Denis Panjuta is the founder of AI Academy, his post (link) prompted me to reflect on the different layers of AI and how they are depicted in literature, articles, and films. It’s fascinating to see how our perception of AI continues to evolve, influencing both public understanding and industry expectations. In my field—industrial automation—AI is playing an increasingly critical role in optimizing operations, enhancing decision-making, and driving innovation.

In 2013, the movie Her was released, telling the story of a lonely man navigating the final stages of his divorce. Seeking companionship, he purchases an advanced artificial intelligence system with the voice of Scarlett Johansson. As he interacts with the AI, he develops deep emotional connections, experiencing both profound joy and lingering uncertainty about the nature of his feelings.

The film envisions an AI system that closely mirrors human cognition, complete with complex decision-making abilities and emotional depth. However, while AI has made significant strides in recent years, today’s models are far from the sentient beings depicted in such stories.

What Her portrays is artificial general intelligence (AGI)—a level of AI that remains theoretical. Unlike today’s AI, which is built on sophisticated machine learning algorithms designed for specific tasks, AGI would have the capability to learn, reason, and perform any intellectual task a human can. This includes problem-solving, perception, language comprehension, and even analyzing and responding to complex emotions.

While AGI research is ongoing, there is no clear roadmap to achieving it. One promising area of exploration is neurosymbolic AI, which integrates neural networks with symbolic reasoning to improve learning and decision-making. However, despite continued advancements, true AGI remains a distant frontier in the world of artificial intelligence.

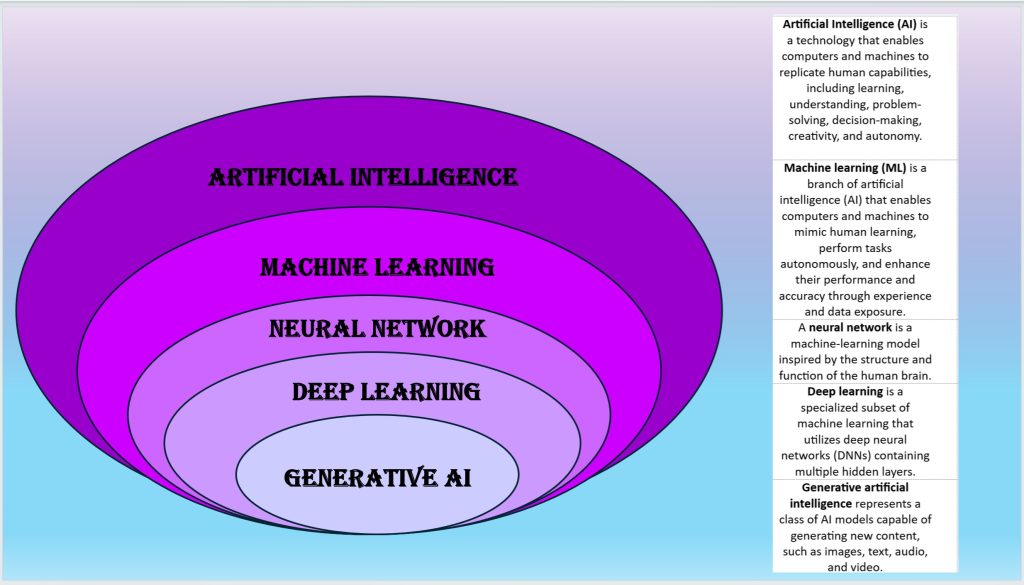

Neural Networks, Deep Learning, and Generative AI: Understanding the Differences

A neural network, also known as an artificial neural network (ANN) or simulated neural network (SNN), is a machine-learning model inspired by the structure and function of the human brain. It consists of interconnected nodes, or neurons, organized into layers that collaborate to process and analyze data.

Each neuron receives input, processes it, and transmits an output to neurons in the next layer. These connections are governed by weights, which are adjusted during training to improve the network’s accuracy and performance. Neural networks emulate the way biological neurons work together to recognize patterns, evaluate options, and reach conclusions. They form a crucial subset of machine learning and serve as the foundation of deep learning models.

One of the most well-known applications of neural networks is Google’s search algorithm. By leveraging neural network technology, it interprets complex search queries, delivering more relevant results based on context and meaning rather than relying solely on keyword matching.

Deep Learning: A More Advanced Form of Neural Networks

Deep learning is a specialized subset of machine learning that utilizes deep neural networks (DNNs), which contain multiple hidden layers. These hierarchical networks enable the processing of vast amounts of data, powering AI applications such as speech recognition, image analysis, and natural language processing.

Traditional machine learning models typically rely on simple neural networks with one or two computational layers. In contrast, deep learning models incorporate three or more layers—often extending to hundreds or even thousands—to facilitate sophisticated data processing. These additional layers allow deep learning models to extract complex features from raw data, enhancing their ability to perform advanced tasks.

One of deep learning’s greatest strengths is its ability to learn from both structured and unstructured data, enabling models to recognize characteristics, relationships, and patterns without explicit programming. Furthermore, deep learning models refine their outputs iteratively, continuously improving their precision and achieving high accuracy on complex tasks.

