Student Projects

Welcome to Our Student Project Showcase

This page highlights inspiring, hands-on work created by the next generation of engineers,

developers, and industrial automation professionals. Using ADISRA SmartView, students bring real-

world HMI/SCADA concepts to life through thoughtful design and practical application.

These projects showcase far more than technical skill; they reflect curiosity, creativity, and the ability

to transform ideas into fully functioning industrial solutions. We are proud to share these

applications as examples of what is possible, and we encourage you to connect with these talented

students as they continue to grow in their careers.

Battery monitoring through Human Machine

Interface (HMI) and Supervisory Control and

Data Acquisition (SCADA) systems is rapidly

expanding, driven by digital transformation,

renewable energy growth, and the increasing

demand for resilient power in data centers.

Key industry trends include the use of AI and

machine learning for predictive maintenance,

cloud and mobile accessibility, IIoT

integration, and a heightened focus on

operational reliability.

This ADISRA SmartView application provides

real-time monitoring and statistical analysis

of batteries and other power sources. It

visualizes critical parameters such as voltage,

current, charge levels, and overall system

health, showcasing how ADISRA SmartView

can transform raw data into actionable

insights.

Once you download the application, the

username and password are:

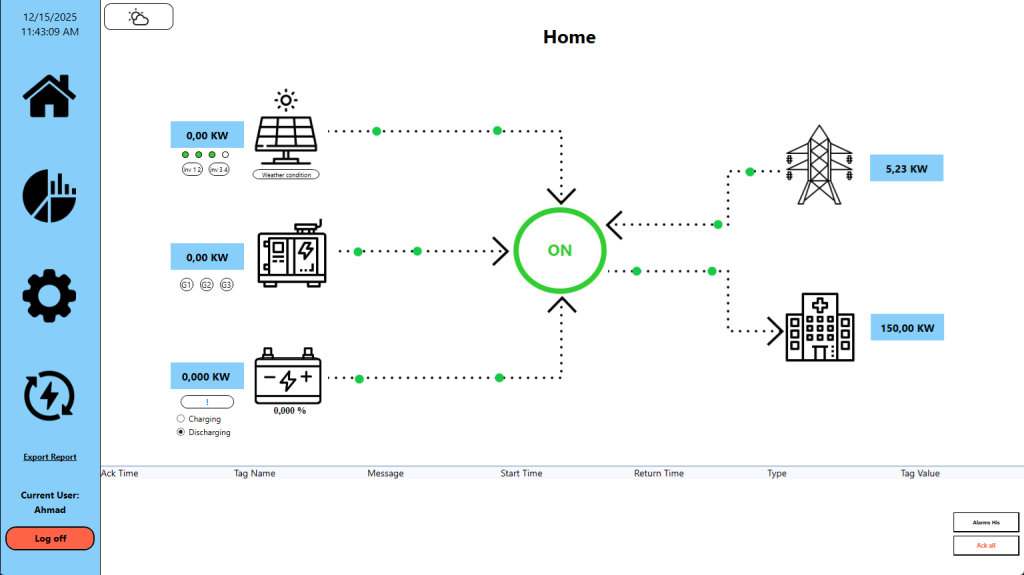

This ADISRA SmartView project is designed to

monitor and control a hybrid energy

infrastructure that includes generators, solar

panels, and fuel tanks—components

commonly found in modern industrial and

remote power systems. As industries

accelerate their transition to cleaner, more

resilient energy strategies, hybrid diesel-solar

systems are becoming increasingly essential

for reducing fuel consumption, improving

uptime, and lowering operational costs.

The application provides real-time visibility

into critical energy assets, tracking key

parameters such as generator performance,

solar production, fuel levels, system load,

alarms, and overall energy efficiency.

The patient monitoring device market is

expanding rapidly, fueled by technological

innovation and the increasing need for

continuous, real-time surveillance that meets

stringent regulatory and interoperability

standards.

A hospital or veterinary supervision screen

built with ADISRA SmartView provides a clear,

intuitive graphical interface that displays real-

time data from sensor tags to track patient or

animal status. Designed for operational

clarity, these screens help caregivers make

informed decisions, respond quickly to

changes, and manage alarms with confidence.

