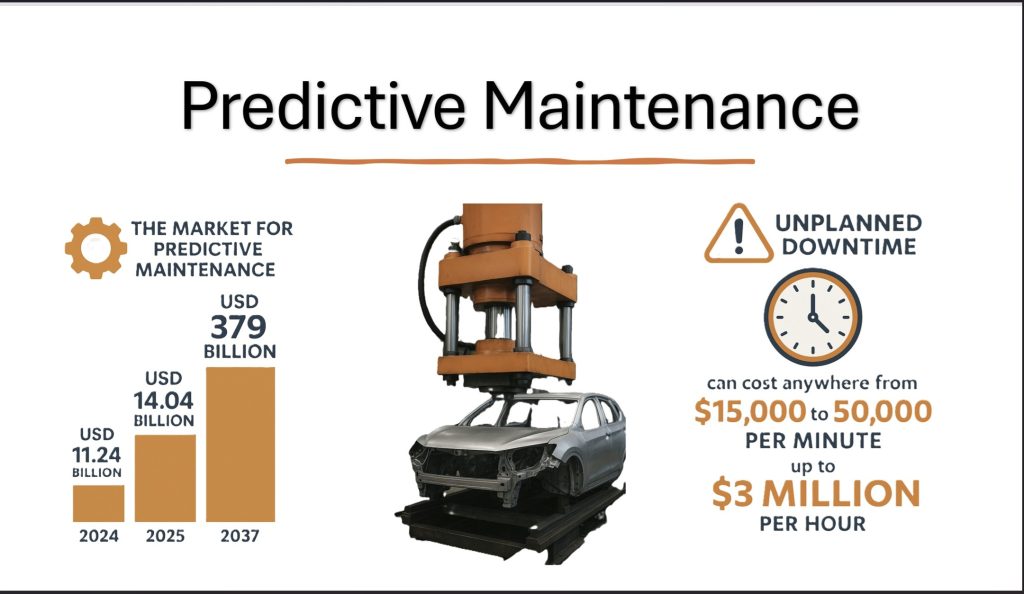

A major automotive vendor once told me that unplanned downtime can cost anywhere from $15,000 to $50,000 per minute, up to $3 million per hour. Numbers like that underscore the critical importance of minimizing disruptions in industrial operations. For software providers, it highlights the responsibility to deliver reliable, high-quality solutions that help customers avoid costly interruptions.

This is where predictive maintenance provides measurable value. By analyzing equipment data and identifying the optimal time for service, predictive strategies reduce unplanned downtime, extend asset life, and make maintenance procedures more cost-effective. The result is greater efficiency, reduced waste, and significant cost savings, transforming maintenance from a reactive expense into a proactive business advantage.

The global demand for smarter factories is fueling rapid growth in predictive maintenance. A Research Nester report (May 8, 2025) valued the market at USD 14.04 billion in 2025, up from USD 11.24 billion in 2024. Even more impressive, it is expected to surge past USD 379 billion by 2037, growing at a staggering 31% CAGR.

