As we enter 2026, manufacturing and industrial leaders are navigating a landscape shaped by converging forces: accelerated adoption of artificial intelligence, ongoing geopolitical uncertainty, increasing sustainability requirements, and renewed focus on industrial policy and supply-chain resilience. These pressures are not theoretical; they are directly influencing how plants are designed, operated, and modernized.

The past few years have delivered remarkable advances in industrial automation. But the most meaningful shift is not the technology itself; it is how automation is becoming more practical, accessible, and deployable at scale. What was once limited to highly customized, resource-intensive projects is now available to a much broader range of manufacturers, operators, and system integrators.

At the same time, labor constraints persist, production demands continue to increase, and operations are under pressure to respond faster while supporting greater variability and customization. Automation is no longer a “nice to have.” Its value is already proven across factories, warehouses, laboratories, utilities, agriculture, and critical infrastructure worldwide. The challenge in 2026 is no longer whether to automate, but how to deliver measurable value quickly and reliably across distributed operations.

This is where ADISRA’s approach comes into focus. Through platforms such as ADISRA SmartView, InsightView, and KnowledgeView, ADISRA enables organizations to move beyond visualization toward intelligent, data-driven operations, combining real-time edge intelligence, cloud-based analytics, and practical AI without unnecessary complexity.

A single breakthrough or standalone solution does not define the automation trends shaping 2026. Instead, they reflect the convergence of AI, edge computing, IoT, data integration, and cybersecurity, working together to deliver scalable, secure, and actionable intelligence. The following predictions highlight the technologies and architectural shifts ADISRA expects to see in 2026 and how they translate into real operational value across industries and company sizes.

Prediction #1: AI Will Redefine Industrial Automation and Operator Interfaces in 2026

Artificial Intelligence is no longer an emerging concept in industrial automation—it is becoming foundational. As we enter 2026, AI continues to reshape how operators interact with systems, how decisions are made, and how value is extracted from industrial data. Two areas driving this transformation are AI agents and Large Language Models (LLMs), supported by rapid advances in predictive analytics, IoT analytics, and edge intelligence.

AI Agents: From Concept to Autonomous Execution

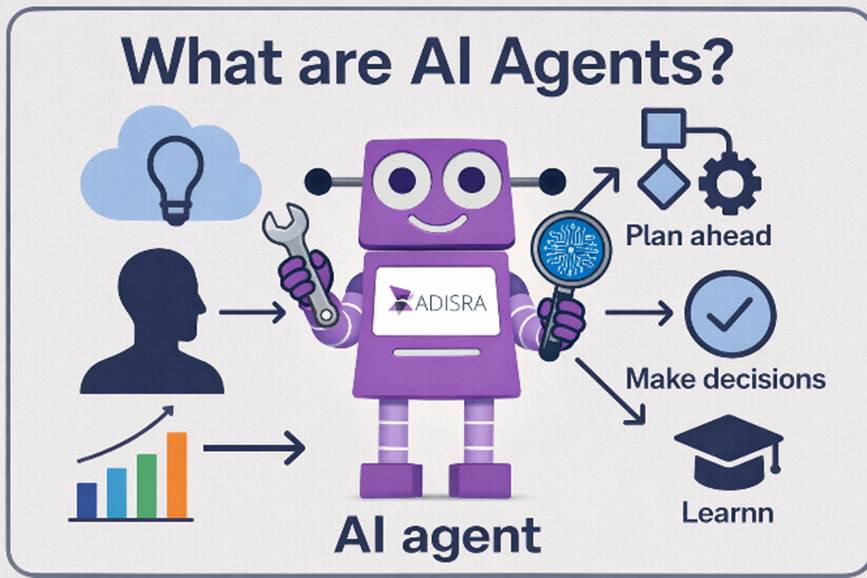

After gaining credibility as an enterprise technology in 2024, AI agents moved swiftly from hype to evaluation in 2025 and are now transitioning into real-world adoption. An AI agent is an intelligent software system capable of sensing its environment, reasoning about conditions, planning actions, and acting autonomously to achieve defined objectives.