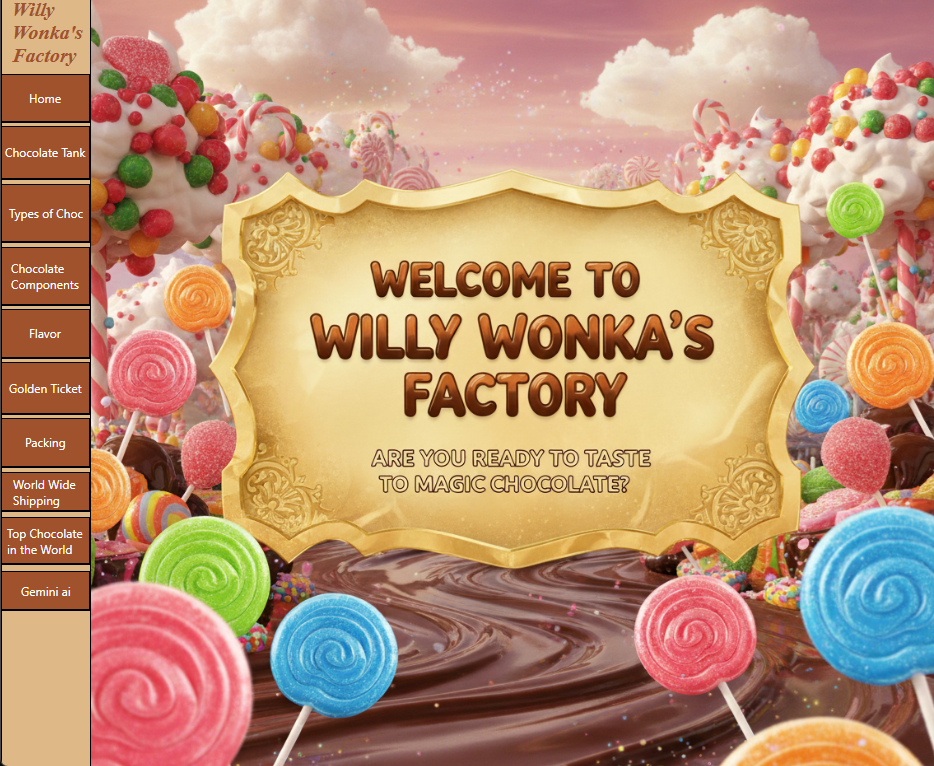

The chocolate confectionery industry is facing

unprecedented challenges, from climate-

driven supply shortages and extreme weather

to widespread crop diseases, aging cacao

trees, and decades of underinvestment in

farms, especially in major producing regions

like Ghana and the Ivory Coast. With shrinking

margins and rising uncertainty, efficiency

across the supply chain has never been more

essential.

This project showcases an ADISRA SmartView

application designed to manage a fictional

Willy Wonka–style chocolate factory,

providing end-to-end visibility from

production through distribution. The system

demonstrates how modern HMI/SCADA tools

can streamline operations, improve decision-

making, and even help identify potential

supply-chain partners. It’s a fun, imaginative

way to explore real-world industrial

automation challenges within a whimsical

chocolate-factory setting.

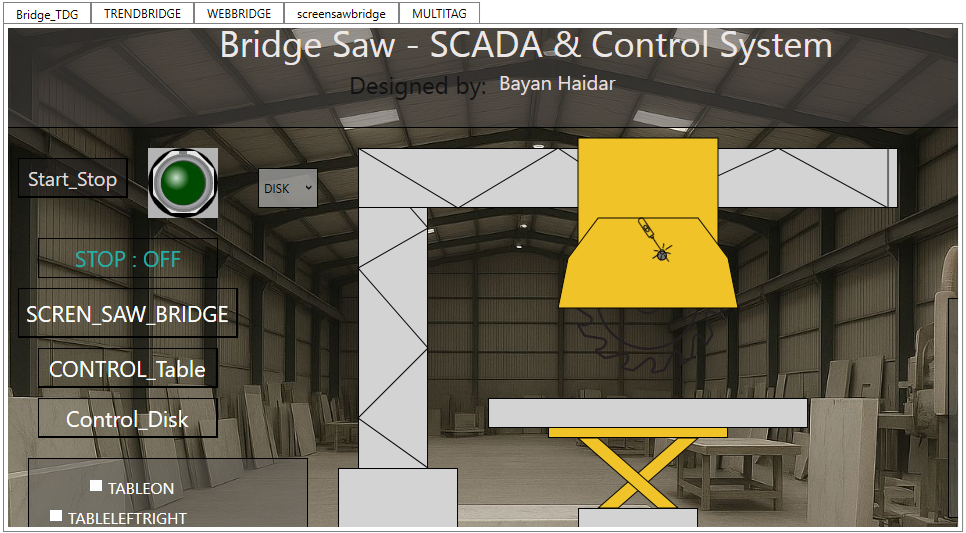

Rising global demand for natural

stone—marble, granite, and engineered

materials—is accelerating the industry's shift

toward automation, precision cutting, waste reduction, and improved safety. Fabrication

shops are rapidly moving from manual

processes to CNC machines with intelligent

operator interfaces.

