The Overall Equipment Effectiveness (OEE) software market reached $65.7 billion in 2024 and is expected to grow to $117.67 billion by 2029, underscoring the rapid global shift toward real-time performance monitoring and data-driven manufacturing.

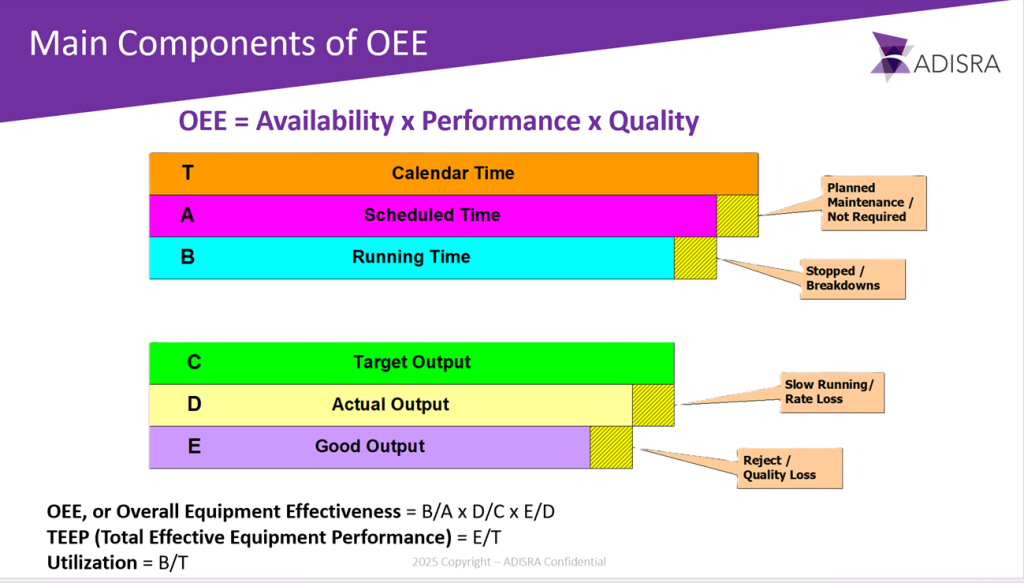

At its core, OEE is a foundational metric that measures how effectively equipment operates relative to its full potential. It is calculated by multiplying three key components:

Availability – The percentage of scheduled time that equipment is running

Performance – How close the equipment is running to its ideal speed

Quality – The proportion of output that meets specification without rework or scrap

Together, these factors provide a clear, data-backed assessment of asset utilization and production efficiency. A higher OEE score reflects stronger equipment performance, more consistent output, and more effective use of available capacity.

Beyond measuring individual machines, OEE offers a unified framework for comparing performance across lines, plants, and even entire manufacturing networks. This makes it a powerful benchmarking tool, both internally and against world-class industry standards.