Key characteristics of AI agents include:

Autonomy – AI agents operate independently, making decisions and taking action without constant human oversight. Decisions may be driven by predefined rules, learned behaviors, or real-time data analysis.

Learning capability – AI agents improve over time by learning from outcomes. This learning can be achieved through machine learning or reinforcement learning, in which agents adjust their behavior based on rewards or penalties.

Goal-oriented behavior – AI agents are designed to achieve specific objectives, breaking complex goals into manageable sub-goals. Human operators can intervene at any stage to provide feedback or redirect outcomes.

Environmental perception – AI agents ingest and analyze data from multiple sources to identify trends, anomalies, and optimization opportunities.

In industrial settings, AI agents are increasingly positioned to support operators by continuously monitoring systems, identifying issues early, and recommending or executing corrective actions.

Large Language Models: A New Interface to Industrial Systems

In parallel, generative AI powered by Large Language Models has matured rapidly. LLMs are deep-learning systems built on transformer architectures and trained on massive datasets to understand and generate human language. They enable tasks such as summarization, reasoning, translation, and natural language interaction with software systems.

At their core, LLMs are large statistical prediction engines that generate text by predicting the most likely next word in a sequence. What makes them transformative is their ability to capture context, nuance, and intent, something traditional rule-based or keyword-driven systems cannot do at scale.

For industrial automation, LLMs represent a fundamental shift in how humans interact with technology. Instead of navigating complex menus or scripts, operators can increasingly interact with systems using natural language, making advanced analytics and diagnostics more accessible to a broader workforce.

AI in Industrial Automation: What Continues to Evolve in 2026

As AI adoption accelerates, several areas will continue to shape industrial automation software:

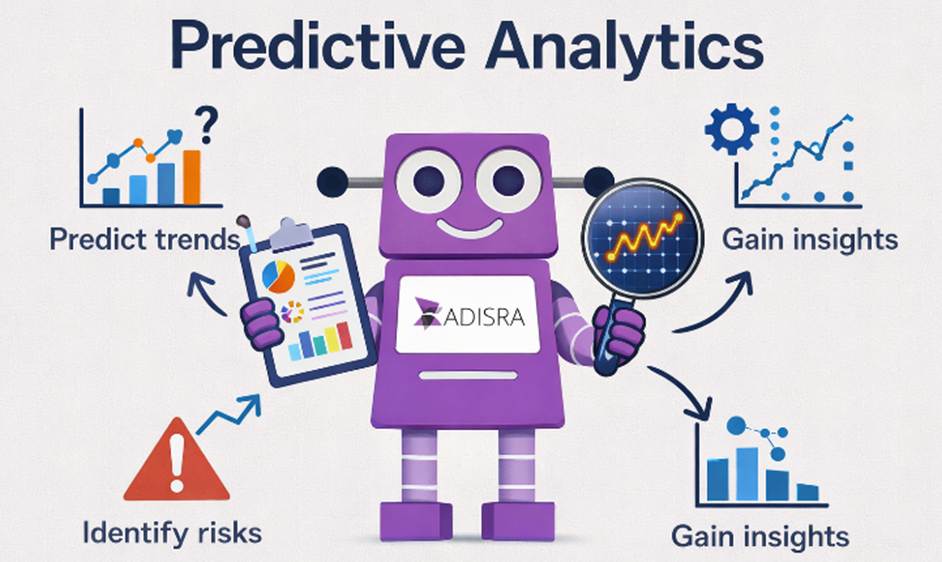

Predictive analytics

Traditional reactive approaches are no longer sufficient for modern, complex production environments. Predictive analytics enables manufacturers to anticipate equipment failures, optimize production schedules, improve product quality, and strengthen supply chains. By combining historical data, statistical models, and machine learning, predictive analytics helps organizations move from reactive to proactive operations.

