We look ahead with optimism to the technological trends poised to shape industrial automation in 2025. Building on the lessons of the past year, the industry is well-positioned to embrace cutting-edge innovations that drive progress, efficiency, and growth.

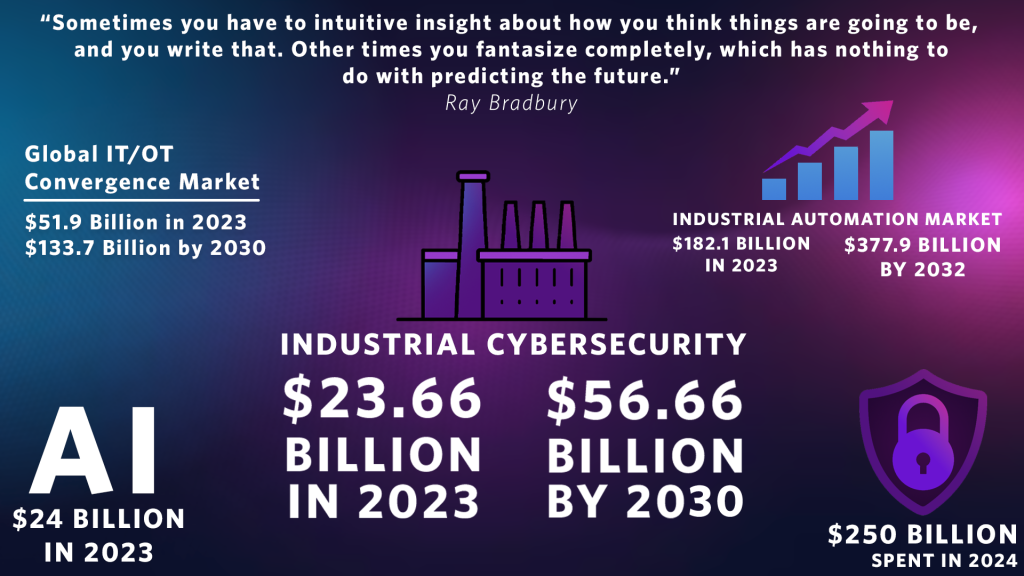

The Industrial Automation Market was valued at $182.1 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 8.45%, reaching $377.9 billion by 2032, according to SNS Insider Research. This impressive growth is propelled by advancements in robotics, sensors, and automation systems which are revolutionizing industrial processes. These technologies are not only enhancing efficiency and reducing costs but also establishing automation as a cornerstone for maintaining a competitive edge in an ever-evolving marketplace.

With this momentum in mind, here are my technology predictions for 2025.

The year 2024 marked a significant milestone for artificial intelligence (AI). While AI itself is not a new concept—it has existed since the early 1900s, with breakthroughs beginning in the 1950s—it has become an omnipresent force in today’s world. From transforming how we navigate transportation to reshaping communication and entertainment, AI permeates nearly every aspect of our lives. As it continues to evolve, AI is becoming an ever more integral part of modern society. Companies are pouring billions of dollars into advancing AI technologies, driving its growth and innovation at an unprecedented pace.

Artificial intelligence has firmly established itself as the most heavily funded sector of 2024 from a venture capital perspective, with startups securing over $24 billion in investments to date. This unprecedented influx of capital is driven by groundbreaking advancements in generative AI, natural language processing, and machine learning technologies.

AI is often perceived as “just another new industry.” However, this perspective is narrow and overlooks a critical insight: the current AI paradigm is not merely an industry or a standalone technology. Instead, it represents a convergence—a tipping point—that is simultaneously transforming and expanding business models across multiple industries.

Predictive maintenance has been a key focus in industrial automation for several years. According to Verified Market Research, the Industrial Predictive Maintenance Market was valued at USD 7.57 billion in 2023 and is expected to grow to USD 66.52 billion by 2031, with a robust CAGR of 29.6% during the forecast period (2024-2031).