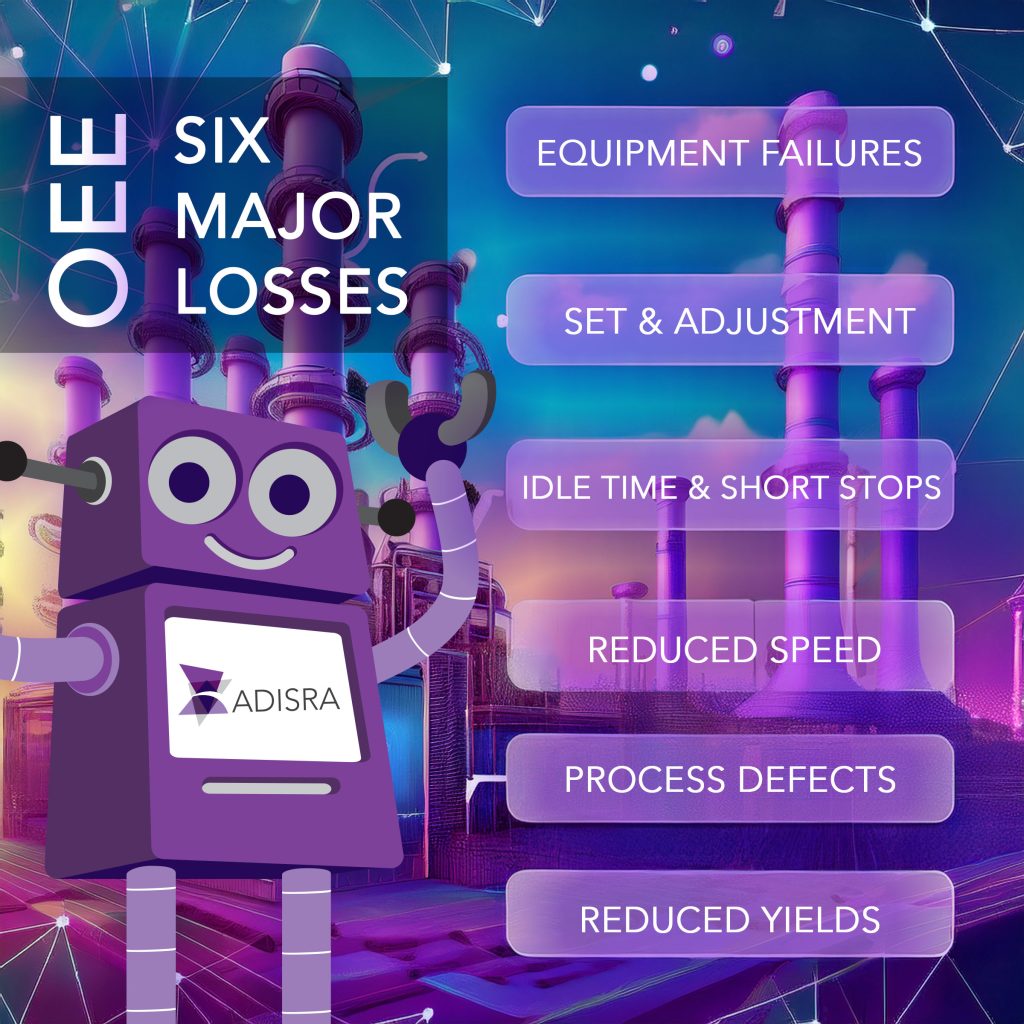

However, improving OEE requires more than monitoring KPIs. True progress comes from identifying and eliminating the Six Major Losses that erode availability, performance, and quality. Addressing these losses not only improves equipment effectiveness but also delivers meaningful business value, as shown in the diagram below.

In today’s hyper-competitive manufacturing environment, every minute of uptime matters. Production lines must operate at peak performance to satisfy customer demand, protect margins, and justify capital investments. OEE remains the industry’s gold standard for measuring operational efficiency, but meaningful improvement demands a strategic, integrated approach that combines proactive planning, skilled teams, and seamless digital execution.

Ultimately, the power of OEE lies in its ability to connect shop-floor performance to strategic outcomes. When used effectively, it becomes a catalyst for reducing waste, increasing throughput, enhancing competitiveness, and building long-term operational excellence.

The dairy sector illustrates this reality exceptionally well. It is an industry where disciplined process control, supported by OEE, can deliver significant improvements in throughput, yield, and profitability. Dairy operations operate under unique pressures: milk is highly perishable, energy and labor costs continue to rise, and retailers expect unwavering quality, sustainability, and competitive pricing. Under these conditions, every unplanned stop, speed loss, or quality deviation has an immediate and measurable impact on yield and margin.

These challenges are compounded by an expanding industry. The global dairy market reached USD 991.5 billion in 2024 and is projected to climb to USD 1.5 trillion by 2033. At the same time, the dairy processing equipment market is expected to grow from USD 14.41 billion in 2025 to USD 25.62 billion by 2034, driven largely by increasing demand for high-value products such as yogurt, cheese, and processed milk, items prized for their convenience and longer shelf life. As plants modernize to meet this demand, optimizing asset utilization becomes essential.