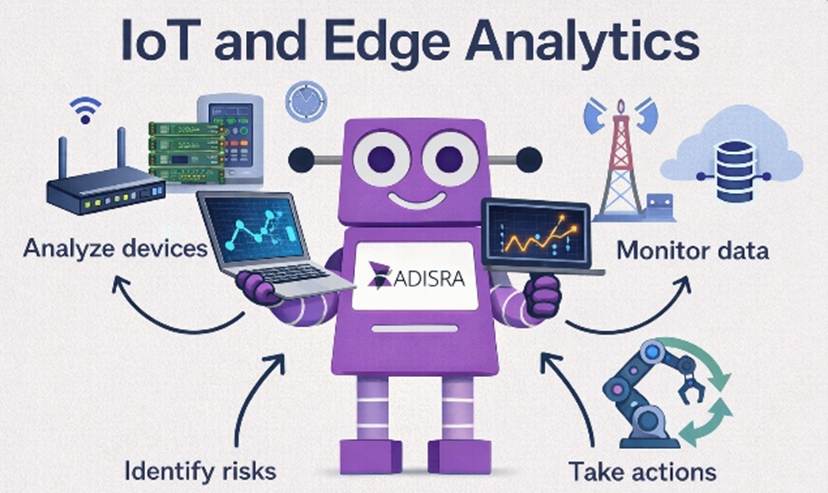

IoT and edge analytics

Industrial AI investment is growing rapidly, with IoT analytics playing a central role. Connected devices generate enormous volumes of heterogeneous data every day. The actual value of IoT lies in transforming this raw data into actionable insights.

Edge analytics, processing data at or near its source, continues to gain traction in 2026, enabling faster decisions, reduced latency, and improved reliability. Applications range from manufacturing and energy to smart agriculture, where real-time analytics optimize irrigation, monitor soil conditions, and improve crop yields.

From Rules to Learning: The ADISRA Approach

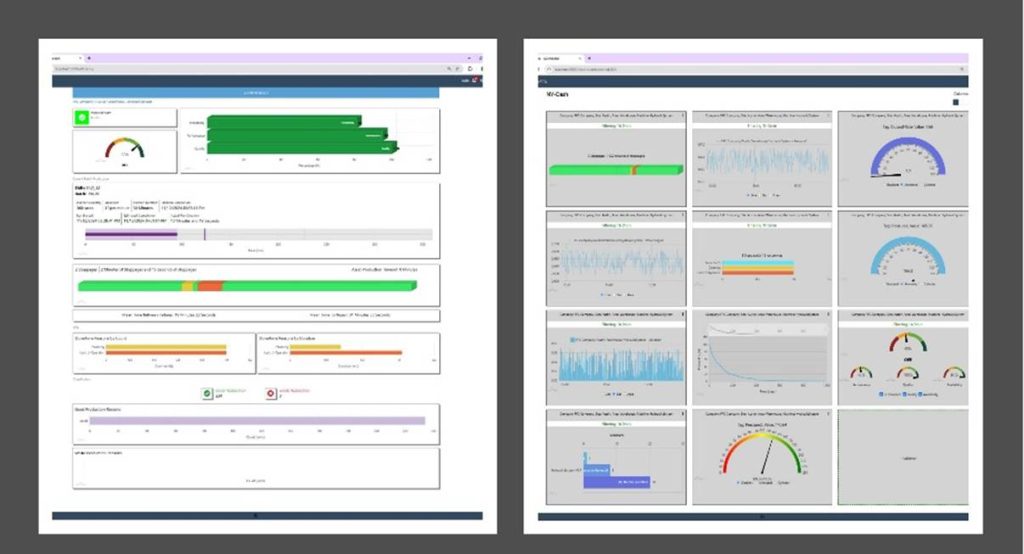

ADISRA SmartView, equipped with a built-in rule-based expert system, provides a practical and intuitive entry point into industrial analytics. Users can focus on defining rules, modeling expert knowledge, and driving outcomes without the complexity typically associated with advanced analytics platforms. Predictive maintenance can be achieved through expert system logic that maximizes uptime and extends equipment life.