Predictive Maintenance on the Factory Floor

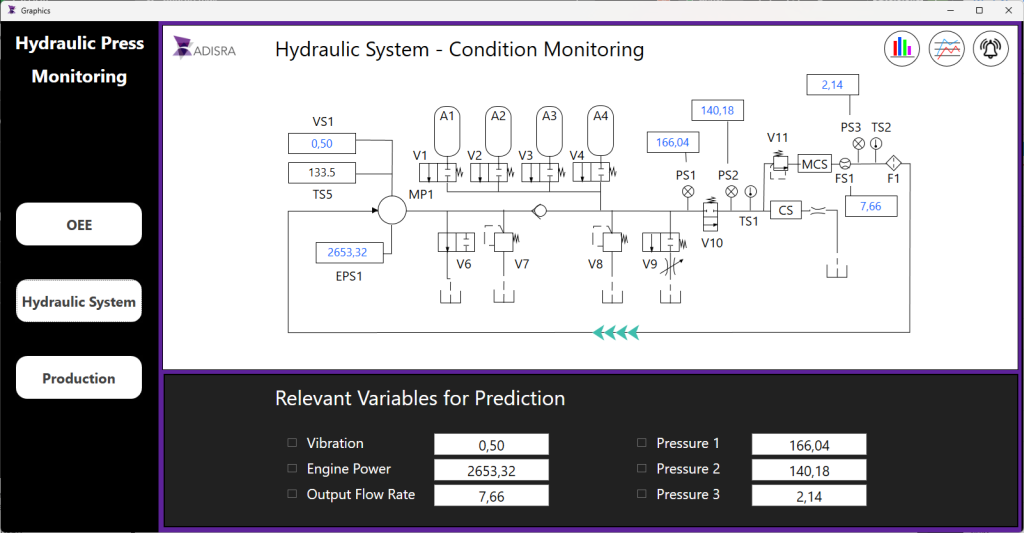

What does this look like in practice? Consider the hydraulic press, a critical component in automotive manufacturing. These systems are prone to issues such as oil leakage, pressure instability, overheating, insufficient fluid levels, slow operation, and wear of seals, pumps, and filters, all of which can lead to costly downtime if left unaddressed.

When designing a predictive maintenance strategy, one key question is: what data should be measured, and how can it reveal early signs of wear and tear? In hydraulic systems, wear is one of the biggest concerns, yet it is difficult to measure directly. That is why manufacturers rely on indirect indicators gathered from multiple sensors.

For example:

- Leaks in pumps and motors can be detected using flow sensors, but the readings must be considered alongside pressure, speed, and temperature to build an accurate picture of equipment health.

- Cavitation, a common issue caused by air or contaminants forming bubbles in the hydraulic fluid, can be detected with vibration and sound sensors. If left unchecked, cavitation can damage components and shorten equipment lifespan, but early detection allows operators to intervene before major damage occurs.

ADISRA’s Hybrid Approach

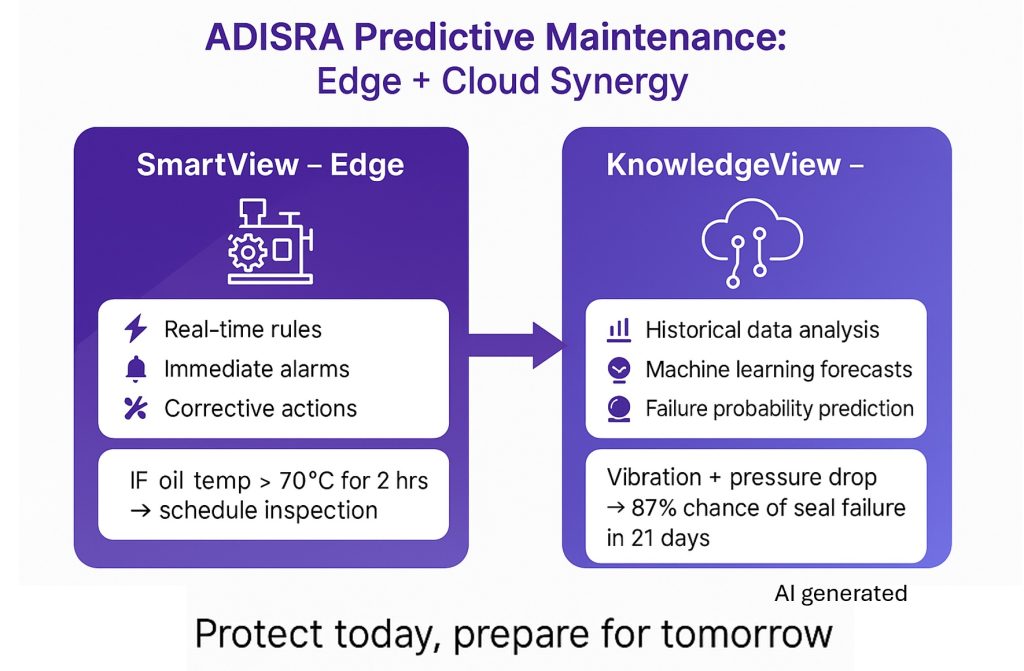

This is where ADISRA’s hybrid approach comes in. On the hydraulic press line, ADISRA SmartView utilizes a rule-based expert system diagnostics at the edge, leveraging sensor inputs to identify and flag known issues, such as rising oil temperature, abnormal vibration, or pressure loss. Meanwhile, KnowledgeView leverages cloud-based machine learning, analyzing historical and real-time data to uncover subtle fault patterns that rules alone may not catch.