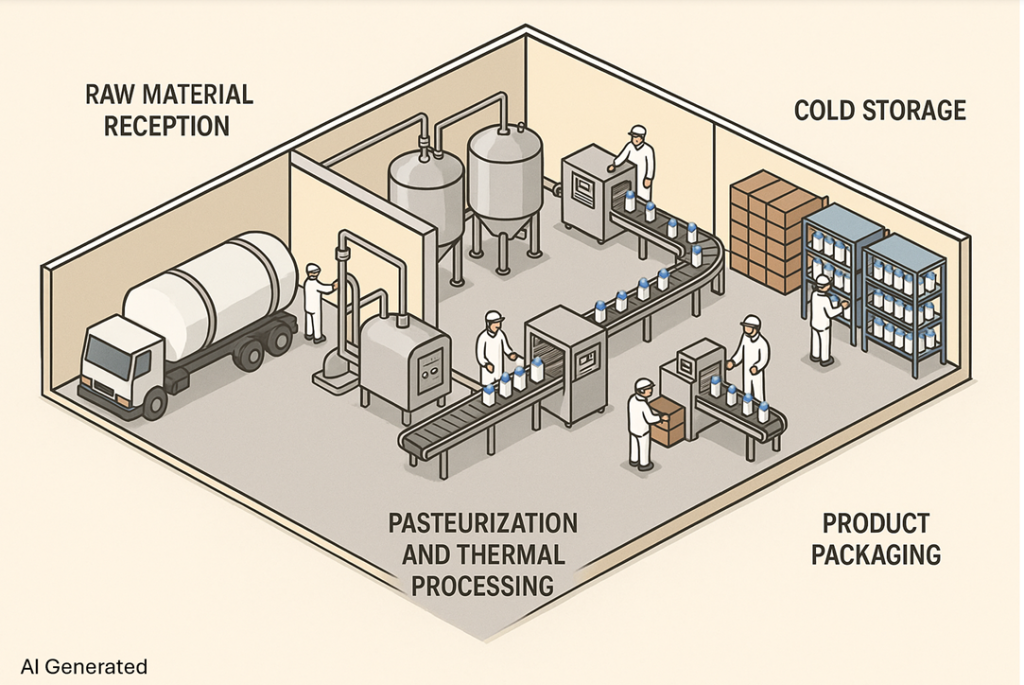

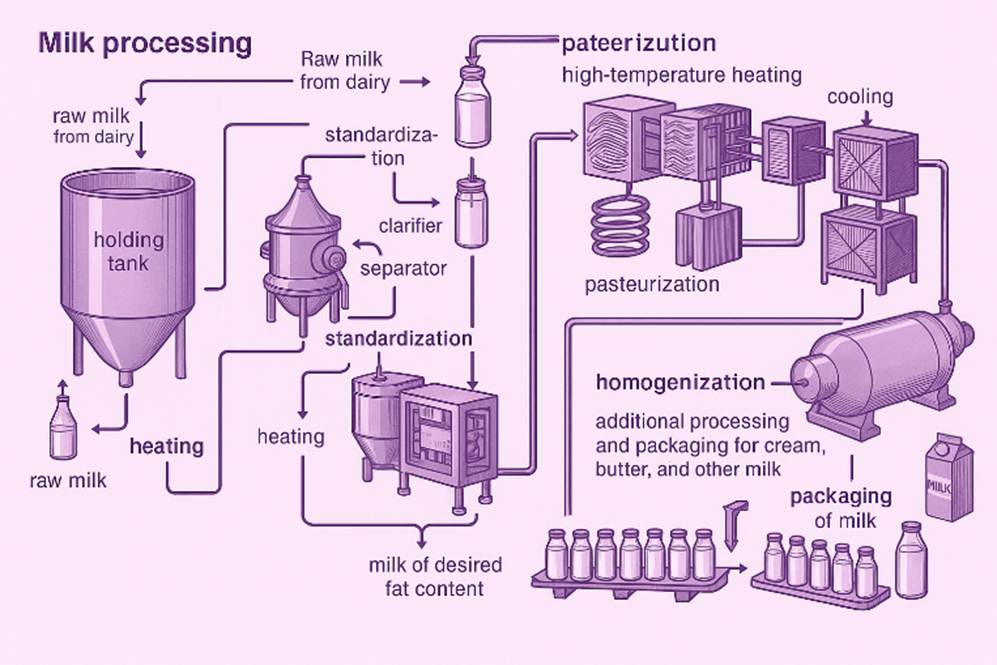

Applying OEE Across the Dairy Production Chain

Dairy manufacturing consists of interconnected processes, each of which benefits from OEE measurement and the identification of the Six Major Losses.

