Windows, Windows 10X, Windows 11, and Windows Designs are trademarks of the Microsoft group of companies.

Siemens and Siemens TIA (TIA Portal): TIA Portal® is a registered trademark of Siemens Aktiengesellschaft.

Beckhoff®, TwinCAT®, TwinCAT/BSD®, TC/BSD®, EtherCAT®, EtherCAT G®, EtherCAT G10®, EtherCAT P®, Safety over EtherCAT®, TwinSAFE®, XFC®, XTS® and XPlanar® are registered and licensed trademarks of Beckhoff Automation GmbH.

ADISRA®, ADISRA’S logo, InsightView®, and KnowledgeView® are registered trademarks of ADISRA, LLC.

© 2026 ADISRA, LLC. All Rights Reserved.