Looking ahead to 2025, predictive maintenance will continue to advance due to its significant benefits. By enabling proactive scheduling of maintenance activities, it enhances operational efficiency, provides early warnings of potential equipment failures, and minimizes unexpected downtime. Additionally, it delivers substantial cost savings by reducing unscheduled downtime, avoiding unnecessary part replacements, and cutting labor expenses.

Simplify Predictive Maintenance with ADISRA SmartView and KnowledgeView

ADISRA SmartView features a built-in rule-based system, offering HMI/SCADA developers an intuitive interface to create predictive maintenance solutions for their equipment. This system leverages predefined rules, derived from expert knowledge and historical data, to trigger maintenance actions when specific conditions are met.

Rule-based systems are an excellent starting point for organizations transitioning from reactive to proactive maintenance. They are easy to implement and highly effective in addressing known failure patterns, helping businesses improve efficiency and reliability.

Explore ADISRA SmartView by downloading a software trial from our website.

For more advanced predictive maintenance, KnowledgeView delivers cutting-edge capabilities. This cloud-based tool uses machine learning and predictive algorithms to enhance equipment reliability and monitoring. By analyzing real-time operational data, KnowledgeView identifies patterns and anomalies that indicate wear, malfunctions, or the need for maintenance.

KnowledgeView empowers operators to anticipate issues before they occur, reducing downtime, extending asset life, and lowering maintenance costs. Its scalable, cloud-based infrastructure ensures easy accessibility, making it ideal for companies pursuing data-driven maintenance strategies.

Try KnowledgeView by requesting a temporary account on our website.

The industrial cybersecurity market is undergoing rapid expansion, fueled by the increasing connectivity of industrial systems, rising awareness of cyber threats, and the growing enforcement of regulatory standards. As industries become more dependent on interconnected technologies, the urgency to protect critical systems from evolving cyber risks has never been greater.

Emerging technologies bring both opportunities and challenges. While innovations like generative AI, hybrid cloud infrastructure, and quantum computing create new attack vectors for cybercriminals, they also offer powerful tools for fortifying defenses against these threats.

According to Omdia’s eBook, Digital Resilience: Securing Devices for the Modern Enterprise, global cybersecurity spending is reaching $250 billion in 2024. The industrial cybersecurity market alone was valued at $23.66 billion in 2023 and is projected to grow to $56.63 billion by 2032, with a CAGR of 10.5% from 2024 to 2032 according to Straits Research.

Effective industrial cybersecurity strategies include securing IT and OT network architectures, implementing strong access controls, monitoring for anomalies, and deploying advanced threat detection and response mechanisms. These measures are critical for safeguarding industrial processes’ integrity, availability, and confidentiality and ensuring operational continuity, safety, and economic stability. Demand for robust industrial cybersecurity solutions continues to rise, driving innovation and investment in protective technologies as cyber threats grow in complexity.

Continuous monitoring to detect potential threats early is becoming a standard practice, supported by increasingly robust authentication measures. Additionally, as supply chains become more interconnected across manufacturers, suppliers, distributors, and retailers, cybersecurity within the supply chain has grown paramount. With the supply chain only as strong as its weakest link, a successful cyberattack can lead to widespread repercussions, including data breaches, financial losses, reputational harm, and even physical danger.

In next week’s blog, we will delve into the critical role of cybersecurity in meeting new regulatory requirements such as NIS2, DORA, PCI 4.0, the UK Cyber Resilience Act, and the EU AI Act. We will also explore how these regulations strengthen organizational defenses in an increasingly connected and complex world.

The industrial network market is undergoing rapid transformation fueled by the growing demand for improved connectivity, efficiency, and automation in manufacturing. In 2025, connectivity will remain a key focus in industrial automation as the integration of sensors, PLCs, cloud platforms, and data silos becomes indispensable. Advanced technologies such as OPC UA over TSN (Time-Sensitive Networking) and MQTT Sparkplug are set to gain further traction, offering standardized, low-latency communication pathways between devices and cloud systems. Meanwhile, 5G technology, first introduced in 2019, will continue to revolutionize Industrial IoT (IIoT) by delivering unparalleled connectivity and real-time data-sharing capabilities. With its support for massive machine-type communications (mMTC) and ultra-reliable low-latency communication (URLLC), 5G will enable transformative applications like autonomous systems, remote monitoring, and predictive maintenance.

