Key Technologies Driving IIoT Adoption

The global Industrial Internet of Things (IIoT) market is expected to reach USD 194.4 billion in 2024, with growth projections to USD 286.3 billion by 2029. This reflects a compound annual growth rate (CAGR) of 8.1%, according to MarketsandMarkets analysts. IIoT is a critical driver of digital transformation across all industries as rising demand for automation intensified competition, increased cybersecurity concerns, and technological advancements shape manufacturing’s future.

Edge computing is a major factor fueling IIoT’s growing demand. Last week, ADISRA’s Blog discussed how the advantages of analytics at the edge are being recognized and how the increased deployments are significantly contributing to the growth.

Other driving forces pushing growth are heightened security concerns, advancements in sensor technology, and the integration of 5G. Strong cybersecurity measures are required as the number of connected devices grows and the potential entry points for cyber threats increase. Modern sensors are becoming more sophisticated and capable of capturing a broader range of data with greater accuracy. Additionally, the expanding use of 5G wireless technology accelerates IIoT adoption by providing faster multi-gigabit data speeds, ultra-low latency, enhanced reliability, massive network capacity, and more consistent user experiences.

IIoT and its technology enablers offer enhanced monitoring and control capabilities for industrial processes and machinery, providing a more comprehensive view of operations.

Evolution of HMI in the Age of IIoT: Bridging Interfaces and Expanding Capabilities

The definition of Human-Machine Interface (HMI) and Supervisory Control and Data Acquisition (SCADA) software has evolved. The terms are often used interchangeably and in many cases, the same software package is applied to both uses. This has led to confusion about the boundaries between the two, largely because users interact with both in similar ways. However, the key distinction lies in their application and architecture.

A similar evolution is occurring with HMI and IIoT. HMI software is transforming in form, capabilities, expectations, and purpose. Traditionally, an HMI is a system or device that enables humans to interact with machines, systems, or devices—such as field equipment, Programmable Logic Controllers (PLCs), and sensors—through a visual interface. Today, with IIoT and edge computing, HMI can be deployed in new ways. For example, the visual interface may be accessed through a web browser or mobile device, while the HMI software runs headless on IIoT or edge devices. This flexibility allows users to display analytical data wherever they choose, expanding the reach and functionality of HMI in modern industrial environments.

Enhancing IIoT Efficiency with Remote Management in HMI/SCADA Applications

Remote machine monitoring through alternative methods of displaying data from HMI and SCADA applications has become a core aspect of IIoT implementations. This connection enables operators to remotely visualize machine performance, optimize operations, transmit production data to engineering teams, and provide management with summary reports and analysis. However, as the number of IIoT and edge devices in an organization’s ecosystem grows, the demand for built-in remote management tools within HMI/SCADA software becomes increasingly critical. Such tools enhance operational efficiency by allowing real-time monitoring and control and simplify configuration, maintenance, and troubleshooting, making them essential for managing modern industrial environments effectively.

Remote management refers to the ability to remotely configure, monitor, and control systems and devices through a network connection. This includes tasks such as managing applications, starting or stopping runtimes, accessing logs, and handling licenses all from a centralized interface without the need for on-site access.

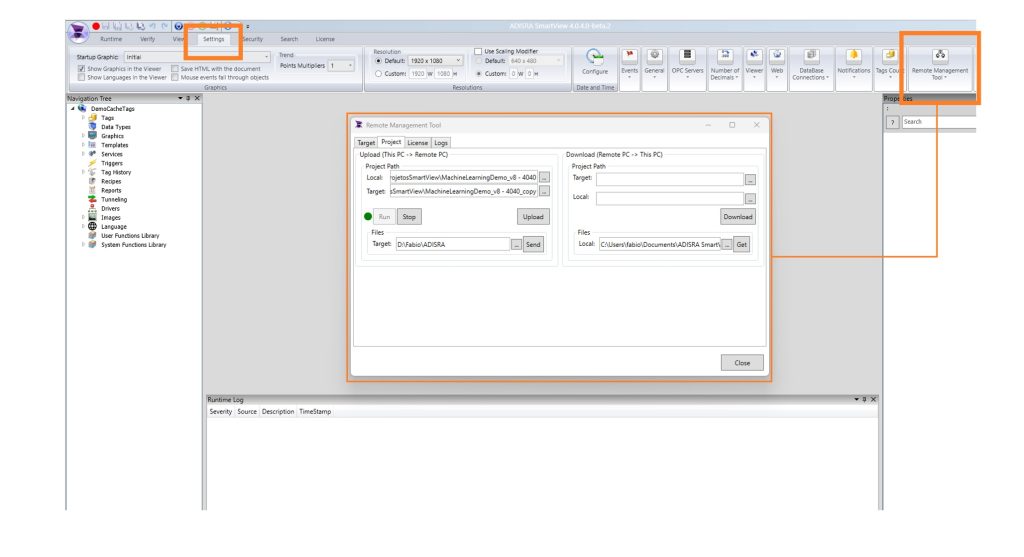

Accessing and manually updating a target server can often be challenging especially when it’s located on the factory floor inside a secure industrial enclosure or housed in a data center. Traditionally, installing new versions of HMI/SCADA software or updating server-side applications involves manually copying files and running installers. It is a time-consuming process that can be prone to human error. However, the ADISRA SmartView remote management tool offers a built-in remote management system that streamlines the entire process.

