Unplanned downtime in industrial automation can lead to substantial financial losses. These losses may stem from halted production, reduced efficiency, equipment damage, or even long-term reputational harm. While the exact impact varies by industry, company size, and equipment type, unplanned downtime consistently ranks among the most expensive operational disruptions, second only to safety incidents or environmental failures.

Minimizing these risks has become a strategic priority as organizations continue to embrace digital transformation. Predictive maintenance is emerging as a critical solution to increase uptime, improve reliability, and reduce the need for reactive repairs.

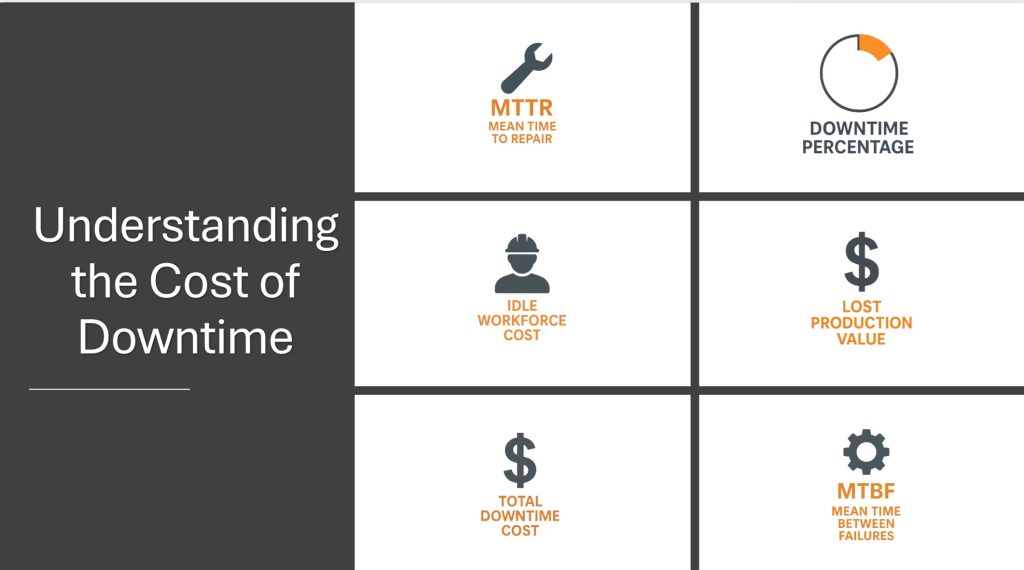

Understanding the Cost of Downtime

Before implementing a solution, companies must first understand how to quantify the impact of downtime. Several key metrics and formulas help paint a complete financial picture:

1. Downtime Percentage

Indicates the proportion of time equipment is unavailable:

Downtime Percentage = (Downtime / Planned Operating Time) × 100

2. Lost Production Value

Represents the revenue lost due to halted operations:

Lost Production Value = Units Not Produced × Profit Per Unit

Where:

• Units Not Produced = Downtime Hours × Avg. Production Rate

• Profit Per Unit = Revenue Per Unit – Variable Costs

3. Idle Workforce Cost

Calculates the cost of labor during unproductive hours:

Idle Workforce Cost = Avg. Hourly Wage × Downtime Hours × Number of Affected Employees

4. Total Downtime Cost

Represents the overall financial impact:

Total Downtime Cost = Lost Production Value + Idle Workforce Cost + Overhead Costs

While downtime percentage offers a high-level view, it does not reflect the frequency or duration of events. Metrics such as Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR) help organizations understand the underlying failure patterns and the responsiveness of their repair processes.

Ultimately, downtime is not just a number; it reflects lost productivity, profit, and opportunity.

What is Predictive Maintenance?

Predictive maintenance is a proactive strategy that uses data analysis and artificial intelligence to forecast equipment failures before they occur. By identifying potential breakdowns in advance, it enables timely interventions that minimize downtime and extend the life of assets.

At its core, predictive maintenance seeks to answer four fundamental questions:

• Will it fail?

• What will fail?

• When will it fail?

• Why will it fail?

This methodology can be applied to a single asset or scaled across the entire enterprise, depending on the organization’s operational goals.

Predictive Maintenance: A Strategic Response

To avoid the high costs of unplanned downtime, more companies are investing in predictive maintenance as a key pillar of operational excellence.

According to a March 2024 report by MarketsandMarkets™, the global predictive maintenance market is projected to grow from USD 10.6 billion in 2024 to USD 47.8 billion by 2029, reflecting a CAGR of 35.1%. This rapid growth is driven by advances in IoT sensors, real-time data connectivity, and AI-powered analytics that enable earlier and more accurate fault detection.