Together, they form a powerful predictive maintenance strategy:

– Rules deliver immediate, actionable insights on the shop floor.

– Machine learning refines long-term predictions and continuously improves system performance.

Rules vs. Machine Learning

Traditionally, fault diagnosis falls into two main categories:

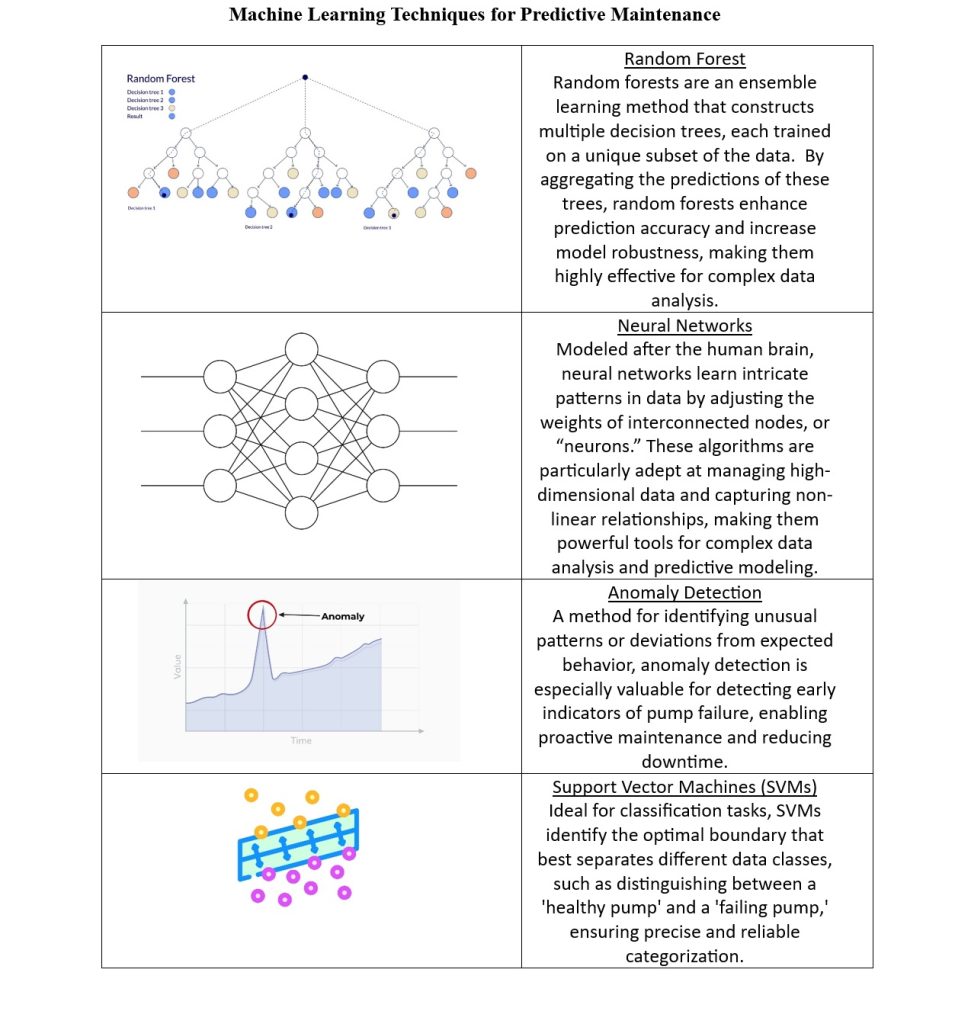

– Rule-Based Expert Systems

These rely on predefined conditions to detect anomalies. They are highly effective for catching known issues, such as vibration thresholds or temperature limits, but are less flexible when new or unexpected fault types arise.

– Machine Learning Algorithms

These excel at uncovering hidden patterns in equipment data, offering powerful insights that go beyond what rules can capture. However, they require large volumes of historical failure data, which may not always be available in the early stages of equipment operation.

