As the winds of autumn stir and shadows lengthen, eerie trends are creeping into the manufacturing world that could haunt operations long after Halloween has passed. These haunting realities reveal how technology, sustainability, and the workforce are transforming the industry in ways that can be both exciting and, at times, unnerving. Here’s a look at some of the most spine-chilling trends.

- The Ghosts of Legacy Systems

The Perks of Embracing Haunted Legacy Systems

In the shadowy halls of industrial automation, many still cling to the ancient, creaking systems of the past, haunted by their time-tested reliability. Though the eerie winds of change howl with rapid advancements in automation and control, a chilling truth remains: these ghostly relics endure, proving their resilience against the march of time. The spirits of legacy technology linger, casting a spell of stability that keeps many from daring a swift transition into the unknown. The industrial world, it seems, prefers to move cautiously, guided by the ghosts of systems past.

The Chilling Advantages of Legacy Systems

The Cost-Effectiveness of the Undead: Legacy systems often emerge as the most cost-effective ghouls in industrial automation. Their initial investment has long been buried and forgotten, and continuing to use them spares companies the spine-chilling expense of upgrading to newfangled technologies. Businesses avoid the monstrous capital expenditure of modern systems by keeping these relics alive.

Haunted Compatibility and Integration: Legacy systems are deeply entwined with a company’s operations, like spectral threads connecting every process. Their compatibility with existing equipment ensures that continuing to rely on them avoids the perilous risks and cursed complexities of integrating new technologies into the fray.

Reliability of the Resurrected: These products have weathered the dark passage of time, proving their resilience. Their long-term performance weaves a tale of reliability that no freshly awakened product can hope to rival. In industries where a system failure could unleash chaos, these ancient machines remain crucial sentinels against catastrophic disruption.

The Ghostly Expertise of the Workforce: Many industries are haunted by a workforce that knows these legacy systems inside and out, their knowledge passed down through the generations like a secret spell book. This expertise, sharpened over years of eerie familiarity, ensures the efficient management of these ancient systems, keeping them running like well-oiled phantoms at night.

The Dark Downsides of Legacy Systems

The Curse of Obsolescence: The greatest dread of legacy systems lies in their creeping obsolescence. As manufacturers focus on newer, shinier technologies, support for these aging relics begins to wither away. Spare parts become scarce, and servicing them becomes a haunting quest, leaving companies vulnerable to breakdowns and decay.

Energy Vampires: Older systems, like lurking energy vampires, drain more resources than their sleek, modern descendants. Their inefficiencies feed on higher operational costs over time, and their slower, less precise nature can sap productivity, leaving companies haunted by lost potential.

The Trap of Inflexibility: Expanding or transforming production processes with legacy systems can be a monstrous challenge. These ancient machines are often inflexible, trapping companies in a coffin of stagnation, unable to adapt to shifting market forces or grow their operations without a fight.

Ghostly Limitations: While steadfast, some legacy systems lack modern technologies’ supernatural powers. Without advanced features, these spectral machines can chain a company to the past, unable to rise to the evolving demands of the market or embrace the technological advancements lurking just beyond the veil.

Haunted Vulnerabilities: Legacy systems linger like ghosts in the machine, haunting operations with shadowy security vulnerabilities. As these outdated systems age, they become doorways for lurking cyber ghouls to slip in and wreak havoc.

Sometimes, keeping legacy systems alive feels like the safer path through the haunted corridors of industrial operations. The cost of resurrecting new hardware may seem too monstrous, or perhaps, in certain niche industries, newer equipment does not exist. Some may argue that the blood, sweat, and years poured into maintaining these relics outweigh the allure of venturing into the unknown with new technologies.

But when it comes to critical infrastructure, these arguments lose their power, like ghosts fading in the daylight. The longer these ancient systems cling to obsolete hardware and software, the closer they creep toward a catastrophic failure—one that may be beyond repair. Spare parts vanish into the void, and the technicians who once knew their secrets have long since disappeared into the mists of time.

Summoning a new system, though daunting, brings countless benefits. ADISRA SmartView offers a platform for the modern age, fortified with security updates that fend off lurking cyber exploits and patches long since forgotten for older systems. These newer systems thrive on more powerful and stable operating systems, and with them come tools that breathe fresh life into operations: improved graphics, connectivity with both old and new hardware, and features that unlock greater efficiencies. From enhanced trends and recipe management to runtime configuration, alarm management, and web capabilities, the transformation is magical—banishing inefficiency and bringing your processes into the future.