Raw Material Reception

The production cycle in any dairy plant begins with raw material reception, a critical stage where incoming milk is collected, inspected, and prepared for processing. This phase typically involves weighing the tanker, taking quality-control samples, and performing essential tests for temperature, acidity, and potential contaminants such as antibiotic residues.

ADISRA SmartView enhances this stage by delivering real-time monitoring, automated data acquisition, enforced quality-control workflows, and comprehensive data logging for full traceability and regulatory compliance. These capabilities transform what has traditionally been a manual, error-prone process into a more efficient, consistent, and highly controlled operation.

By measuring OEE at the intake stage, dairy processors can optimize tanker unloading times, reduce waiting periods, and maximize utilization of receiving infrastructure. Data-driven scheduling further improves plant flow, ensuring a steady, well-coordinated supply of raw milk and smoother alignment with upstream logistics. With ADISRA SmartView managing this process, plants gain not only improved efficiency but also the reliable traceability required by government and industry regulations.

Pasteurization and Thermal Processing

Pasteurization is one of the most critical thermal processes in a dairy plant. It involves heating milk to a precise temperature for a specific duration to eliminate harmful bacteria and extend shelf life. Because pasteurization directly impacts food safety, government regulations require rigorous record-keeping, including pasteurization charts, processing dates, antibiotic screening results, and detailed Clean-In-Place (CIP) temperature logs.

ADISRA SmartView streamlines and strengthens pasteurization record-keeping by automatically capturing and logging critical parameters, such as temperature, pressure, and flow rates, with high accuracy and secure timestamp integrity. This fully digital approach supports regulatory compliance, improves product traceability, and eliminates the errors and inconsistencies common with manual data entry. For more information on ADISRA SmartView’s compliance capabilities, refer to our previous blog on FDA 21 CFR Part 11 functionality or consult the accompanying whitepaper.

Pasteurization is also a major OEE control point in dairy production. Monitoring performance at this stage helps processors extend runtime between CIP cycles, reduce unplanned downtime, and maintain stable, high-quality thermal treatment, ensuring temperature uniformity and reliable microbial control. Many modern dairies use redundant or dual pasteurization systems to maintain availability even when one line undergoes maintenance.

With its built-in redundancy support and powerful rule-based expert system, ADISRA SmartView further strengthens this process. It can automatically enforce pasteurization rules based on time, temperature, and flow parameters, ensuring strict adherence to standards such as the Pasteurized Milk Ordinance (PMO). These intelligent rules help plants maintain consistent product safety and quality, while preventing deviations before they occur.

Product Packaging

Dairy packaging plays a critical role in protecting perishable products such as milk, cheese, and yogurt, ensuring food safety, maintaining quality, and extending shelf life. Because packaging is often the final step before distribution, any inefficiency directly impacts throughput, waste, and customer satisfaction.

ADISRA SmartView enhances the performance of dairy packaging lines by delivering real-time monitoring, precise control, and automated data logging across all critical packaging activities. With ADISRA SmartView, operators can remotely manage equipment, automatically adjust to maintain consistent filling and sealing, and quickly respond to issues before they escalate, reducing downtime and preventing product loss. Key benefits include improved traceability through comprehensive data capture, automated quality checks such as lot and date-code verification, and faster, more consistent changeovers supported by built-in recipe management.

Packaging is also one of the most impactful areas for improving OEE. Continuous monitoring can uncover the root causes of frequent micro-stops, highlight opportunities to shorten SKU changeovers, and enhance seal integrity, label accuracy, and overall packaging quality. OEE insights support more effective staffing decisions, reveal where automation investments will have the greatest return, and help benchmark the performance of different packaging lines.

ADISRA SmartView supports all these stages by delivering real-time visibility, automated control, and a rich set of analytics that help operators detect issues early, respond quickly, and maintain consistent packaging performance.

