Alarms: The First Line of Defense in Industrial Automation

Alarms serve as the first responders in industrial automation systems. Their core function is real-time monitoring, constantly observing system parameters to detect deviations or anomalies as they occur. Beyond detection, alarms act as an early warning system, alerting operators promptly to prevent minor issues from escalating into major disruptions.

The alarm function includes several essential features:

– Alarm Prioritization ranks alerts by severity, helping operators focus on the most critical issues first.

– Remote Notification ensures that operators receive alerts via email, SMS, or mobile application, regardless of their location.

– Alarm Logging records all events for historical analysis, helping identify patterns and improve long-term system reliability.

A Brief Look Back

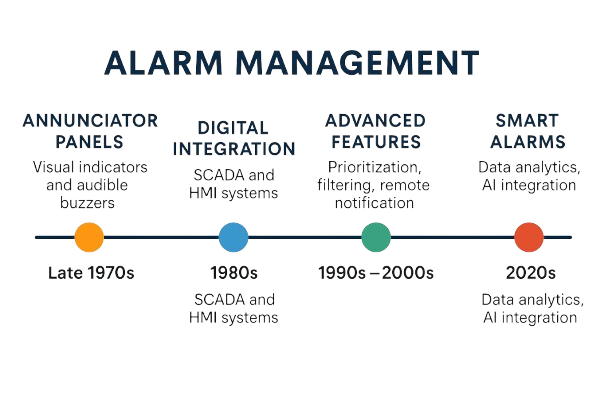

Alarms have been a part of industrial automation since the early days of annunciator panels, where illuminated indicators and audible buzzers alerted operators to system conditions. Each light on a panel represented a specific circuit or parameter, giving operators a visual map of system health.

With the advent of the Digital Integration era in the 1980s, alarm functionality shifted from physical hardware to computer-based SCADA and HMI systems. This transition brought significant gains in flexibility, functionality, and centralized monitoring.

The Evolution of Alarm Management

From the 1990s into the 2000s, alarm systems began to incorporate features that improved usability and effectiveness:

– Alarm Prioritization: Allowed critical alarms to rise above less urgent issues, improving operator response times.

– Alarm Filtering: Enabled filtering by equipment, location, or alarm type to avoid information overload.

– Remote Notification: Sent alerts via email or SMS, empowering operators to respond even when away from control rooms.

– Alarm Shelving: Temporarily suppressed known or non-critical alarms to reduce distractions.

– Alarm Logging: Provided detailed records of alarm events for compliance, diagnostics, and performance tuning.

The Era of Smart Alarms

Today, we are entering a new era of intelligent, data-driven alarm management. Smart alarms incorporate advanced analytics and AI to provide deeper insights and more responsive control. Emerging features include:

– Adaptive Learning: Automatically adjusts alarm thresholds based on historical patterns.

– Context-Aware Alarms: Enriches alarm notifications with relevant operational data.

– Automated Diagnostics: Triggers diagnostic routines upon alarm activation.

– Predictive Analytics: Uses trends and machine learning to anticipate potential issues.

– AI Integration: Enhances alarm handling with intelligent decision support.

While this future is exciting, the journey begins with understanding today’s capabilities. The next section will explore how ADISRA SmartView leverages modern alarm functions to deliver real-time awareness, operational efficiency, and scalability. Finally, we will examine how Smart Alarms may soon evolve within the ADISRA SmartView platform.