Experience ADISRA SmartView by downloading a software trial from our website here.

2. Automation Zombies on the Rise Robotics

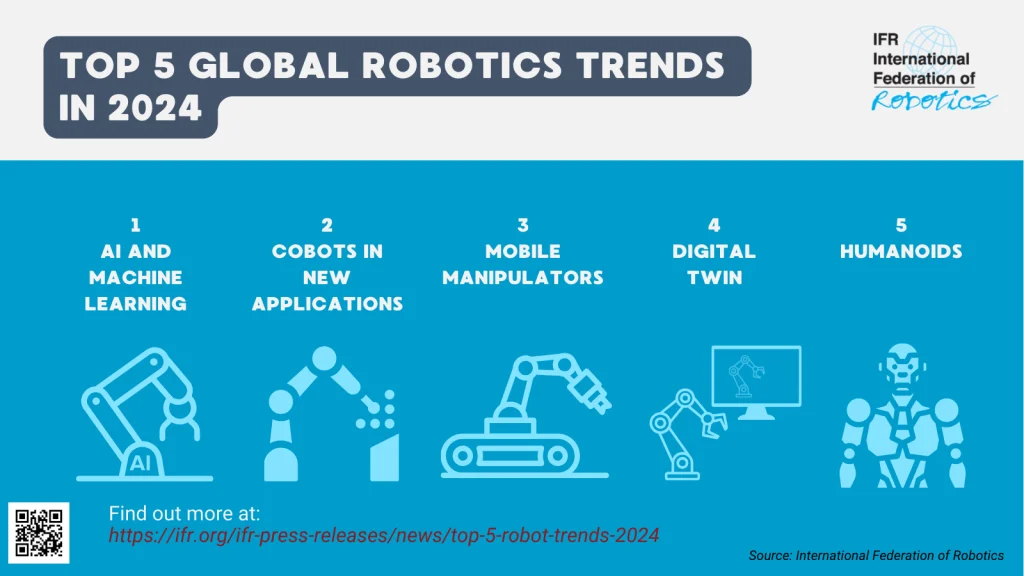

According to the International Federation of Robotics, a chilling 3.9 million operational robots roam the globe, and five sinister forces drive their rise. Artificial intelligence lurks at the core, infusing these machines with eerie intelligence. Collaborative robots, or cobots, work alongside humans like silent shadows in the night. Mobile manipulators glide through factories with uncanny precision, while digital twins mirror reality in a hauntingly perfect virtual reflection. And finally, humanoid robots emerge from the darkness, eerily resembling us, blurring the line between human and machine in this ever-advancing robotic underworld.

Artificial Intelligence (AI) and machine learning: The eerie rise of Artificial Intelligence (AI) in robotics and automation continues to cast its shadow across the industry, growing more powerful by the day. Robot manufacturers are summoning the forces of generative AI to create a more user-friendly interface, eliminating the need for specialized programming skills—like casting a spell to bring these machines to life with just a few clicks, without the arcane knowledge of old.

AI also haunts the world of predictive maintenance, playing a key role in preventing dreaded machine downtime. Like a digital oracle, machine learning algorithms analyze data from multiple robots performing the same tasks, seeking out hidden inefficiencies and whispering ways to optimize the process. And as with all good magic, the more data these algorithms consume, the stronger they become, performing their tasks with increasing precision and foresight. In this ever-evolving landscape, AI is proving to be a powerful force, reshaping robotics with every data-fueled incantation.

Collaborative robots: The eerie dance of human-robot collaboration continues to haunt the robotics world, growing stronger every day. As sensors, vision technologies, and smart grippers evolve frighteningly, robots now respond in real-time to changes in their environment, moving like silent phantoms alongside their human counterparts. In last week’s blog, we discussed autonomous robots (if you dare revisit it); these machines have become safer and more intuitive, working side by side with human workers without fear of danger.

The chilling reach of collaborative robots, or cobots, expands as robot manufacturers unlock new realms of application. Once considered a niche, cobot welding has transformed into a significant field of opportunity, particularly as the shortage of human workers continues to plague the industry. Universal Robots reported a spine-tingling 80% growth in its welding channel during the first nine (9) months of 2022 alone. But welding is just the beginning—cobots are creeping into agriculture, cleaning, and even the eerie silence of small manufacturing plants. They take on the heavy burdens, the repetitive motions that wear humans down, and venture into the dangerous corners of the workplace, where no human dares tread. The rise of cobots is unstoppable, an omen of what is to come.