ADISRA bridges these two worlds. With ADISRA SmartView, manufacturers can deploy rule-based expert system diagnostics directly at the edge for instant visibility into conditions such as abnormal vibrations or temperature spikes. KnowledgeView, meanwhile, utilizes cloud-based machine learning to identify emerging fault patterns and continually refine predictive accuracy.

ADISRA SmartView for Hydraulic Press Predictive Maintenance

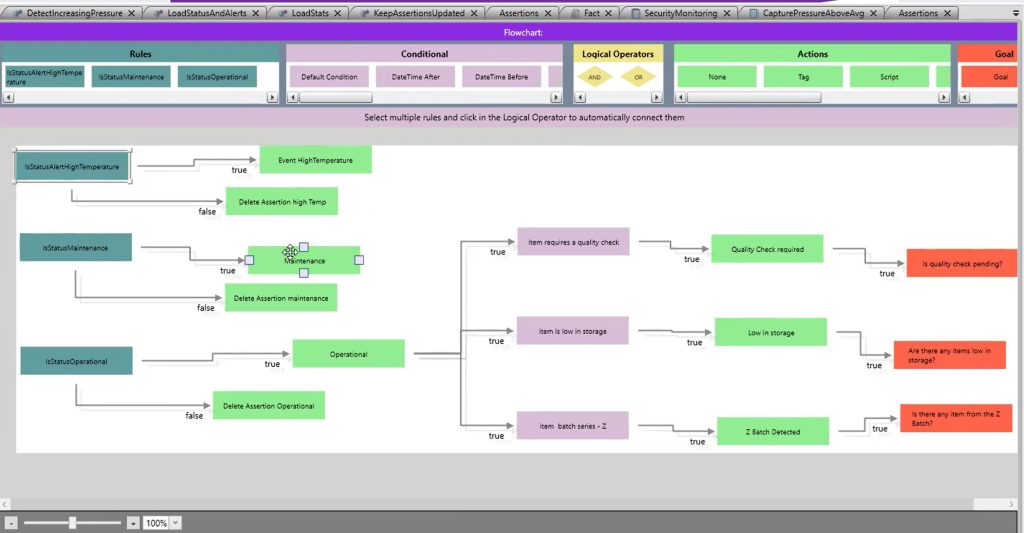

ADISRA SmartView, equipped with an integrated rule-based expert system, enhances hydraulic press operations by applying predefined rules to live sensor data. These rules, grounded in industry expertise, best practices, and safety requirements, transform industrial automation by:

– Triggering alarms as soon as critical operating thresholds are exceeded.

– Initiating corrective actions to prevent component damage and optimize performance.

– Proactively predicting failures to improve reliability and minimize costly downtime.

Example Rule:

IF hydraulic oil temperature exceeds 70°C for more than 2 hours, THEN schedule an inspection for potential cooling system issues.

By implementing rules like this in ADISRA SmartView’s expert system, operators benefit from:

– Real-time monitoring of critical press conditions.

– Early warnings that trigger inspections before damage occurs.

– Proactive scheduling of maintenance to prevent unexpected downtime.

With ADISRA SmartView, hydraulic press operations move beyond simple monitoring to intelligent automation, combining visualization with expert system logic to maximize uptime and extend equipment life.

Experience it for yourself: Download a trial of ADISRA SmartView.