Alarm Management in ADISRA SmartView

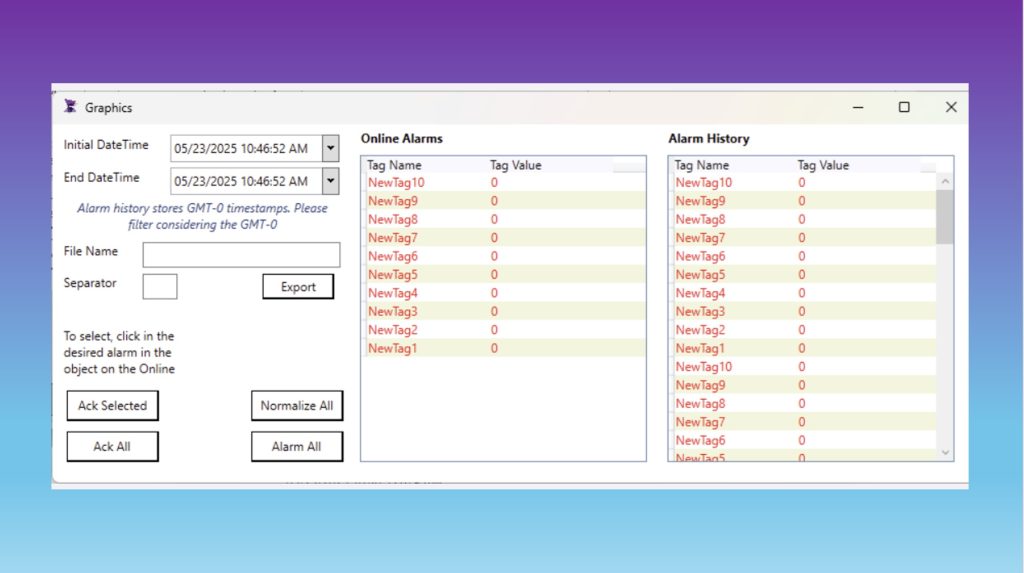

ADISRA SmartView offers a powerful and flexible alarm management system designed to streamline configuration, monitoring, and operator response. The Alarms module enables users to define alarm groups, associate tags, and configure specific alarm conditions and messages to meet project requirements.

At its core, the alarm system provides real-time alerts to notify operators of abnormal conditions or process deviations. These alerts empower users to take immediate corrective action, supporting plant safety, operational efficiency, and equipment reliability.

Core Capabilities

– Alarm Visualization & Notifications:

Alarms can be configured to display messages directly on the screen, send alerts via email or WhatsApp, and even trigger automated actions, such as adjusting process parameters or stopping equipment.

– Historical Logging:

Alarm events can be logged to a proprietary file system or stored in a connected database, allowing for long-term analysis, auditing, and compliance tracking. You can also export the alarm history to an Excel file based on a selected date and time range. An example of this functionality is available for download here.

– Group-Based Configuration:

Users can create multiple alarm groups with unique settings, such as custom message colors, independent logging behavior, and filtering options. Alarms can be logically grouped by asset, equipment, line, or system area to enhance operational visibility.

– Alarm Prioritization:

Assigning severity levels to alarms, such as LoLo, Lo, Hi, and HiHi—helps operators focus on the most urgent issues first. ADISRA SmartView also supports alarm types, including:

– Deviation Alarms: Trigger when a tag value moves outside a defined range.

– Freeze Alarms: Activate when a tag value remains unchanged beyond a defined deadband for a specific duration.

Visual prioritization is enhanced through color coding, optional animations for critical alarms, dynamic filtering, and precise timestamping, helping operators quickly assess the situation.

– Alarm Filtering:

To prevent information overload, ADISRA SmartView offers filtering tools that let users display only the most relevant alarms. Filters can be applied based on:

– Alarm group

– Priority level

– Alarm type (e.g., HiHi only)

– Status (e.g., only active and unacknowledged alarms)

– Tag name

This ensures operators can concentrate on critical events without being distracted by less important alerts.

This link lets you download a sample Alarm Filter project using ADISRA SmartView.

– Remote Notification:

ADISRA SmartView supports remote alarm notifications through multiple channels, including on-screen alerts, email, and WhatsApp messaging, so operators and maintenance teams can respond promptly even when off-site.

– Audio Alerts:

Audible alarms can be configured to play sound files when triggered. Users can define the sound file, volume, and playback duration, with options to mute the sound after acknowledgment. A demo is available here that showcases sound playback for any unacknowledged alarm state.

– Action-Based Responses:

Alarms can be linked to automated responses in addition to alerting operators. For example, ADISRA SmartView can trigger equipment shutdowns, switch modes, or initiate diagnostics based on alarm conditions.

ADISRA SmartView’s alarm module delivers a comprehensive, configurable, and scalable alarm management solution. Combining real-time monitoring, advanced filtering, multi-channel notifications, and automated actions ensures that operators remain informed, proactive, and in control, minimizing downtime and improving overall system performance.

Ready to explore on your own? Download ADISRA SmartView here.