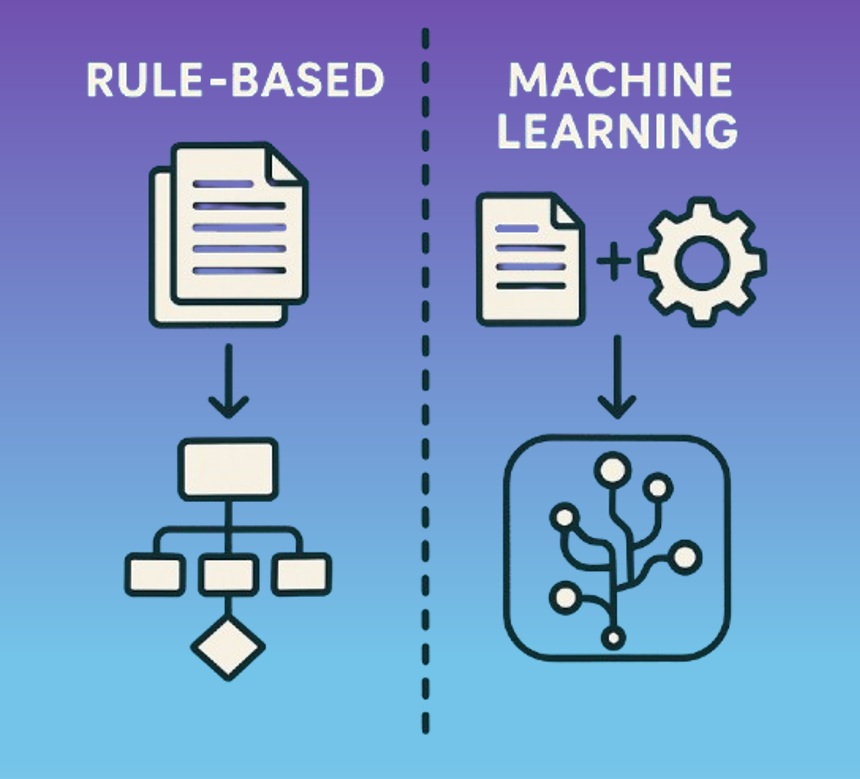

Rule-Based vs. Machine Learning Approaches

Predictive maintenance can be implemented using different technologies, each suited to specific needs:

• Rule-Based Expert Systems: These systems use predefined “if-then” logic and thresholds to detect known conditions. They work best in well-understood, stable environments with clearly defined failure patterns.

• Machine Learning (ML): ML models analyze large datasets to identify complex patterns and predict failures in dynamic environments. They are particularly effective when equipment behavior varies or failure modes are less predictable.

Many modern organizations combine these approaches to build hybrid systems, leveraging the clarity and control of rules with the adaptability and intelligence of machine learning.

In the following sections, we will explore predictive maintenance through both the rule-based and machine learning lenses using ADISRA SmartView and KnowledgeView. You will learn how each method works, when to use them, and how combining the two can form a powerful strategy for reducing costly downtime.