This student project features an ADISRA

SmartView application that simulates and

controls a modern stone-cutting machine.

The interface demonstrates how industrial

automation software streamlines key

operations, including cutting-head

positioning, spindle speed, water flow, and

cut sequencing, while introducing students to

essential concepts such as predictive

maintenance, production monitoring, energy

efficiency, and operator safety.

As residential solar adoption continues to

grow worldwide, homeowners increasingly

rely on smart monitoring systems to track

energy production, storage, and usage.

Modern solar setups include panels,

inverters, batteries, and grid connections, all

of which must work together efficiently to

maximize energy savings and reliability.

This student project showcases an interactive

interface for monitoring a home solar energy

system. The application visualizes key

components—including solar panels,

inverters, battery storage, the electrical grid,

and additional supporting

equipment—allowing users to observe real-

time status, power flow, and system

performance.

Modern buildings rely on safe, efficient

elevator systems, and real-time monitoring

plays a crucial role in ensuring smooth

operation. From tracking usage patterns to

detecting faults early, data-driven oversight

helps reduce downtime, improve safety, and

enhance the tenant experience.

This student project features an elevator

management interface that simulates how

building operators monitor and maintain

multiple elevators. The application includes

real-time status displays, performance data

trend charts, and an alarm system to detect

issues such as door malfunctions, overload

conditions, and extended wait times.

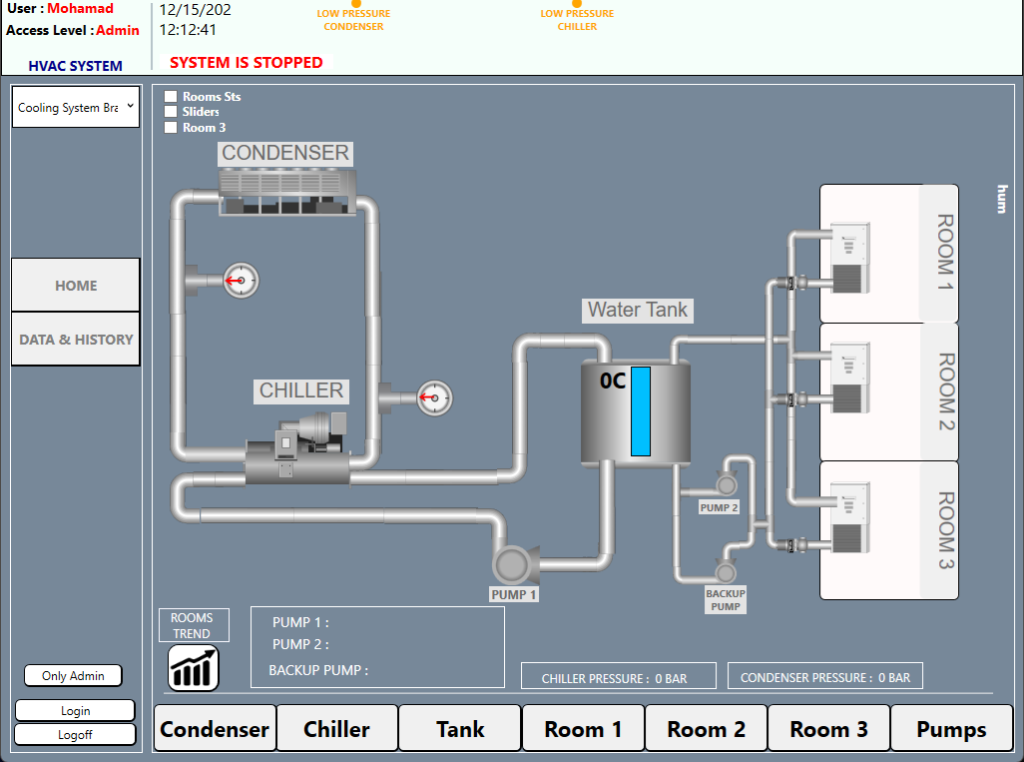

With rising energy costs and a growing focus

on sustainability, modern HVAC systems are

becoming more innovative and more data-

driven. The industry is trending toward real-

time monitoring, predictive maintenance, and

energy-efficiency optimization to improve

comfort while reducing operational expenses.

This project showcases an HVAC monitoring

application that collects and stores

temperature data across multiple

environments and visualizes it through line

charts and bar graphs. By separating each

zone, the interface highlights performance

trends and inefficiencies, demonstrating how

data visualization supports more intelligent

climate control and more efficient building

management.