Across the broader packaging operation, OEE enables teams to identify delays caused by cleaning and sterilization, compare line efficiency, and understand how maintenance schedules, operator practices, and product mix influence throughput. It also helps highlight imbalances, such as overloading one line while others remain underutilized, creating a stronger foundation for production planning and smart capital allocation.

OEE and the Six Major Losses in Dairy Processing

The Six Major Losses provide a framework for problem-solving at every level of the dairy operation.

Machine Level (Example: Yogurt Packaging Line)

– Availability:

Failures caused by faulty level or temperature sensors, film-feed jams, intermittent actuator faults, or interruptions during film or lid-stock changeovers. These events directly reduce runtime by triggering unexpected stops or slow restarts.

– Performance:

Throughput reduction resulting from residue buildup on filling nozzles or sealing heads, micro-stoppages due to cup misalignment at the infeed, or minor disturbances in indexing accuracy. These conditions cause the machine to run below its nominal cycle rate.

– Quality:

Nonconforming units are produced due to inadequate seal integrity, inconsistent fill volumes, improper temperature control, or scrap generated during equipment startup, warm-up, or ramp-up when process parameters have not yet stabilized.

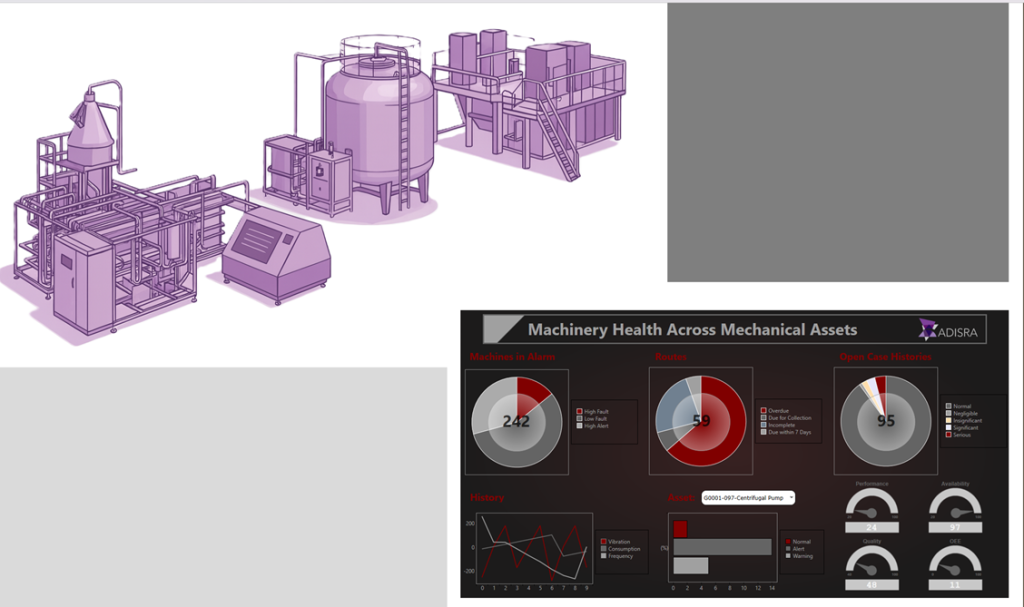

ADISRA SmartView enhances OEE at the machine level by providing deterministic real-time data acquisition, high-resolution visualization of machine states, and contextualized event tracking directly at the HMI/SCADA layer. Operators gain immediate insight into availability losses, cycle-time deviations, and quality-related faults as they occur.

ADISRA SmartView’s integrated rule-based expert system further strengthens machine-level performance by automatically interpreting machine data, diagnosing root causes, and predicting emerging failure modes. The system can issue targeted recommendations, such as when to clean residue buildup, recalibrate sensors, or adjust infeed timing, reducing unplanned downtime, stabilizing machine speed, and improving first-pass quality.

Plant-Wide Level (All Dairy Lines: Milk, Yogurt, Cheese, UHT)

Aggregating OEE data at the plant level provides a comprehensive understanding of where performance losses are concentrated. Trends such as extended changeover times across multiple lines, repeated failures within specific equipment families, or widespread quality deviations allow engineering and operations teams to prioritize improvement efforts and deploy resources where they will have the greatest operational impact.