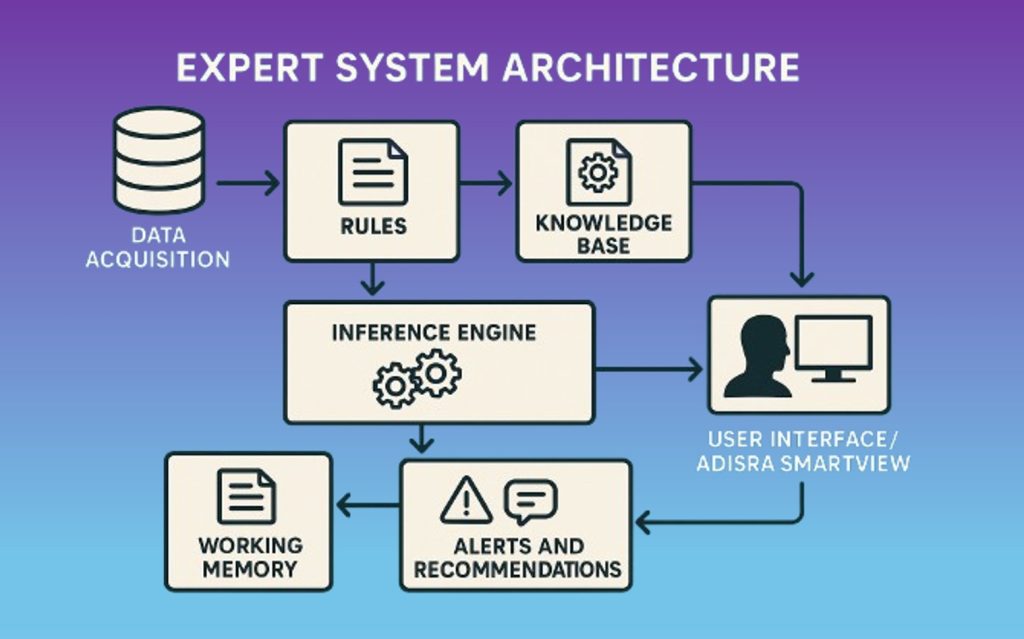

Understanding Rule-Based Expert Systems in Predictive Maintenance

An expert system is a type of Artificial Intelligence that uses predefined rules, often structured as “if-then” statements, to make decisions or solve problems. These systems replicate human expertise by applying logical rules to input data, generating conclusions or recommendations. While expert systems have been widely used across various industries for their simplicity and cost-effectiveness, they lack the adaptability of machine learning-based predictive models. In this section of the blog, we will first explore the key components of a rule-based expert system and then demonstrate how ADISRA SmartView can be used to implement one for predictive maintenance.

Components of a Rule-Based Expert System

A rule-based expert system typically includes the following key components:

1. Data Acquisition

The system collects real-time data from sensors, programmable logic controllers (PLCs), or edge devices to monitor asset conditions.

2. Rules

Rules define the system’s logic using “IF-THEN” statements to guide decision-making based on input data.

Example (for predictive maintenance of motors):

IF

Motor temperature > 85°C

AND Vibration level > 4 mm/s RMS

AND Runtime > 8 hours continuously

THEN

Trigger alert: “Potential motor overheating. Inspect cooling system and motor bearings.”

Log maintenance recommendation

Notify maintenance team

3. Knowledge Base

This is the central repository of rules and known facts, built from expert input or industry documentation.

4. Inference Engine

The inference engine applies the rules from the knowledge base to incoming data, evaluates conditions, and determines appropriate actions.

5. Working Memory

This component holds current, real-time data and updates as new inputs are received and processed.

6. Alerts and Recommendations

When abnormal conditions are detected, the system generates alerts and suggests maintenance actions to prevent failures.

7. User Interface

This is how users interact with the system, entering data, visualizing issues with the assets, and receiving alerts. In ADISRA SmartView, the SCADA/HMI environment serves as this interface, allowing users to build, monitor, and manage expert systems visually and in real time.