Mobile manipulators: Mobile manipulators are creeping into the shadows of industries like automotive, logistics, and aerospace, taking over material handling tasks with eerie precision. These haunting machines combine robotic platforms’ ghostly mobility with manipulators’ dexterous arms, allowing them to navigate through complex environments and handle objects with sinister skill. Their ability to roam and grasp makes them essential for manufacturing applications, where they slink through factories like silent specters.

Digital twin: Digital twin technology is becoming a powerful and haunting tool, casting a virtual shadow on physical systems to optimize performance. As factories grow increasingly entwined with digital threads, robots are increasingly integrated into this eerie web. The digital twin—a spectral replica—absorbs real-world operational data, running simulations and foreseeing outcomes before they even occur.

Because this twin exists only in the ethereal realm of a computer model, it can be pushed to the limits, stress-tested, and altered with no risk to the physical world. All experiments unfold without danger in this dark mirror, ensuring no costly mistakes are made before reality is touched. It is a place where every outcome is predicted, and the physical world remains undisturbed until the twin has whispered its secrets.

Humanoid Robotics: Robotics is creeping ever closer to eerie advancements in humanoid forms. With their unsettlingly human-like design—two arms, two legs—these robotic figures slink into work environments originally made for humans, offering a disturbing flexibility. As their popularity rises, the specter of cost looms large, with their success depending on their ability to outcompete other well-entrenched robotic solutions like mobile manipulators. But there’s another, more ghostly challenge lurking in the shadows—human-robot interaction.

Enabling these humanoids to understand natural language and take voice commands without prior training remains a daunting task. It is as if these machines, with their cold, metallic forms, still struggle to grasp the nuances of human communication. Yet, despite these eerie hurdles, more and more players are entering the haunted market—Optimus by Tesla, Digit by Agility Robotics, and Eve and Neo by 1X are just a few of the spectral newcomers vying for dominance in the humanoid realm.

The question is, will these human-like figures truly rise from the shadows, or will they be overshadowed by their older, more established robotic kin? Only time will tell what these mechanical phantoms are truly capable of.

3. Cyber Ghouls Lurking in the Shadows

Cybersecurity threats have taken a sinister turn as manufacturing grows more interconnected. Hackers and cyber ghouls lurk in the shadows, waiting to prey on vulnerabilities in Industrial Control Systems (ICS) and SCADA platforms. As manufacturers digitize their operations, the risk of falling victim to a cyberattack grows, threatening eerie shutdowns, data theft, and even dangerous safety hazards.

Amid this rising terror, many cybersecurity standards are meant to defend against these digital phantoms—like the Center for Internet Security (CIS), the Interconnection Security Agreement (ISA), the EU Cyber Resilience Act, Cloud Security Alliance, ISO, NIST, and more. Yet, navigating this haunted maze of standards can be bewildering. Which spell of protection should you follow to safeguard your manufacturing environment?

When IT and OT merge, beware of the skeletons hiding in your IT closet, for they might reveal the cracks in your fortress.

This Halloween, may your defenses be as stealthy as a black cat slipping through firewalls and as secure as your most encrypted passwords. Stay sharp, stay spooky, and keep those digital ghosts at bay!

4. The Curse of the Skills Gap

A chilling shortage of skilled workers continues to haunt the manufacturing industry like a ghost that refuses to leave. As seasoned workers fade into retirement, manufacturers are left scrambling to fill the void with fresh talent, but the skills needed seem to vanish into the night. This widening gap threatens productivity and leaves businesses vulnerable to costly mistakes, inefficiencies, and even safety horrors as new technologies demand specialized knowledge that’s becoming as rare as a full moon on Halloween.

The talent gap yawns wide, and the numbers are truly frightening. According to the latest figures from Forbes, there are a staggering 600,000 vacant positions in the industry right now, with another 3.8 million jobs expected to rise from the crypt by 2033. But it’s not just a skills gap that’s plaguing the industry—there’s a haunting lack of applicants altogether.