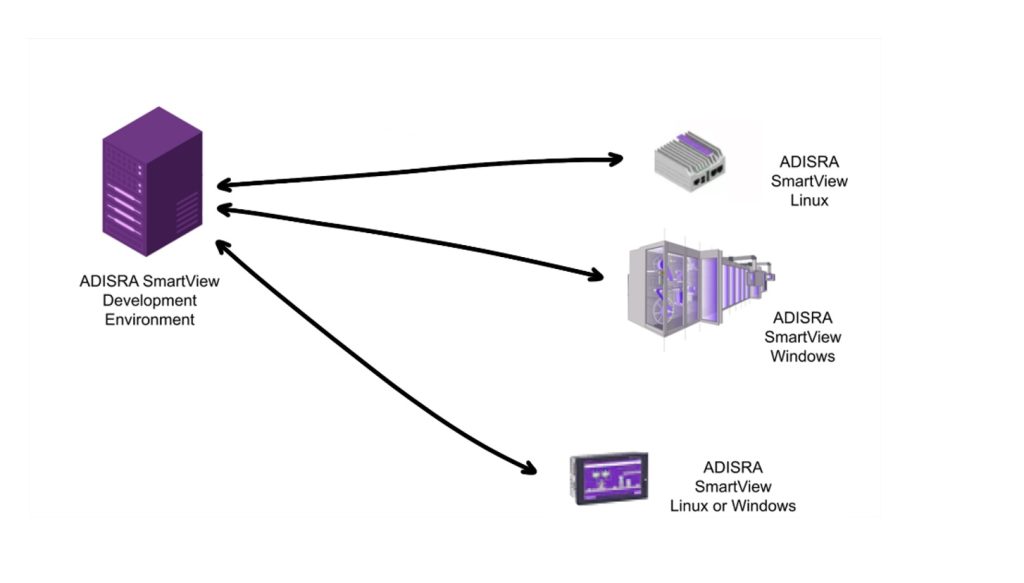

ADISRA SmartView offers a multiplatform solution (compatible with both Windows and Linux) designed to simplify the configuration and management of systems across the plant ecosystem. The ADISRA SmartView development environment enables seamless remote connections to any ADISRA SmartView run-time environment embedded on IIoT and Edge devices within the same network. This allows users to perform tasks such as downloading or uploading applications, starting or stopping remote runtimes, accessing runtime logs, and managing software licenses—all from a centralized location.

Users can easily and remotely install and license computers to run ADISRA SmartView with this tool, deploy their developed applications, and start operations without being on-site. Additionally, future updates—whether to the application or to ADISRA SmartView itself—can be handled remotely, replacing the manual process with a faster, more efficient, and error-free approach. It saves time, reduces the chance of mistakes, and significantly improves operational efficiency.

ADISRA SmartView’s remote management utilizes a microserver architecture, meaning it operates on a small, energy-efficient server that leverages the Remote Procedure Call (RPC) framework. This setup allows a client application to directly invoke methods on a server application, regardless of its environment, while ensuring a secure, encrypted connection for safe and reliable communication.

You can create a more extensive and integrated system for tracking and managing network-attached devices and IIoT equipment by leveraging ADISRA SmartView’s built-in remote management capabilities along with ADISRA SmartView’s SNMP driver to connect to a comprehensive network monitoring tool that supports IIoT device monitoring. This approach ensures broader application and device monitoring across the entire IIoT ecosystem, offering real-time insights and enhanced control over both industrial and network components.

In an IIoT environment, this functionality empowers users with greater flexibility, enabling efficient system management, real-time monitoring, and streamlined maintenance without the need for on-site intervention. The tool enhances operational efficiency, minimizes downtime, and supports scalable, secure remote access, making it indispensable in modern industrial settings.

Experience ADISRA SmartView remote management by downloading a software trial from our website here.

Benefits of using Remote Management

Simplified Remote Configuration: The tool enables remote configuration of systems on target IIoT platform, reducing the need for on-site personnel. This is particularly valuable in geographically dispersed IIoT environments, allowing for seamless setup and management from any location.

Multi-Platform Compatibility: Since the tool supports both Windows and Linux, it offers flexibility across different platforms, making it adaptable to various industrial setups commonly found in IIoT ecosystems.

Efficient Application Management: Users can remotely download and upload applications to the target platform, facilitating faster deployment and updates of IIoT systems without interrupting ongoing operations. This increases efficiency and minimizes downtime.

License Management: The tool simplifies license management by enabling remote handling of software licenses. This ensures compliance and prevents operational delays caused by licensing issues, which can be crucial for maintaining uninterrupted IIoT services.

Cost Savings: Remote access from the development environment reduces the need for on-site technicians, travel, and maintenance leading to significant cost savings in managing IIoT systems spread across multiple locations.

Improved Uptime and Performance: With remote start/stop and real-time monitoring of runtimes, operators can respond to system failures or anomalies quickly, leading to better system uptime and performance which is critical in industrial environments where downtime is costly.

Remote management Tool is a valuable asset for IIoT environments, enhancing operational efficiency, reducing costs, and enabling scalable flexible system management.

Conclusion

The role of remote management in IIoT will continue to expand as industries embrace digital transformation; remote management is becoming a modern industrial operations’ cornerstone with its ability to improve operational efficiency, reduce costs, and ensure real-time control. As the market grows, businesses integrating IIoT remote management solutions into their operations will be better positioned to succeed in the competitive industrial landscape.

The combination of ADISRA SmartView’s remote management capabilities and its SNMP driver offers a powerful solution for comprehensive IIoT monitoring and control. By integrating network-attached devices and IIoT equipment into a single, scalable platform, businesses can achieve real-time insights, improve operational efficiency, and reduce the need for on-site maintenance. This solution not only minimizes downtime but also provides a secure, scalable approach to managing complex industrial systems while positioning companies to thrive in an increasingly connected and data-driven industrial landscape.

By leveraging ADISRA SmartView’s remote management, companies can transition from reactive to proactive strategies, driving innovation and operational excellence in the digital age.