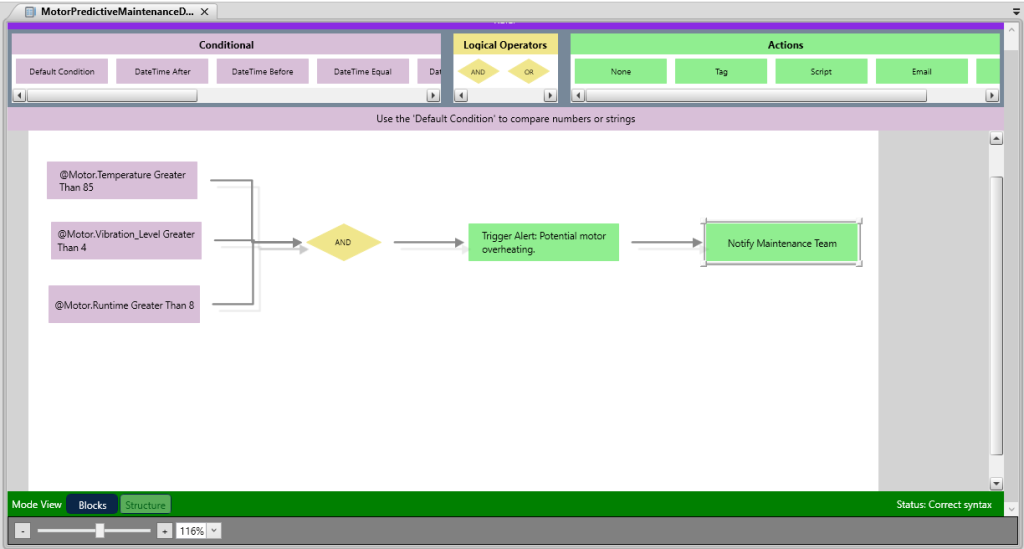

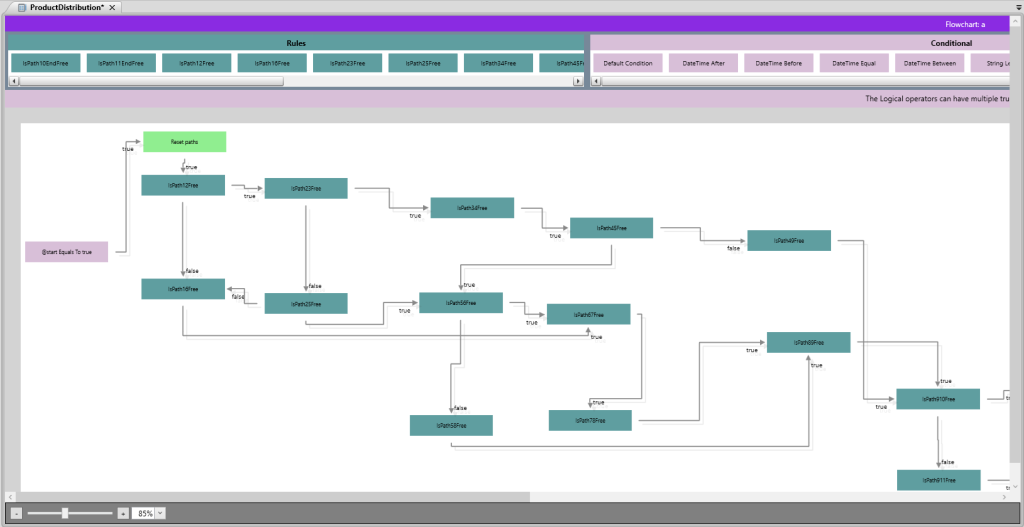

Using ADISRA SmartView for Predictive Maintenance

Most machines on the shop floor are designed to report failures only after they occur, not to predict them. Traditional control systems collect and process data in real time, while HMI and SCADA platforms are typically focused on displaying current or historical information. ADISRA set out to change that by empowering users to take a proactive approach, using rule-based analytics to anticipate issues before they lead to downtime.

ADISRA SmartView provides an intuitive platform for developing rule-based expert systems directly within the HMI/SCADA environment, making it ideal for predictive maintenance of critical assets like electric motors.

These expert systems are most effective when built on well-defined domain knowledge, whether from experienced technicians or detailed maintenance documentation. One of their key advantages is transparency: the decision logic is easy to understand, trace, and update, an essential feature in environments where speed, accuracy, and consistency are critical.

With ADISRA SmartView, users can define rules to monitor key motor health indicators such as temperature, vibration, current draw, and runtime. When any of these metrics exceed set thresholds, ADISRA SmartView can automatically trigger alarms, log events, and notify maintenance personnel, helping to prevent costly unplanned downtime.

Example: Motor Predictive Maintenance Using Rules

Let us revisit the motor monitoring scenario. Using ADISRA SmartView’s rule-based expert system module, you can define logic such as:

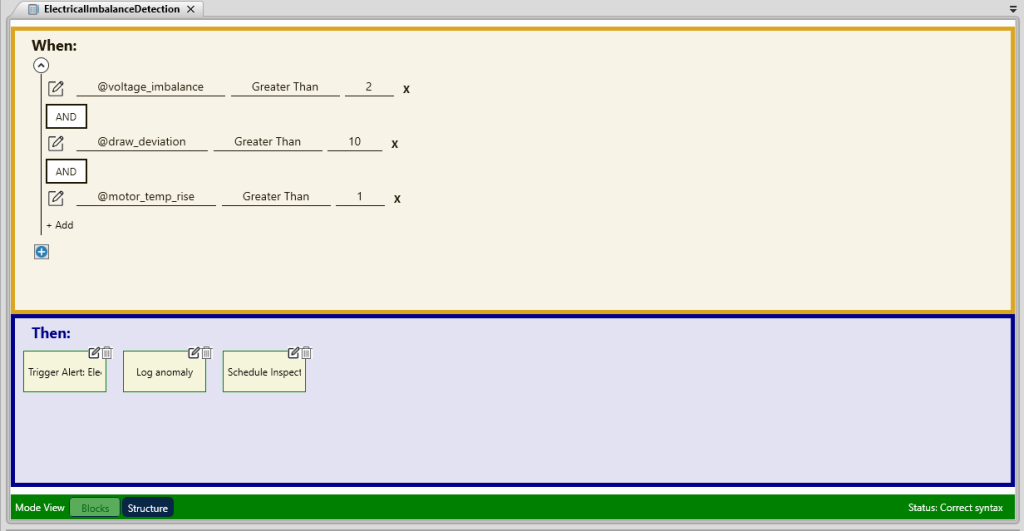

Rule: Electrical Imbalance Detection

IF

Voltage imbalance between motor phases > 2%

AND Current draw deviation between phases > 10%

AND Motor temperature rising over time (slope > 1°C/min)

THEN

Trigger alert: “Possible electrical imbalance. Check power supply and motor windings.”

Log anomaly with timestamp and sensor data

Schedule inspection task for the maintenance team

These rules are implemented using ADISRA SmartView’s built-in tools, with data collected from PLCs, sensors, or edge devices via standard industrial protocols such as Modbus, OPC UA, or MQTT.

Advantages of Rule-Based Expert Systems

– Transparency: Logic is explicit and easily auditable.