ADISRA SmartView fully supports this plant-wide strategy by acting as a centralized platform for monitoring, controlling, and optimizing all production areas, including milk, yogurt, cheese, and Ultra-High Temperature (UHT) processing lines. By consolidating real-time data acquisition, supervisory control, analytics, and traceability into a single, unified environment, ADISRA SmartView enhances operational consistency, strengthens quality assurance, reduces human error, and lowers overall operating costs.

ADISRA SmartView’s capability to scale across large-screen displays also makes it ideally suited for modern Andon systems. In dairy facilities, Andon boards are essential lean manufacturing tools that provide immediate visual notifications of quality issues, process deviations, or equipment alarms. ADISRA SmartView digitizes this functionality by replacing traditional cords, lights, and physical indicators with dynamic, real-time alerts, interactive dashboards, and high-visibility status screens that improve operator awareness and accelerate response times.

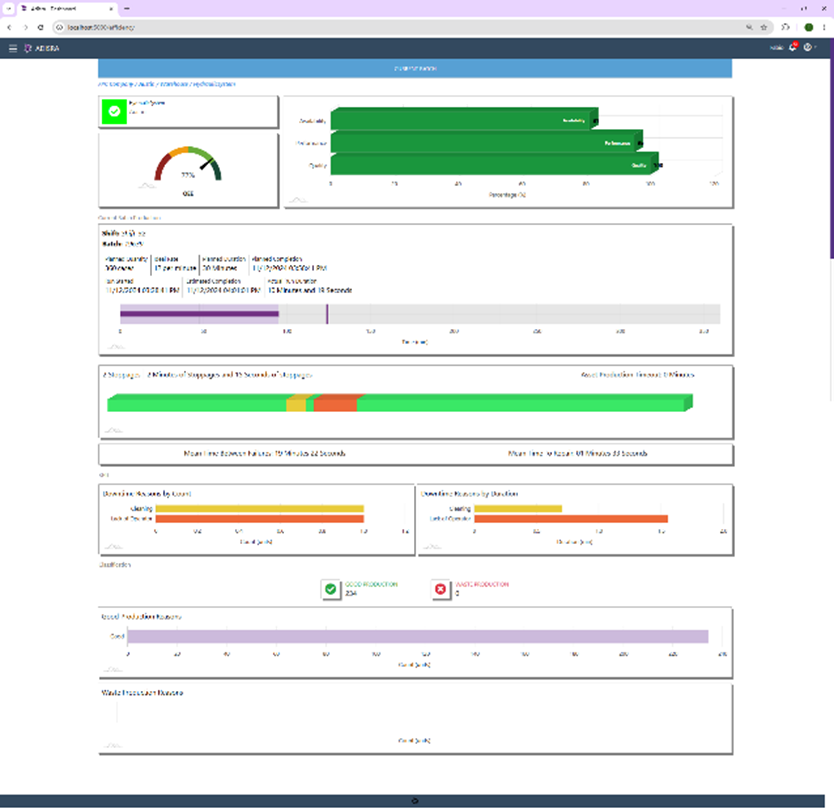

Multi-Plant, Cloud-Based OEE

For dairy companies operating multiple facilities, cloud-based OEE delivers a unified, real-time view of performance across all plants. This consolidated perspective enables benchmarking, identification of systemic issues, and sharing of best practices that may not be visible when sites operate independently. Management gains a centralized dashboard to monitor OEE and the Six Major Losses across different lines, products, and regions—supporting continuous improvement and data-driven strategic planning at scale.

ADISRA InsightView, built on AWS or Azure, transforms raw production data into actionable intelligence. Plant managers can identify bottlenecks, compare shift and line performance, and evaluate OEE across sites to standardize operating procedures. InsightView provides drill-down visibility into the Six Major Losses—equipment failures, setup losses, idling, speed losses, defects, and startup losses—helping teams target the root causes of efficiency loss.

Key performance metrics include:

– Opportunity Gap – The difference between potential and actual output.

– Capacity Utilization – How effectively each line uses its available capacity.

– Cycle Time & Efficiency – Measures of process rate and value-added time.