The High Cost of Poor Alarm Management

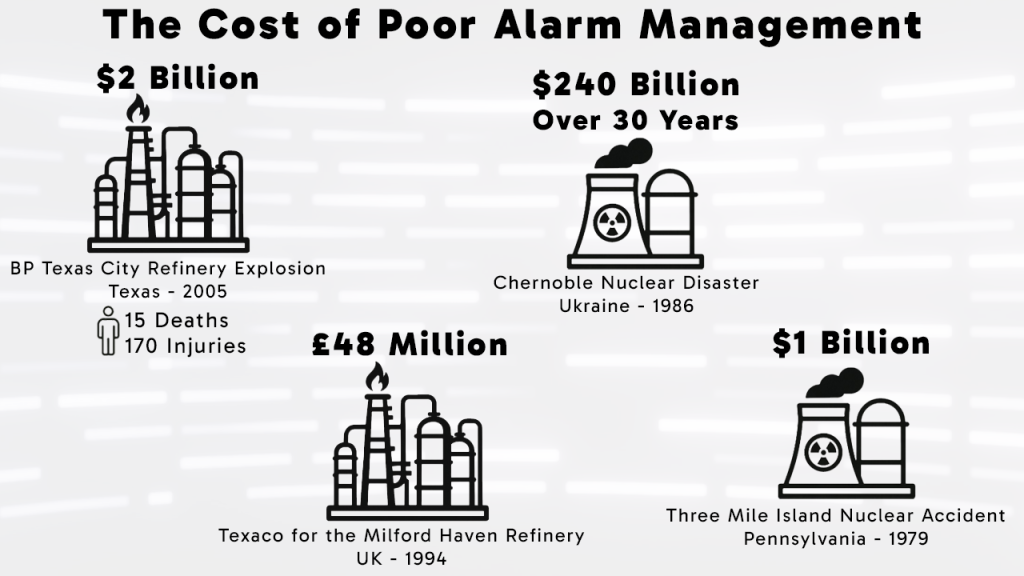

Ineffective alarm management is not just an operational inconvenience; it has been a significant contributing factor in some of the most catastrophic industrial accidents in history. These incidents illustrate how poorly designed or overloaded alarm systems can overwhelm operators, delay critical responses, and ultimately lead to loss of life, environmental damage, and billions in financial losses.

Notable Industrial Incidents Tied to Alarm Failures

– Texaco Refinery Explosion – Milford Haven, Wales (1994)

A massive explosion and fire occurred due to poor alarm system design. In the crucial moments leading up to the incident, operators were overwhelmed by a flood of alarms, many of which were either irrelevant or unprioritized. This alarm overload prevented timely, effective action.

– Three Mile Island Nuclear Accident – Pennsylvania, USA (1979)

During this partial meltdown, multiple design flaws in the alarm system, including poor presentation, lack of prioritization, and weak integration with other systems, contributed to operator confusion. Critical signals were missed or misunderstood, delaying the proper response.

– Chernobyl Nuclear Disaster – Ukraine (1986)

One of the worst industrial accidents in history, the Chernobyl disaster was worsened by alarm fatigue. Operators had become desensitized due to the frequent triggering of non-critical alarms, leading them to overlook or underestimate serious warnings. The tragedy also involved poor safety culture and reactor design flaws.

– BP Texas City Refinery Explosion – Texas, USA (2005)

This devastating accident caused 15 deaths, over 180 injuries, and $2.1 billion in damages. Investigations revealed that critical alarms were either non-functional or drowned in a sea of nuisance alerts. Operators failed to act on vital information, illustrating the dire consequences of unreliable alarm systems.

Alarm Standards That Shape Safer Systems

These incidents, though decades old, have had a lasting impact on industrial safety practices. In response, several international standards have emerged to guide the design, implementation, and management of alarm systems in HMI/SCADA software.

ANSI/ISA-18.2 – North American Standard

According to ISA-18.2, an alarm is defined as “an audible and/or visible means of indicating to the operator an equipment malfunction, process deviation, or abnormal condition requiring a response.” In other words, an alarm is not just a message or notification—it signifies a condition that demands timely and decisive operator intervention.

This standard outlines a complete alarm management lifecycle, covering philosophy development, system design, rationalization, implementation, operation, maintenance, and performance assessment. It emphasizes reducing nuisance alarms and improving operator situational awareness.

IEC 62682:2022 – International Alarm Management Standard

Published by the International Electrotechnical Commission (IEC), this standard aligns closely with ISA-18.2 and promotes the same lifecycle approach. It focuses on alarm systems integrated with control systems and HMIs in process industries, ensuring consistency across global operations.

EEMUA 191 – Best Practice Guidelines

Developed by the Engineering Equipment and Materials Users Association, EEMUA 191 provides comprehensive guidance for the design and management of alarm systems in industries such as power generation, oil and gas, and chemical processing. It is widely recognized for setting performance benchmarks, such as limiting alarm frequency to no more than one alarm every 10 minutes during steady-state operation, and recommending alarm prioritization with 5% high, 15% medium, and 80% low priority levels to prevent operator overload.