Beyond predictive maintenance, ADISRA SmartView delivers real-time analytics at the edge, supporting applications such as immediate operational insights, anomaly detection, security monitoring, and real-time standards compliance.

While ADISRA SmartView handles deterministic, real-time diagnostics at the edge, KnowledgeView adds a cloud-based layer of intelligence powered by machine learning. KnowledgeView continuously learns from large datasets, uncovering subtle fault patterns that may not trigger immediate alarms but signal emerging issues.

Looking Ahead

In 2026, industrial automation software will no longer simply display data; it will interpret it, contextualize it, and recommend actions. AI will reduce operator workload through continuous real-time monitoring, enhance decision quality, and enable more resilient and adaptive industrial operations.

Ready to explore ADISRA SmartView? Download and test it here:

Need a temporary KnowledgeView account? Request access at: info@adisra.com

Prediction #2: Edge, IoT, and AI Will Converge to Power Real-Time Industrial Intelligence

In 2026, the convergence of Edge Computing and the Internet of Things (IoT) will become a cornerstone of industrial automation strategies. Rather than sending all data to centralized cloud platforms, organizations are increasingly processing data locally, at or near its source, to enable faster decisions, lower latency, reduced bandwidth usage, and improved security.

Edge computing is a distributed computing model that moves applications and analytics closer to data-generating devices such as sensors, cameras, and industrial equipment. As connected devices proliferate, accelerated by 5G and high-speed networks, this approach enables real-time insights that cloud-only architectures cannot deliver.

IoT refers to networks of physical devices embedded with sensors and software that continuously generate large volumes of operational data. In industrial environments, this includes assets such as turbines, pumps, motors, production lines, and mobile equipment. When combined with edge computing, IoT data can be filtered, analyzed, and acted upon immediately, with only critical insights or summaries sent to the cloud for long-term analysis and storage.

Industrial IoT and Edge AI

Industrial IoT (IIoT) extends IoT capabilities to complex and high-value manufacturing assets. Sensors are increasingly deployed not only on primary equipment, but also on vulnerable or failure-prone components, helping engineers identify root causes, performance bottlenecks, and early signs of degradation.

The next evolution is Edge AI, where intelligence is embedded directly into edge devices. Machine learning models running at the edge analyze continuous data streams in real time, enabling faster responses and greater system autonomy. This approach supports applications such as predictive maintenance, quality inspection, anomaly detection, and adaptive process control—without relying on constant cloud connectivity.

According to MarketsandMarkets, the global industrial edge market is expected to grow from USD 21.19 billion in 2025 to USD 44.75 billion by 2030, driven by rapid digitization, increased IoT adoption, and the demand for real-time, on-site data processing.

From Edge Intelligence to Cloud Collaboration

On the edge, intelligence is becoming more advanced, with AI integrated directly into hardware and runtime platforms. ADISRA SmartView supports this transition by running headless on both Windows and Linux platforms, enabling real-time analytics and AI-driven decision-making directly at the edge.

As data models grow more complex, industrial architectures are increasingly hybrid. Real-time AI operates close to the data source. At the same time, cloud-based platforms, augmented with machine learning and Large Language Models, analyze larger historical datasets to uncover deeper patterns and long-term insights. This collaborative edge-to-cloud approach delivers the best of both worlds: immediate intelligence at the edge and strategic learning in the cloud.

In 2026, the integration of Edge, IoT, and AI will shift industrial automation from reactive monitoring to proactive, intelligent operations, laying the foundation for faster decisions, higher resilience, and more autonomous systems.

Prediction #3: Data Integration Becomes the Backbone of AI-Driven Industrial Systems

2026 marks a pivotal shift in how organizations approach data integration. What was once viewed as a technical requirement is now recognized as a strategic foundation for AI, automation, and real-time decision-making.