– Ease of Implementation: No historical data is needed, ideal for well-defined problems.

– Consistency: Decisions are repeatable and predictable.

– Flexibility: Rules can be updated or expanded as new knowledge emerges.

Limitations of Rule-Based Systems

– Scalability: Large rule sets can become difficult to manage.

– No Learning Capability: Systems do not adapt unless rules are manually updated.

– Rigidity: Less effective when dealing with uncertainty or changing conditions.

Whether monitoring one motor, or multiple assets, ADISRA SmartView enables teams to move from reactive to predictive maintenance, reducing downtime, extending equipment life, and improving operational efficiency.

That said, rule-based systems alone cannot adapt to evolving data patterns. This is where machine learning (ML) provides a powerful enhancement, offering adaptability, pattern recognition, and continuous improvement. In the next section, we will explore how ADISRA KnowledgeView brings ML into predictive maintenance strategies.

Try ADISRA SmartView today by downloading a free trial from our website here.

Using Machine Learning for Predictive Maintenance

While rule-based expert systems are effective for well-defined conditions, they fall short when dealing with complex, variable environments where failure patterns are not always obvious. This is where machine learning (ML) excels.

Machine learning brings adaptability to predictive maintenance by analyzing large volumes of historical and real-time data to uncover hidden patterns, detect anomalies, and predict equipment failures before they occur, often with greater accuracy and fewer false alarms.

Unlike static rules, ML models continuously learn and improve over time, making them especially valuable in dynamic industrial settings where operating conditions evolve and equipment behavior may change.

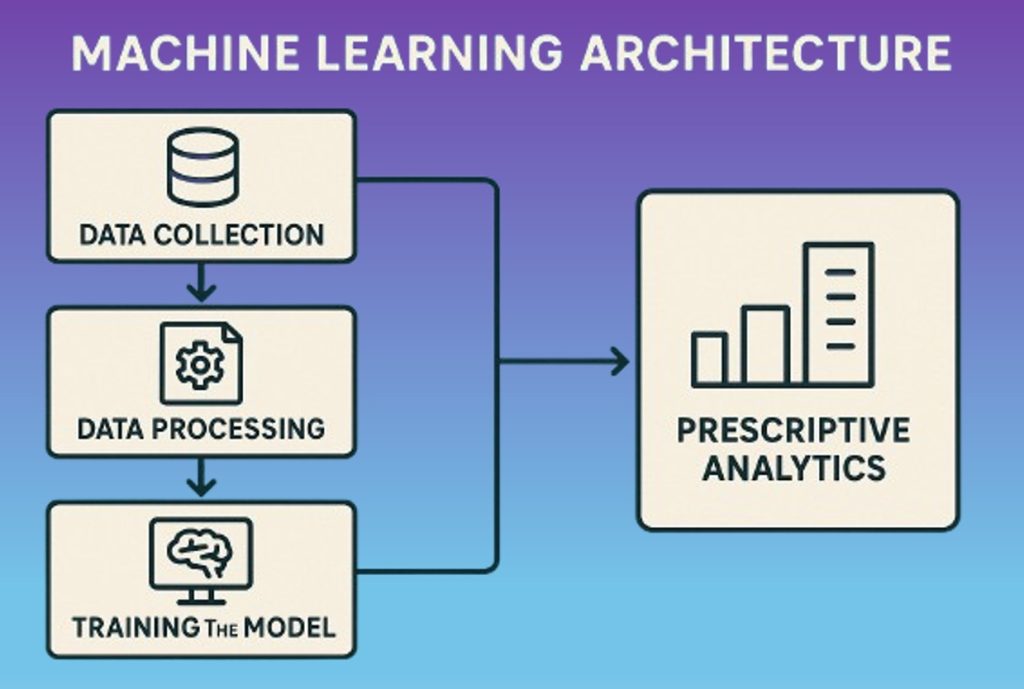

Steps for Implementing Machine Learning in Predictive Maintenance

The steps to using machine learning for industrial predictive maintenance involve collecting data, training AI models, monitoring in real-time, and taking action. Let us delve into the details of each of these steps.

- Data Collection

The first step in implementing machine learning for predictive maintenance is collecting data from sensors, control systems, and historical records. This includes equipment health metrics, operating conditions, and environmental variables. However, raw data alone is not enough; it must be properly processed and prepared before it can be used effectively in predictive models.

2) Data Processing

Once collected, the raw data must be cleaned, structured, and organized for analysis. This involves identifying and extracting relevant features that reflect equipment performance and health. Effective data processing is critical because poor-quality data leads to unreliable insights and flawed models.

Not all data is created equal. Some data is structured, highly organized and easily processed by traditional machine learning algorithms. Other data is unstructured, making up approximately 80% of all generated data. Unstructured data includes sources such as video, and audio. Unlike structured data, it does not follow a predefined format and typically resides in non-relational databases.