These standards serve as critical foundations for modern HMI/SCADA systems used in the process industry, including platforms like ADISRA SmartView, helping engineers and operators build alarm strategies that are effective, actionable, and compliant.

Conclusion

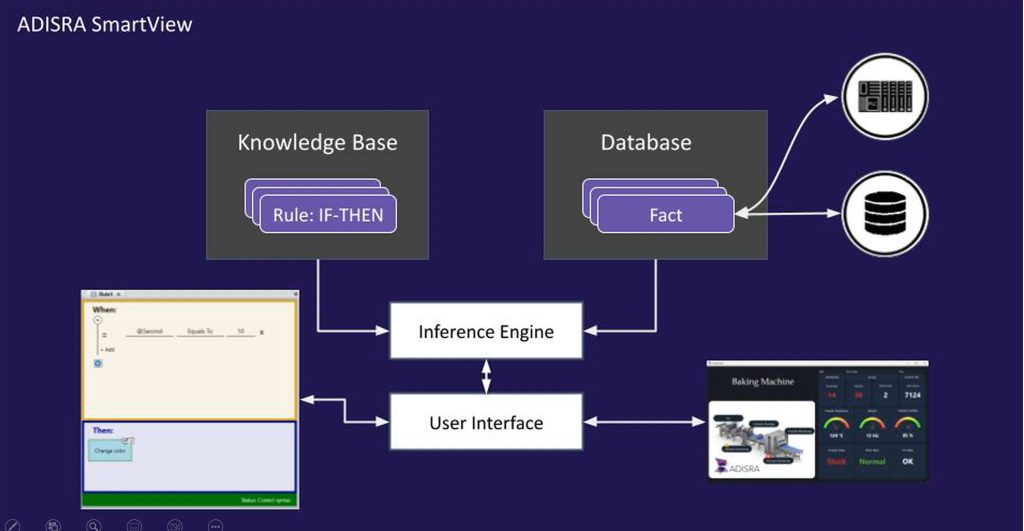

ADISRA SmartView, with its built-in rule-based expert system, brings a new level of intelligence to alarm management by enabling advanced filtering, prioritization, and correlation of alarm data. By applying predefined rules and expert knowledge, ADISRA SmartView can analyze incoming alarms, detect patterns, and recommend corrective actions, greatly enhancing operator response times and decision-making accuracy.

Smarter Alarm Handling Through Expert Systems

Encoding operational expertise into a structured set of rules allows ADISRA SmartView to assist operators in identifying and responding to critical alarms more effectively. This reduces the risk of human error and improves overall system reliability and efficiency.

One powerful application of this rule-based approach is root cause analysis. Rather than simply reacting to alarm symptoms, ADISRA SmartView can trace alarm sequences (activated rules) back to their origin, helping operators resolve underlying issues and prevent recurrence.

Built-In Diagnostic Guidance

The expert system can also provide real-time diagnostic support, offering clear, actionable instructions in response to specific alarm conditions. By embedding best practices and expert insights into the alarm logic, ADISRA SmartView ensures that operators can act quickly and confidently, even in complex or unfamiliar situations.

Looking Ahead: Machine Learning Integration

ADISRA SmartView’s ability to integrate third-party systems, including support for machine learning (ML) integration. This capability will allow the system to learn from historical alarm data, uncover hidden patterns, and adjust alarm thresholds, priorities, and guidance dynamically. The result is an adaptive, intelligent alarm system that continues to improve over time.

Try It Today

You can explore the power of ADISRA SmartView by downloading a free trial here. If you would like a personalized demo or want to attend a webinar, click this link. We would enjoy working with you and showing you how innovative alarm management can transform your operations.

Interested in more innovative industrial automation?

Join us for our upcoming webinar on June 24th at 9:30 AM CDT to explore how the built-in rule-based expert system in ADISRA SmartView transforms alarm management, diagnostics, and decision-making on the plant floor.

Webinar Title:

From Rules to Results: Harnessing the Power of Rule-Based Expert Systems in ADISRA SmartView

Discover how you can move from reactive operations to proactive performance using intelligent automation tools.

Register for the webinar here.

ADISRA®, ADISRA’s logo, InsightView®, and KnowledgeView® are registered trademarks of ADISRA, LLC.