The data integration market is growing rapidly as enterprise data environments become more complex. According to MarketsandMarkets, the global data integration market reached approximately USD 17.1 billion in 2025 and is projected to exceed USD 47.6 billion by 2034. Complementing this outlook, Precedence Research forecasts growth from USD 17.58 billion in 2025 to USD 33.24 billion by 2030, underscoring strong and sustained market momentum.

This complexity stems from the rise of multi-cloud, hybrid cloud, edge, and on-premises infrastructures, all of which require seamless, scalable data connectivity. Organizations have come to realize that integrating data is the only realistic way to unlock its full value. When data is unified, businesses can derive accurate, timely insights and act with confidence.

Why Data Integration Is Accelerating

Several forces are driving this shift:

– AI-ready data infrastructure requirements, where high-quality, contextual data is essential

– Multi-cloud and hybrid strategies that fragment data across environments

– Agentic AI systems that require real-time access to trusted data

– Government initiatives such as the U.S. Federal Data Strategy, India’s National Data Governance Framework, and the EU Data Act, which emphasize interoperability and accessibility

As a result, data integration has evolved into the backbone of modern AI systems, enabling autonomous decision-making and faster responses to changing market conditions.

The Persistent Challenge: Data Silos

Despite increased investment, data silos remain one of the most significant barriers to digital transformation. Many organizations face a paradox: while accelerating the adoption of generative AI and automation, disconnected data initiatives unintentionally create new silos rather than eliminate old ones.

Modern data integration platforms address this challenge through:

– Unified data access that connects disparate systems into a single view

– Real-time synchronization to keep data consistent across platforms

– API-led connectivity that makes data available to applications and AI agents

– Data virtualization that enables access without moving or duplicating data

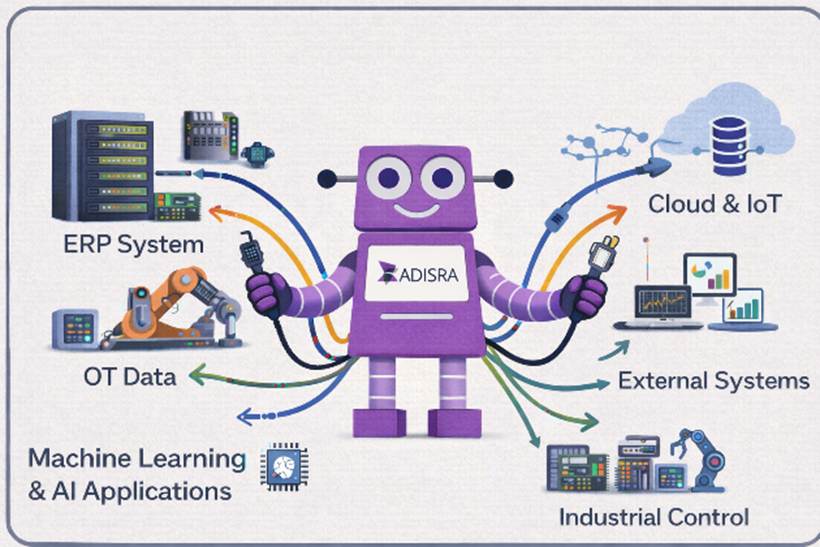

What This Means for Industrial Automation

In industrial environments, HMI, SCADA, and PLC systems are no longer treated as isolated components. Platforms such as ADISRA SmartView, with built-in support for industrial and IT protocols and straightforward database connectivity, provide a simple and effective way to consolidate data from disparate machines and systems.

The 2026 reality: SCADA systems are evolving from passive polling engines into real-time data publishers, feeding analytics platforms, AI agents, and enterprise systems with contextualized operational data.

Data integration is no longer optional; it is the connective tissue that enables intelligent, adaptive, and AI-driven industrial operations.