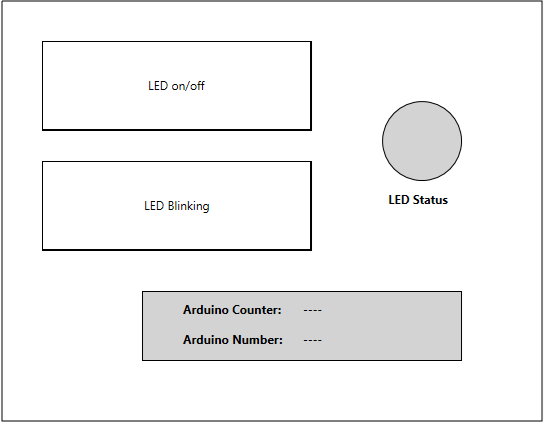

This student project demonstrates how easily

ADISRA SmartView can connect to an

Arduino, a platform that has evolved from a

hobbyist favorite into a widely used

industrial-grade edge device. Using the

Modbus Serial protocol—a lightweight and

reliable method for data exchange—the

setup requires no additional hardware. The

Arduino uses its Modbus library to

communicate with ADISRA SmartView over

USB.

In this example, you will learn how to:

– Send data from Arduino to a SCADA system.

– Receive data from SCADA back to Arduino.

– Send and receive data simultaneously for

full bidirectional control.

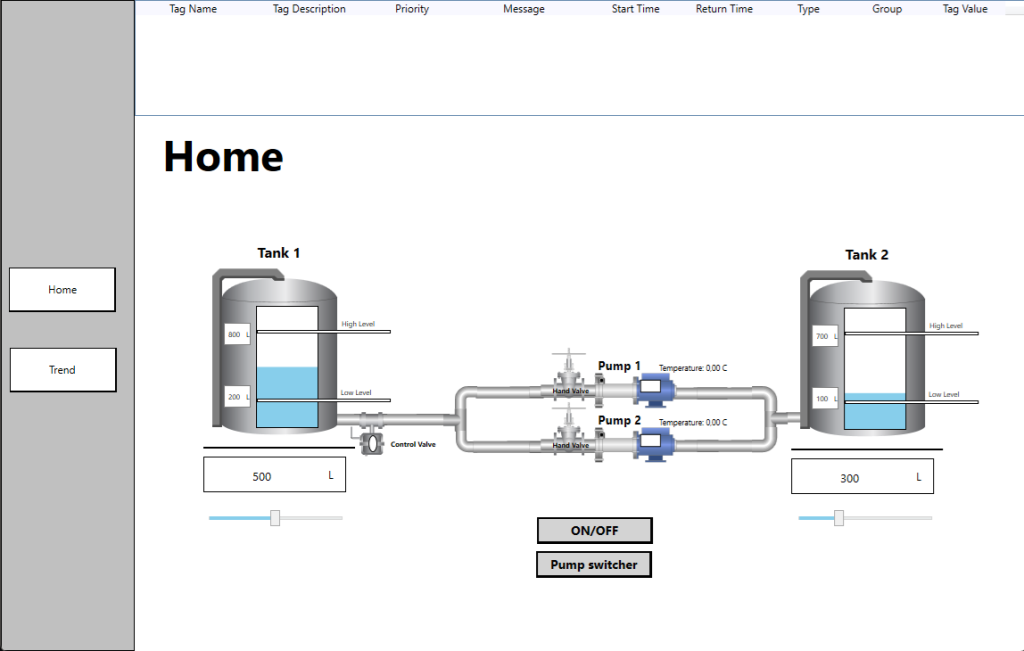

Water Tank Transfer System

As global demand for clean water continues

to rise, utilities and industrial facilities are

increasingly adopting smart monitoring and

control systems to improve reliability and efficiency.

This student project uses ADISRA SmartView

and ULEAP to simulate a two-tank water

transfer system. It provides a practical

foundation for understanding how real

facilities manage water movement, maintain

safe operating levels, and respond to system

events.

Key Features Implemented

– Primary and backup pumps to manage

water transfer between tanks

– Adjustable high/low level sensors with input

validation to prevent errors

– Real-time simulation of tank levels and

pump activity

SCADA interface with multiple pages,

including:

– Alarm page for system events

– Trend page to visualize water level changes

– Navigation tabs for tank switching

– Pump toggle controls

– Custom reusable templates to streamline

development and maintain consistency

MAKE ADISRA YOUR SOURCE FOR ALL OF YOUR INDUSTRIAL APPLICATION NEEDS

Sign up for our newsletter or contact us to learn more about our products.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.