The key difference between the two lies in ease of analysis. Structured data, being tabular and orderly, can be handled with conventional tools. Unstructured data requires more advanced techniques such as pattern recognition, classification algorithms, and text mining to extract meaning.

For organizations aiming to achieve digital transformation, it is essential to harness both types of data. Focusing only on structured sources limits visibility and reduces the depth of insights machine learning can provide.

Data cleansing is a crucial part of this process. It involves identifying and correcting inaccurate, duplicate, or incomplete data entries. When multiple data sources are integrated, inconsistencies often arise. Cleansing ensures that the inputs to your machine learning models are accurate and trustworthy, because the quality of your insights depends on the quality of your data. This stage is not about altering the data to influence outcomes, but rather about ensuring it is clean, consistent, and usable.

3) Training the Model

Once the data has been collected and processed, the next step is training a machine learning model. This is where algorithms come into play; they are the engines that turn raw data into predictive insights.

The choice of algorithm depends on several factors, including the nature of the problem, the type and structure of the data, and the available computational resources. Common machine learning algorithms include neural networks, decision trees, Bayesian classifiers, and clustering methods such as K-means. Each has its own strengths and ideal use cases. Some are excellent at identifying subtle patterns (e.g., consumer behavior), while others excel at large-scale classification (e.g., image recognition in Google Photos).

To better understand how these models are trained, let us look at the three main learning styles:

Supervised Learning

In supervised learning, the algorithm is trained on a labeled dataset, where the input data is paired with the correct output. The goal is to learn the mapping from inputs to outputs, enabling the model to make predictions on new, unseen data.

Example: Training a model to recognize robots in images. Each training image is labeled “robot,” and over time, the model learns to distinguish robots from other objects.

Common supervised algorithms include decision trees, logistic regression, random forests, and backpropagation-based neural networks.

Unsupervised Learning

In unsupervised learning, the algorithm is given input data without labeled outcomes. It must identify patterns, groupings, or anomalies on its own.

Example: Feeding thousands of robot images to a model without telling it which images contain robots. The model might detect similarities in shape, size, or mobility and organize the data accordingly—e.g., grouping by number of limbs or movement type.

Clustering and dimensionality reduction techniques like K-means or Principal Component Analysis (PCA) are often used here.

Semi-Supervised Learning

This approach blends the two above: a small amount of labeled data combined with a larger pool of unlabeled data. It is useful when acquiring labels is expensive or time-consuming.

Popular Predictive Maintenance Algorithms

Here are four types of algorithms frequently used in predictive maintenance:

– Anomaly Detection

Identifies data points or behaviors that deviate from the norm. This is useful for flagging equipment behaviors that suggest an impending failure.

– Classification

Assigns labels to input data (e.g., “normal” vs. “faulty”).

Binary classification (e.g., spam vs. not spam in email Spam detection) is straightforward and common.

– Multi-class classification allows for three or more categories. For instance, an ML model might categorize machine faults by type, electrical, mechanical, or hydraulic, based on sensor data.

– Regression

Predicts continuous outcomes.

Example: Estimating the remaining useful life (RUL) of a motor based on operating temperature, runtime, and vibration levels. Regression models calculate a real-valued output (e.g., “36 hours left”) rather than a category.

Prescriptive Analytics

While not an algorithm itself, prescriptive analytics builds on predictions by suggesting or automating the best course of action.

According to Gartner, prescriptive analytics applies logic and mathematics to recommend decisions. It can:

– Send automated maintenance requests with recommended next steps.

– Trigger control system actions based on predicted failures.

There are two main methods for enabling prescriptive analytics:

– Optimization techniques (e.g., linear programming)

– Computational logic (e.g., predefined business or maintenance rules)

A Few Final Considerations

Predictive analytics is inherently probabilistic. No model, no matter how sophisticated, can forecast every failure. For example, a forklift collision with a machine is a user error that no algorithm can foresee. These limitations are part of the reality of predictive modeling.

That said, a well-trained model can significantly improve operational reliability by catching the vast majority of preventable failures. As philosopher Carveth Read once said, “It is better to be vaguely right than exactly wrong.” In today’s world of big data, the goal is to increase the odds of being right, often enough to make a real business impact.

And remember: your model is only as good as the data it is built on. Models should be regularly retrained and updated to reflect changing conditions, new inputs, and evolving failure modes. The more accurate and relevant your data, the more reliable your predictions will be.