Prediction #4: Cybersecurity Becomes a Core Pillar of Operational Resilience

As we enter 2026, it would be remiss not to highlight cybersecurity as a defining challenge for both industrial and enterprise systems. The threat landscape is rapidly evolving into a far more complex battlefield, marked by increasingly sophisticated attack vectors and the rise of agentic AI capable of autonomous decision-making. In this environment, cybersecurity is no longer just an IT concern; it is a fundamental component of organizational resilience, requiring proactive strategies that span IT, OT, edge, and cloud infrastructures.

Market forecasts reinforce the urgency of this shift. According to Future Market Insights, the industrial cybersecurity market is valued at approximately USD 26.0 billion in 2025 and is projected to more than double, reaching USD 55.1 billion by 2035. Similarly, Global Market Insights estimates the market at USD 21.7 billion in 2025, with growth accelerating from USD 23.3 billion in 2026 to over USD 51.1 billion by 2035. Together, these forecasts highlight sustained, long-term investment in securing industrial and operational technology environments.

By 2026, industrial cybersecurity will be defined by the escalation of AI-driven attacks and an urgent shift toward integrated, resilient security architectures built directly into OT networks. Organizations will move away from fragmented IoT and OT security tools in favor of unified cybersecurity platforms that provide a single, real-time view across IT, OT, and IoT environments, spanning the edge, plant floor, and cloud.

Adversaries are already leveraging AI to accelerate vulnerability discovery, automate attacks, conduct sophisticated social engineering, and deploy self-evolving malware that can evade traditional, perimeter-based defenses. In response, defenders are increasingly deploying AI agents and automation within Security Operations Centers to enable machine-speed detection, triage, and response capabilities that are becoming essential as industrial environments grow more interconnected and digitally dependent. This shift is further accelerated by escalating ransomware attacks on operational technology, mounting financial impact, rising global data breach costs, cybercrime projected to reach USD 10.5 trillion annually, and intensifying regulatory pressure.

Governments and regulators are moving from guidance to enforcement, including mandates such as the EU’s NIS2 Directive and directives from CISA that require secure-by-design engineering, Zero Trust adoption in OT environments, and greater executive accountability. At the same time, nation-state actors and cybercriminal groups are increasingly targeting critical infrastructure such as energy, manufacturing, transportation, and water systems while exploiting software and service supply-chain vulnerabilities to scale attacks downstream. Together, these forces are driving rapid growth in the industrial cybersecurity market and fundamentally reshaping industrial architecture, making cybersecurity a core operational requirement alongside safety, reliability, and uptime.

Conclusion: Turning Predictions into Action in 2026

As these predictions make clear, 2026 is not about a single technology leap; it is about architectural maturity. AI, edge computing, IoT, data integration, and cybersecurity are converging into cohesive industrial systems that deliver measurable value faster and at greater scale. The winners will not be those who chase every new tool, but those who build secure, intelligent, and adaptable foundations that can evolve with the pace of change.

Industrial automation is moving beyond visualization and isolated analytics. Systems must now interpret data, contextualize conditions, and recommend or execute actions, all while operating reliably across distributed environments and under increasing regulatory and security pressure.

This is precisely where ADISRA is focused. Through ADISRA SmartView, InsightView, and KnowledgeView, ADISRA enables organizations to adopt AI and advanced analytics in practice, starting with rule-based intelligence at the edge and extending to cloud-based learning and optimization when and where it makes sense.

In 2026, success will not be defined by how much data you collect, but by how quickly you can turn insight into action, safely and at scale.

The future of industrial automation is intelligent, connected, and resilient.

ADISRA is ready to help you build it.

Download and test ADISRA SmartView here:

Request a temporary account for InsightView and KnowledgeView access by sending an email to: info@adisra.com

Have a project in mind? Let’s connect. Click here to schedule a personalized demonstration.

ADISRA®, ADISRA’s logo, InsightView®, and KnowledgeView® are registered trademarks of ADISRA, LLC.

Copyright

© 2026 ADISRA, LLC. All Rights Reserved.