The convergence of IT and OT systems is increasingly blurring the boundaries between factory operations and enterprise management. The global IT/OT convergence market, valued at $51.9 billion in 2023, is projected to reach $133.7 billion by 2030, growing at CAGR of 14.5% from 2024 to 2030. This convergence offers substantial benefits, including enhanced efficiency, productivity, and data-driven decision-making. However, it also presents challenges such as increased security risks, integration complexities, and the need to upgrade legacy systems.

A key result of IT/OT convergence is the growing dominance of Industrial Ethernet IP, which accounted for 71% of newly installed nodes, according to HMS. The industrial Ethernet market is projected to reach $63.91 billion by 2028, growing at a CAGR of 15%, according to The Business Research Company. Celebrated for its high-speed data transfer, reliability, and scalability, Industrial Ethernet IP has firmly established itself as a cornerstone of modern industrial connectivity.

To generate actionable insights, data must be standardized, normalized, and aggregated effectively. Standardization harmonizes data from diverse sources into a consistent format, ensuring platform comparability. By 2025, IDC predicts that adopting data-as-a-product (DaaP) architectures will significantly reduce data silos and inefficiencies in large enterprises. This approach treats data as a valuable, managed asset, emphasizing repeatable processes and consistent, reliable outcomes. In an interconnected industrial landscape, DaaP will play a pivotal role in unlocking the full potential of organizational data, driving innovation and operational excellence.

ADISRA SmartView offers extensive support for a variety of industrial protocols, including Ethernet/IP, Modbus/TCP, OPC/UA, as well as protocols like MQTT, SNMP, and more, ensuring seamless data collection from industrial devices. It provides the versatility to store data in the cloud, in a historian, or across multiple databases. In addition to data storage, ADISRA SmartView integrates effortlessly with a wide range of popular databases, enabling advanced data aggregation and consolidation. This unified data can be utilized for local analytics or harnessed by its rule-based expert system to drive smarter decision-making and improve operational efficiency.

Explore ADISRA SmartView by downloading a software trial from our website.

Edge computing is poised for remarkable growth driven by the increasing need for real-time insights, a strong emphasis on operational efficiency, and the emergence of innovative business models. According to the International Data Corporation (IDC) Worldwide Edge Spending Guide, global spending on edge computing is projected to reach $228 billion in 2024, reflecting a 14% increase from 2023. This growth trajectory is expected to continue through 2028, with spending nearing $378 billion, maintaining a robust double-digit CAGR.

This transformative technology leverages real-time data from critical equipment and processes to significantly enhance operational efficiency and deliver actionable insights through advanced analytics.

As the Industrial Internet of Things (IIoT) ecosystem expands, sensor costs have decreased, and data volumes have surged, making edge computing indispensable. Edge computing minimizes latency and accelerates data processing by processing data at its source rather than relying on centralized data centers or cloud services. This capability enables real-time insights, smarter decision-making, and heightened efficiency.

The increasing adoption of IIoT devices, the proliferation of low-cost sensors, advancements in 5G networks, and the necessity for real-time data processing are fueling the demand for edge computing. These developments are paving the way for an era of data-driven operational excellence.

Analytics within edge environments is expected to be a significant growth driver. In this context, SCADA/HMI systems at the edge facilitate monitoring, control, and data execution directly at the source. By embedding algorithms in edge devices, computational power and decision-making are brought closer to the process itself, enabling faster responses and more accurate outcomes.

Use cases such as line control and precision monitoring exemplify the benefits of SCADA/HMI on the edge. For instance, smart factories equipped with motion, temperature, and climate sensors can dynamically adjust lighting, cooling, and other environmental controls to optimize power usage. This application showcases the potential of SCADA/HMI on the edge for real-time control and efficiency.