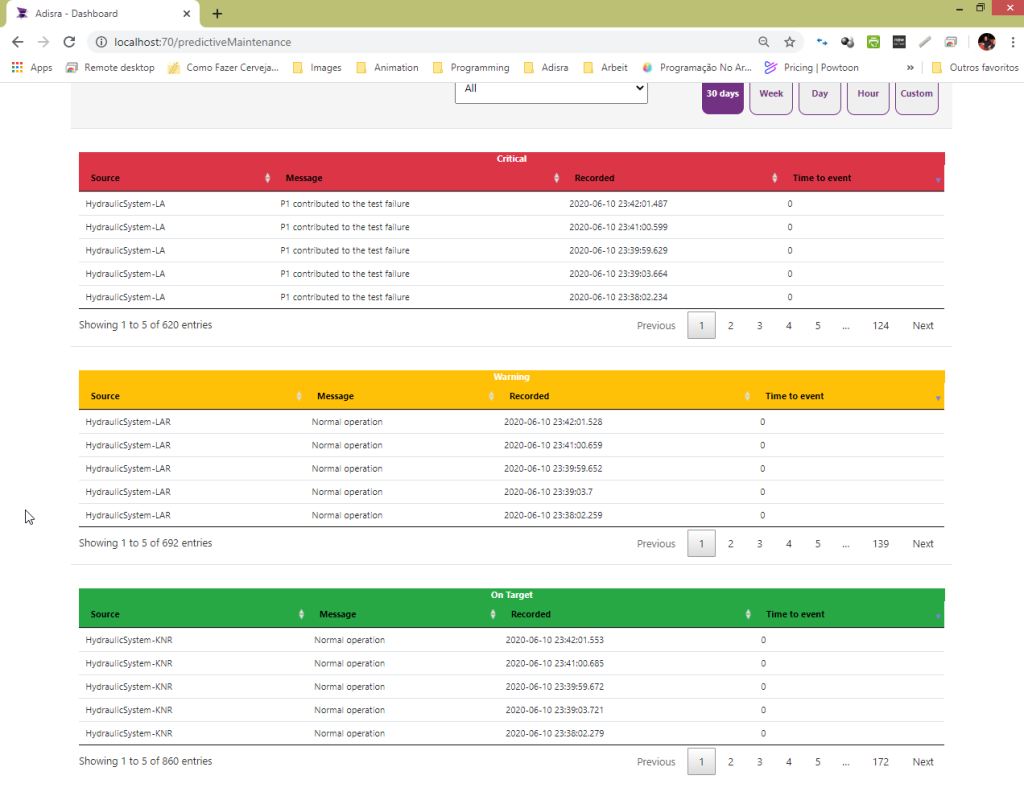

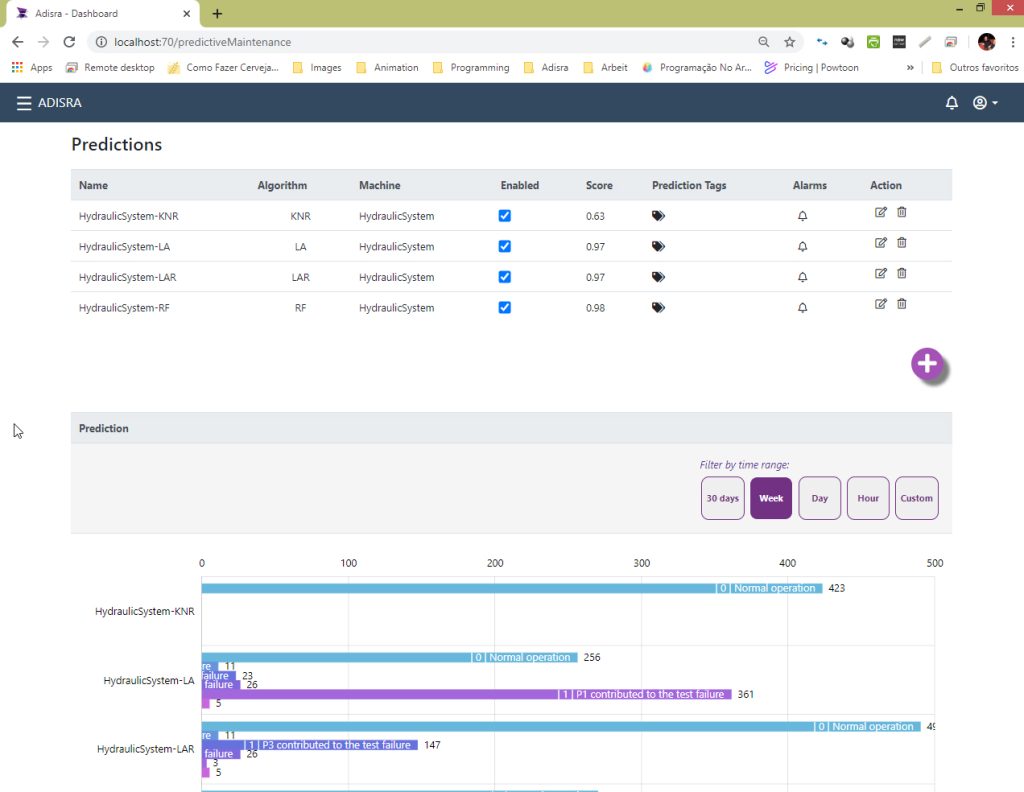

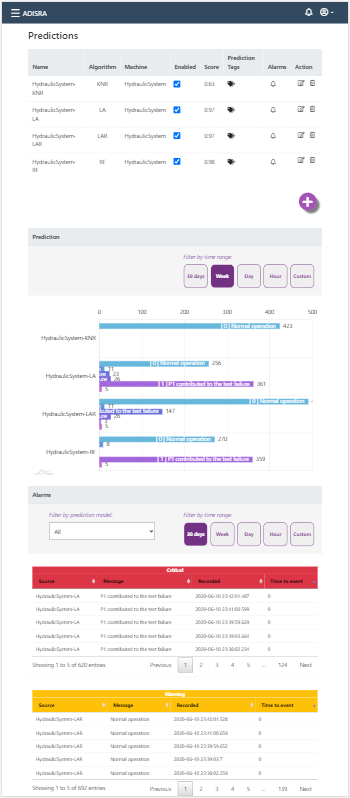

ADISRA KnowledgeView: Cloud-Powered Predictive Maintenance

ADISRA KnowledgeView is a cloud-based platform designed to bring the power of predictive analytics to industrial operations. Built for scalability, performance, and accessibility, it enables organizations to move beyond reactive maintenance and toward data-driven decision-making.

ADISRA chose a cloud architecture for KnowledgeView because of the unique advantages it offers:

– Scalable Storage – Seamlessly store and manage large volumes of real-time and historical data.

– High-Performance Processing – Run complex machine learning models with speed and efficiency.

– Anywhere Access – Gain visibility and insights from any location, on any device.

– Cost Efficiency – Eliminate the need for significant upfront investments with flexible, pay-as-you-go pricing.

– Continuous Improvement – Easily retrain and update models to reflect evolving equipment behavior.

In many cases, organizations adopt a hybrid approach by combining on-premises solutions, such as ADISRA SmartView, equipped with rule-based expert systems, with the advanced cloud analytics capabilities of KnowledgeView. This model strikes the right balance between local control and the power of scalable cloud computing.

KnowledgeView uses advanced machine learning techniques, including anomaly detection and both supervised and unsupervised learning, to detect subtle patterns in equipment data. These insights are used to forecast potential failures, outages, or performance degradation, often before any obvious signs of trouble appear.

By delivering real-time insights and predictive recommendations, ADISRA KnowledgeView helps users extend asset life, reduce downtime, and make smarter, faster maintenance decisions. The goal is simple but powerful: intervene before failure occurs.

Request a temporary account on our website here to explore a live predictive maintenance demo for a Hydraulic Compressor.