Deep learning is a key driver of data science and automation, enabling AI-powered applications and services that operate with minimal human intervention. It supports a wide range of technologies, including digital assistants, voice-enabled TV remotes, credit card fraud detection, self-driving cars, and generative AI.

Neural Networks in Industrial Automation

A prime example of neural networks in industrial automation is the use of vision systems for defect detection on production lines. Convolutional neural networks (CNNs) analyze images of manufactured products, identifying flaws or inconsistencies that may be too subtle for traditional inspection methods. This allows for real-time quality control, reducing defective products and optimizing efficiency in manufacturing processes.

Generative AI: Creating New Content

Generative artificial intelligence, commonly referred to as generative AI (Gen AI), represents a class of AI models capable of generating new content, such as images, text, audio, and video. These models learn from existing data and leverage deep learning techniques to produce original outputs, simulating human creativity and ingenuity.

Generative AI has a wide range of applications across industries. In the automotive sector, for instance, companies use it for various purposes, from engineering and vehicle design optimization to enhancing in-vehicle experiences and customer service. Generative AI helps refine mechanical parts to reduce drag in vehicle designs and aids in the development of advanced personal assistants. It is also utilized in the creation of new materials, microchips, and part designs, optimizing manufacturing processes and cutting costs.

The Challenge of AI Hallucinations

One important consideration when using generative AI is its tendency to “hallucinate”—a phenomenon where large language models (LLMs) generate patterns, objects, or information that do not exist, often resulting in inaccurate, misleading, or nonsensical outputs. This poses a significant challenge in high-stakes industries where precision and reliability are critical.

However, today’s LLMs were not designed with absolute accuracy as their primary objective. Their fundamental purpose is to generate—to create. No matter how sophisticated they become, there will always be limitations that prevent them from solving certain challenges, even if those challenges are theoretically solvable.

At their core, LLMs function as hyper-advanced autocomplete tools. They are trained to predict what should come next in a sequence, such as a string of text. If a model’s training data is rich in a particular subject, it may produce accurate and relevant outputs. However, LLMs are designed to always provide a response, even when the topic falls outside their training data, which can lead to incorrect or misleading results.

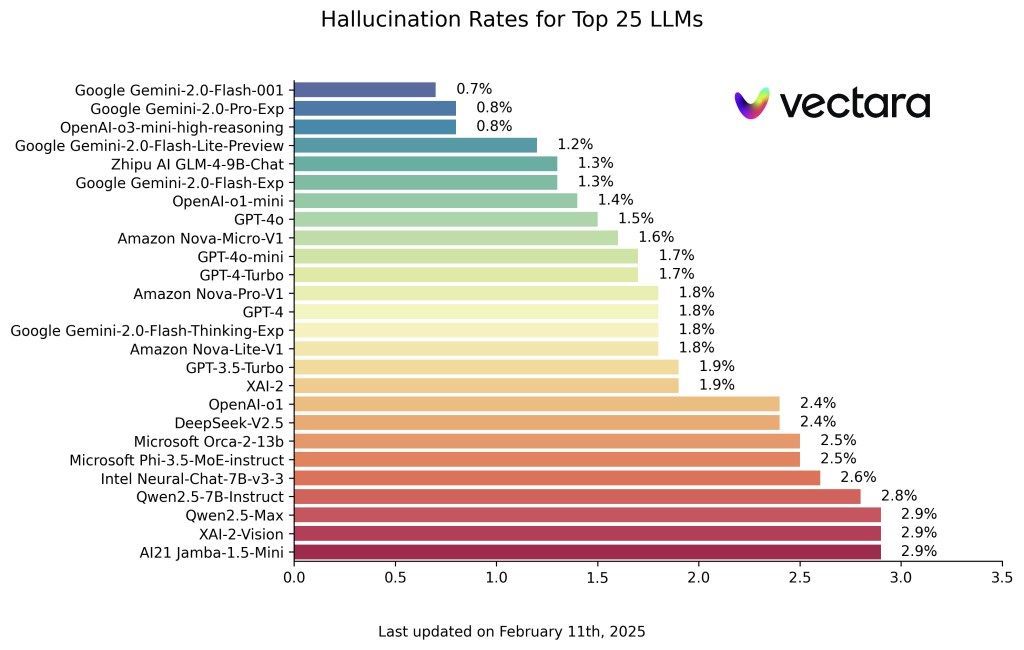

Vectara, a Palo Alto AI Agent company, tracks hallucination rates among large language models (LLMs) using its Hughes Hallucination Evaluation Model, maintaining a regularly updated leaderboard to compare performance. As of February 11, 2025, the leaderboard reflected the latest rankings.

The accompanying chart at this link shows hallucination rates ranging from 0.7% to 29.9%, highlighting the varying degrees of accuracy and reliability across different models.