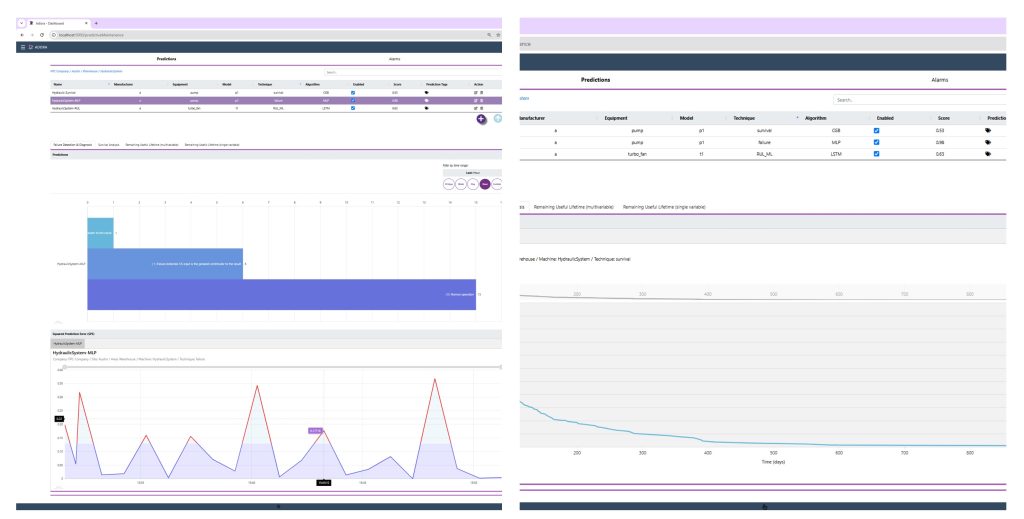

KnowledgeView for Hydraulic Press Predictive Analytics

While ADISRA SmartView handles real-time diagnostics at the edge, KnowledgeView adds a cloud-based layer of intelligence powered by machine learning. Instead of relying solely on fixed rules, KnowledgeView continuously learns from large datasets, uncovering hidden fault signatures that may not trigger an immediate alarm but still indicate emerging issues.

Example Insight:

A hydraulic press pump shows vibration and pressure readings that appear normal individually. However, over time, KnowledgeView

’s ML model identifies that when a specific vibration frequency (220 Hz) coincides with a slight pressure drop (5%) during high-speed cycles, pump seal failures occur within three weeks, with 87% probability.

This kind of insight provides:

– Hidden correlations revealed only through big-data analysis.

– Actionable forecasts that allow seals to be replaced proactively during planned downtime.

– Continuous learning that improves predictive accuracy as more data is collected.

KnowledgeView complements ADISRA SmartView by extending predictive maintenance beyond thresholds and alarms to forecast failures weeks in advance, enabling manufacturers to plan interventions with minimal disruption.

Conclusion: Smarter Maintenance, Greater Reliability

The costs of downtime are too high to ignore. Predictive maintenance, powered by a hybrid of rule-based expert systems and machine learning, allows manufacturers to minimize downtime, extend equipment life, and optimize performance.

With ADISRA SmartView at the edge delivering real-time rule-based expert system diagnostics, and KnowledgeView in the cloud providing adaptive machine learning insights, ADISRA offers manufacturers the best of both worlds: speed, accuracy, adaptability, and foresight.

Take the next step toward smarter predictive maintenance:

Start building intelligent industrial automation solutions today with ADISRA SmartView; download it here.

Have a project in mind? Let us talk. Click this link to request a personalized demonstration with our team.

Need a temporary account for InsightView and KnowledgeView. Request the account at info@adisra.com

If you have a temporary account, you can access InsightView and KnowledgeView here.

Together, we can transform downtime into uptime and predictive maintenance into a true competitive advantage.

See Predictive Maintenance in Action with ADISRA

Want to see how predictive maintenance can transform hydraulic operations? Join us for our next live webinar on September 25th at 9:30 a.m. CDT.

We will demonstrate how ADISRA SmartView’s rule-based expert system delivers real-time predictive maintenance insights at the edge, while KnowledgeView’s machine learning in the cloud uncovers deeper patterns and optimizes long-term performance.

What You will See in the Live Demo:

– How real-time data from a hydraulic system is collected and analyzed in ADISRA SmartView.

– How a local rule-based expert system provides immediate insights to prevent failures at the machine level.

– How ADISRA SmartView and KnowledgeView work together to apply machine learning in the cloud, enabling smarter maintenance scheduling and reducing unplanned downtime.

Event Details:

Date & Time: September 25th, 9:30 a.m. CDT

Format: Live presentation + interactive Q&A

Who Should Attend: Professionals and organizations interested in predictive maintenance, IIoT, and smarter HMI/SCADA applications

Secure your spot today: Register Here

ADISRA®, ADISRA’S logo, InsightView®, and KnowledgeView® are registered trademarks of ADISRA, LLC.

© 2025 ADISRA, LLC. All Rights Reserved.