Three dark forces drive this skills gap:

1. The insatiable growth of the industry, summoning the need for more workers of all types—from entry-level laborers to skilled production operators to engineers with a mastery of their craft.

2. Evolving skill requirements, spreading across technical manufacturing expertise, digital know-how, and the elusive soft skills that bind them together.

3. A shortage of souls willing to step into the void, whether skilled or unskilled, leaving manufacturers in desperate need to retain the precious talent they still have. Attracting and keeping this talent has become the industry’s most terrifying challenge, with over 65% of respondents in the National Association of Manufacturers’ (NAM) outlook survey for Q1 2024 naming it their greatest business fear.

The industry is trapped in a race against time, as this ghostly gap continues to widen—will manufacturers find the skilled hands they need, or will they be forever haunted by the specter of lost talent?

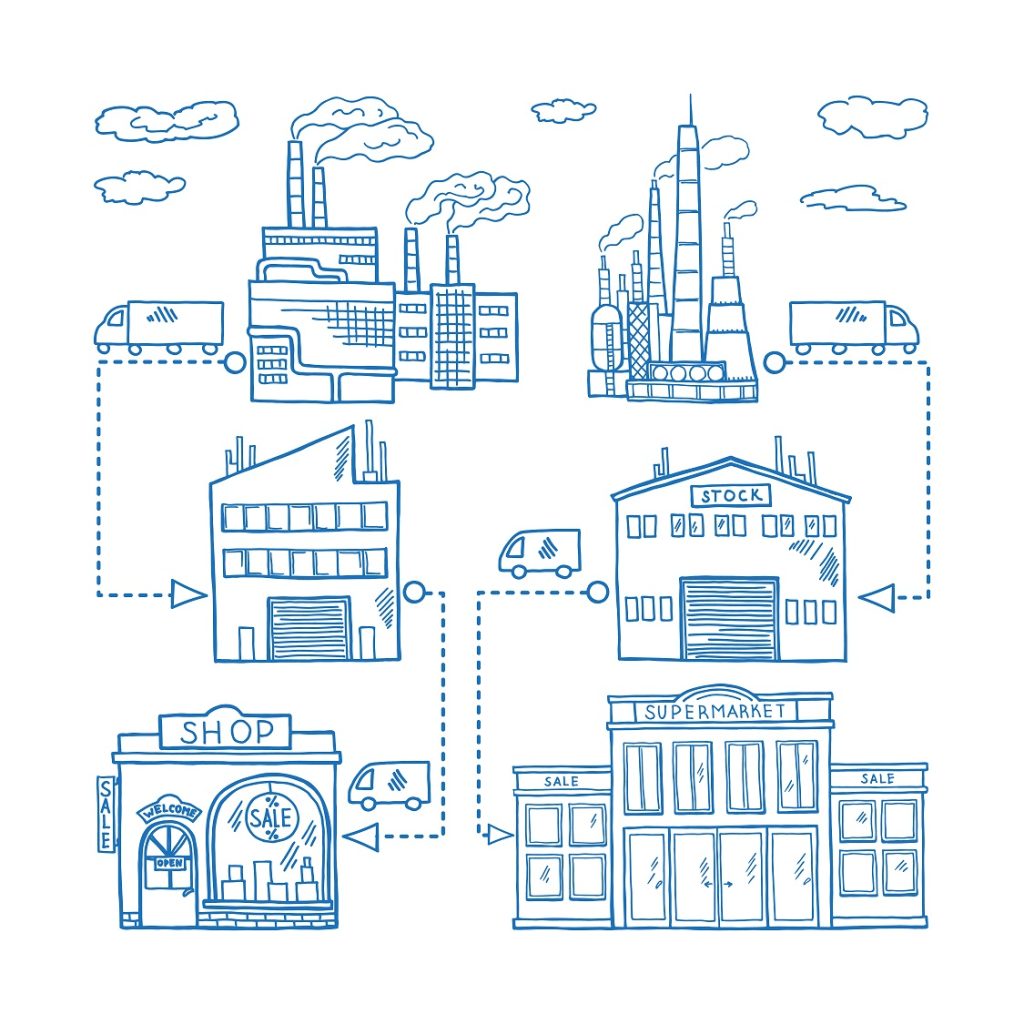

5. Supply Chain Gang

The global supply chain has been besieged by ghastly disruptions as if haunted by a sinister force. Phantom inventory and ghost shipments have become frighteningly familiar as manufacturers face chilling shortages, unpredictable lead times, and rising costs. The uncertain future of the supply chain looms like a dark cloud, leaving manufacturers haunted and forcing them to rethink their sourcing and logistics strategies—lest they fall victim to the next frightful shock.