ADISRA SmartView is equipped to harness the power of edge computing. Featuring a built-in rule-based expert system, ADISRA SmartView transforms raw data into actionable insights. Its real-time expert system applies embedded rules to assess equipment health, enabling proactive system health monitoring. This capability ensures machinery operates at full capacity while minimizing unnecessary downtime for maintenance or unexpected or unexpected stoppage.

As we step into 2025, robotics is poised to accelerate the transformative advancements of recent years. Powered by cutting-edge developments in artificial intelligence (AI), machine learning, connectivity, control and drive technologies, and materials science, robots are becoming more agile, intelligent, and capable. These robots can now process sensory data to make real-time, self-evaluated decisions, offering deeper insights and greater adaptability with expert systems and machine learning.

Autonomous Mobile Robots (AMRs) are at the forefront of revolutionizing logistics and material handling. Unlike Automated Guided Vehicles (AGVs), which rely on fixed paths, AMRs utilize sensors and AI to navigate dynamically through environments with moving obstacles. Their versatility makes them indispensable for warehouses and manufacturing facilities where they transport goods, assist in picking and sorting, and even carry out sanitation tasks.

In a previous blog, we showcased how ADISRA SmartView was leveraged to automate an AMR robot. Click here to learn more.

Another prominent trend is the rise of Robotics-as-a-Service (RaaS). This innovative model allows companies to lease robots instead of purchasing them outright, dramatically reducing the cost of entry into automation. In 2025, RaaS providers are expected to enhance their offerings with comprehensive services, including maintenance, updates, and technical support, making robotics adoption and scalability more attainable.

As robots become more versatile, they continue to expand their potential applications. One standout example is Tesla’s Optimus Gen 2, introduced in 2024. This humanoid robot is designed to perform a broad array of tasks, from industrial manufacturing to household chores, demonstrating the incredible adaptability of modern robotics. Optimus Gen 2 pushes the boundaries of robotics, setting new benchmarks for innovation and functionality.

As these trends converge, robotics is reshaping industries and everyday life. The advancements in automation, intelligence, and versatility promise increased efficiency, innovation, and unprecedented opportunities for human-robot collaboration. With a promising outlook for 2025, the robotics landscape is set to redefine how we live and work.

I would be remiss not to highlight that sustainability in industrial automation remains a critical focus as we move into 2025. At its core, sustainability in this context involves leveraging technology to make factories and manufacturing processes more efficient while minimizing their environmental footprint.

The industry is actively advancing sustainability through various initiatives, such as developing smart factories, deploying robotics for recycling and waste reduction, and integrating renewable energy sources. In a previous blog, we highlighted how ADISRA SmartView was utilized in a solar energy application. Click here to read more about it.

These efforts aim to minimize environmental impact, optimize resource use, and promote a circular economy within industrial processes, paving the way for a more sustainable and efficient future in manufacturing.

Conclusion

As we venture into 2025, the industrial automation landscape promises to be more innovative, connected, and sustainable than ever before. From the rapid advancements in artificial intelligence and edge analytics to the growing importance of predictive maintenance and cybersecurity, these trends reflect a profound shift toward more intelligent, more efficient, and resilient industrial processes.

ADISRA SmartView is at the forefront of this transformation, empowering organizations with tools to harness cutting-edge technologies like predictive maintenance and analytics on the edge. By simplifying complex processes and enabling actionable insights, ADISRA SmartView supports businesses in achieving operational excellence, minimizing downtime, and staying competitive in an evolving market.

The convergence of technology, connectivity, and sustainability will redefine how industries operate and unlock new opportunities for innovation and collaboration. As we embrace these changes, the future of industrial automation in 2025 is poised to deliver unprecedented advancements that benefit industries, economies, and the environment alike.

Let’s step into this new era together, equipped with the tools and vision to thrive in a smarter, more connected world. Explore our offerings for more insights and solutions and see how ADISRA can support your automation journey.

ADISRA®, ADISRA’S logo, InsightView®, and KnowledgeView® are registered trademarks of ADISRA, LLC.

© 2025 ADISRA, LLC. All Rights Reserved.