– Throughput – Total product output over time.

– Planned Maintenance Percentage – Balance of scheduled vs. emergency maintenance.

Using these insights, dairy manufacturers can improve productivity, reduce waste, and optimize asset utilization, ensuring consistent, high-quality performance across all facilities.

Additional metrics commonly used when comparing dairy plants include:

– Operational efficiency: capacity utilization, energy consumption, waste reduction.

– Quality control: milk quality, product consistency.

– Supply chain metrics: milk transportation efficiency, storage losses.

– Resource management: water usage, feed efficiency.

– Energy Performance Index (EPI): a 1–100 score that benchmarks energy efficiency against industry standards, where 50 represents the median, and higher scores indicate superior energy performance.

Conclusion: The Power of a Hybrid OEE Strategy in Dairy Manufacturing

In the modern dairy industry, efficiency, consistency, and traceability are no longer competitive advantages; they are fundamental expectations. A hybrid OEE approach delivers the visibility and control needed at every level of production.

At the machine level, operators gain immediate insight into availability losses, speed fluctuations, and quality deviations, enabling rapid intervention and reducing unplanned downtime. At the plant level, supervisors can compare line performance, identify systemic bottlenecks, optimize changeovers, and balance workloads across milk, yogurt, cheese, and UHT lines. And at the multi-plant level, cloud-based OEE provides executives with a unified view of performance across all facilities, driving standardization, benchmarking, and continuous improvement at scale.

Together, this layered approach equips dairy manufacturers to increase throughput, reduce waste, improve product quality, and strengthen profitability, all while meeting strict food safety and regulatory requirements (see FDA CFR Part 11 blog here).

ADISRA SmartView delivers machine- and plant-level real-time control for precision operations on the plant floor, while ADISRA InsightView unlocks enterprise-wide analytics and cloud-driven intelligence across multiple facilities. Combined, they create an end-to-end OEE ecosystem that helps teams make better decisions, faster.

Call to Action

If you are ready to modernize your dairy or food operations, eliminate hidden losses, and build a smarter, more resilient production environment, now is the time to embrace a hybrid OEE strategy.

Contact us today to schedule a demonstration of ADISRA SmartView and InsightView, and see how our integrated OEE platform can transform performance on your processing lines, one machine, one plant, and one enterprise at a time.

You can also download a copy of ADISRA SmartView here to begin seeing the advantages it brings to food processing plants.

You can request a demo account of InsightView by sending a message to info@adisra.com

Upcoming Event

Webinar Invitation: “From the Shop Floor to the Cloud: Maximizing OEE Everywhere” on 9 December 2025 – 9:30 a.m. CST; 10:30 a.m. CCOT; 3:30p.m. UTC/GMGMT; 4:30.m. CET; 5:30 p.m. EET; 11:30 a.m. (10 Dec) MYT;

Manufacturers today face a critical challenge: achieving complete visibility into production efficiency, whether at the machine level, within a single facility, or across an entire network of dairy plants.

Join us for our upcoming webinar, “From the Shop Floor to the Cloud: Maximizing OEE Everywhere,” where we explore how to optimize OEE both on-premise and in the cloud.

This session will demonstrate how ADISRA SmartView delivers real-time OEE precision at the machine and plant level, while ADISRA InsightView provides multi-site visibility, benchmarking, and cloud-driven analytics for strategic, enterprise-wide decision-making.

Whether you manage one facility or multiple plants across regions, you will learn how to:

- Measure and improve performance in real time at the machine, line, and plant level

- Aggregate OEE data across multiple sites for deeper insights and cross-plant benchmarking

- Empower teams at every level with unified visibility, alerts, and collaboration tools

- Accelerate improvement cycles using cloud analytics, dashboards, and predictive insights

Do not miss this opportunity to discover how modern OEE solutions bridge the gap between operations and strategy, helping you increase efficiency, reduce downtime, enhance quality, and stay competitive in a connected manufacturing world.

You can register for the webinar by clicking here.

ADISRA®, ADISRA’S logo, InsightView®, and KnowledgeView® are registered trademarks of ADISRA, LLC.

© 2025 ADISRA, LLC. All Rights Reserved.