But a new dawn is creeping through the fog, enabled by the eerie magic of technology. A new paradigm is emerging from the shadows, one where organizations can swiftly respond to daily requests, predict and prevent problems before they become nightmares, and exorcise inefficiencies with precision. This shift offers greater visibility, transparency, and traceability, helping companies become more resilient to future supply chain shocks that may lurk in the darkness.

Yet even in this brave new world, data remains a beast to be tamed. Millions of data points are generated daily from the sprawling supply chain, fed by the proliferation of digital technologies, IoT devices, and advanced tracking systems. This deluge of data has spawned new silos within organizations, creating fragmented, disconnected data sets that can lead to duplication, misinterpretation, and confusion—a spectral problem that grows more terrifying by the day. Data fragmentation prevents companies from crafting a holistic view of their haunted supply chain.

As AI and advanced technologies continue to shape the core of supply chain management, manufacturers must confront these lurking challenges and banish the chaos—or risk being haunted by inefficiencies and disruptions for years to come.

6. AI’s Witching Hour

Artificial Intelligence (AI) is casting a long shadow over the news as people begin to truly grasp its eerie potential and untold power. According to MarketsandMarkets research, AI is projected to reach a staggering $1.34 trillion by 2030—a sum that feels almost otherworldly. But what lurks within AI’s rise are four distinct forms, each representing a chilling evolution in the world of technology.

Reactive Machines – These AI entities are like soulless automatons, built to perform a single task with no capacity for learning. They follow pre-determined rules, mindlessly reacting to situations without ever understanding the past, like mechanical phantoms bound to their eternal programming.

Limited Memory – A step closer to the living, limited memory AI peers into the past, observing objects or situations over time. These ghostly entities can combine past and present data, shaping their actions based on both—offering glimpses of insight yet still tethered to their programming.

Theory of Mind – Theoretical and yet to be born, this AI would be capable of something far more unsettling: understanding emotions, thoughts, and intentions. Imagine a machine capable of grasping the inner workings of another mind—a chilling concept, not yet real, but one that lingers on the horizon like a shadowy figure in the distance.

Self-Aware AI – The ultimate, and perhaps most haunting, form of AI. This entity would possess self-awareness, a deep understanding of its own existence, and a sense of identity. Such a being would reflect on its own actions, learning and growing from its experiences in ways that could rival human thought. It is the kind of intelligence that could send shivers down one’s spine, contemplating its place in the world and the power it wields.

AI offers great promise in predictive maintenance, quality control, and automation. However, for many, it’s still the witching hour. The challenge lies in harnessing AI’s full potential, as poorly implemented algorithms can lead to spooky surprises like faulty predictions or unintended downtimes. Those who fail to master AI risk falling under its spell, with results that are more trick than treat.

History

Halloween, celebrated annually on October 31, derives its name from “All Hallows Eve,” the evening before All Saints’ Day, a Christian holy day.

With origins among the oldest holidays, Halloween traces back to Samhain, an ancient Gaelic harvest festival observed in Celtic regions like Scotland, Ireland, and Wales. The Celts believed that on the night before the new year, the boundary between the living and the dead became blurred, allowing the spirits of the deceased to return to Earth.

Over time, Samhain merged with Christian observances of All Saints’ Day and All Souls’ Day, which shaped modern Halloween’s focus on spirits and the dead.

Today, Halloween has evolved into a festive day filled with activities such as trick-or-treating, carving jack-o-lanterns, wearing costumes, and enjoying sweet treats.

While Halloween remains popular in Celtic regions, its celebration has grown in other European countries like England, France, and Germany. However, the popularity of the holiday in these regions does not quite match the enthusiasm seen in the United States and Canada.

Happy haunting!

ID 156230218 | Industrial Factory © Tartilastock | Dreamstime.com

ID 93523746 | Industrial © Onyxprj | Dreamstime.com

ID 116071935 | Industrial Artificial Intelligence © Ernest Akayeu | Dreamstime.com

ID 116071935 | Industrial Artificial Intelligence © Ernest Akayeu | Dreamstime.com