Why Predictive Maintenance Is No Longer Optional

Unplanned downtime is no longer just an inconvenience; it is a direct threat to profitability, efficiency, and competitiveness. From lost production and idle labor to long-term asset degradation, the cost implications are significant. As industries become more connected and data-rich, companies must shift from reactive to proactive maintenance strategies.

Predictive maintenance offers a path forward, one that is both measurable and transformative. Whether you are using rule-based expert systems for fast, transparent decisions or deploying machine learning for deeper insights and adaptability, the goal remains the same:

Anticipate failure before it happens.

With ADISRA SmartView and KnowledgeView, industrial teams can build a hybrid predictive maintenance solution that is powerful, practical, and scalable. By combining real-time, rule-based alerts with cloud-based machine learning analytics, organizations gain both control and intelligence, maximizing uptime while minimizing costs.

The future of maintenance is not just predictive, it is strategic, data-driven, and more innovative than ever.

Download ADISRA SmartView today to start building your predictive maintenance system. Then, request a temporary account on our website to explore KnowledgeView in action.

Interested in learning more about Rule-based Expert Systems?

Join us for our upcoming webinar on June 24th at 9:30 AM CDT to explore how the built-in rule-based expert system in ADISRA SmartView transforms alarm management, diagnostics, and decision-making on the plant floor.

Webinar Title:

From Rules to Results: Harnessing the Power of Rule-Based Expert Systems in ADISRA SmartView

Discover how to transition from reactive operations to proactive performance with intelligent automation tools.

Register for the webinar here.

ADISRA®, ADISRA’s logo, InsightView®, and KnowledgeView® are registered trademarks of ADISRA, LLC.

Copyright

© 2025 ADISRA, LLC. All Rights Reserved.