Reducing AI Hallucinations: Strategies for More Reliable Outputs

While AI hallucinations cannot be completely eliminated, several strategies can help mitigate their impact and improve the reliability of AI-generated content:

– Use High-Quality Training Data – Generative AI models rely heavily on input data, meaning the quality and relevance of training datasets directly shape their behavior and accuracy. As the saying goes, garbage in, garbage out. Ensuring AI is trained on well-curated, diverse, and high-quality data can significantly reduce the likelihood of hallucinations.

– Rigorously Test and Continuously Monitor AI Models – Thorough pre-deployment testing is essential for identifying potential hallucinations before an AI model is put into use. Ongoing monitoring and evaluation help detect inconsistencies, allowing for refinements that improve accuracy over time.

– Establish Constraints and Filtering Mechanisms – AI models often hallucinate due to a lack of defined boundaries that limit possible outputs. Implementing rule-based expert systems, filtering tools, domain-specific guidelines, or probabilistic thresholds can enhance result consistency and accuracy. By integrating a rule-based expert system, organizations can enforce stricter guardrails around generative AI outputs.

Ensure Human Oversight – A crucial safeguard against AI hallucinations is human validation and review. Human oversight acts as a final quality checkpoint, catching errors and correcting inaccuracies. Subject matter experts can further refine AI-generated content by assessing its accuracy and contextual relevance. Incorporating a rule-based expert system as an additional layer of control helps ensure AI remains aligned with specific business needs and industry requirements.

By leveraging these strategies, organizations can significantly improve the reliability of generative AI while minimizing the risks associated with AI hallucinations.

Understanding Symbolic AI and Its Role in Expert Systems

Symbolic AI is a branch of artificial intelligence that represents knowledge and relationships between concepts using symbols and structured logic. Unlike machine learning, which relies on data-driven pattern recognition, symbolic AI applies explicit rules and logical reasoning to process information and make decisions.

Expert Systems: A Core Application of Symbolic AI

One of the earliest and most successful applications of symbolic AI is expert systems. These systems are designed to replicate human expertise in specific domains such as medicine, finance, engineering, and manufacturing.

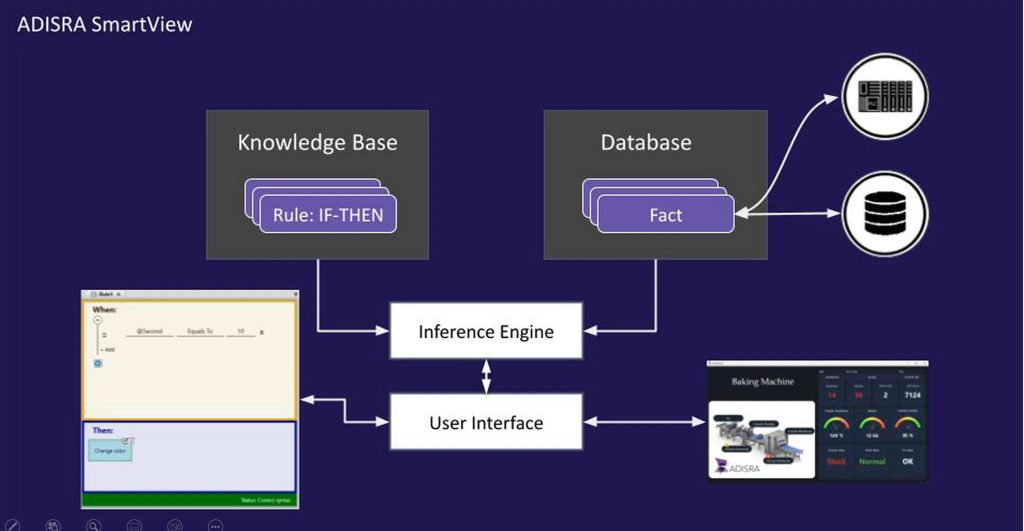

An expert system typically consists of two main components:

Knowledge Base – Stores domain-specific knowledge, including facts, rules, and relationships.

Inference Engine – Uses logical rules to analyze the knowledge base and draw conclusions, making expert systems valuable decision-support tools.

Production Rules: The Backbone of Symbolic AI Reasoning

A fundamental method of knowledge representation in symbolic AI is the use of production rules, also known as if-then rules or condition-action rules. These structured rules define specific actions or conclusions based on given conditions, forming the foundation of reasoning in expert systems.

Production rules typically consist of two components:

Antecedent (IF condition) – Defines the conditions that must be met for the rule to be triggered. This often involves facts, relationships, or sensor data.

Consequent (THEN action) – Specifies the actions to be executed, conclusions to be drawn, or adjustments to be made when the antecedent is met.

Symbolic AI in Industrial Automation

Production rules are widely used across industries, particularly in manufacturing, where they capture the expertise of plant engineers, machine builders, and quality assurance professionals. Symbolic AI enables HMI/SCADA systems to make real-time, rule-based decisions that enhance operational efficiency.

Example Applications in Industrial Automation:

Real-Time Environmental Monitoring – The HMI/SCADA system continuously tracks temperature, humidity, and airflow in server rooms.

Rule Example: If temperature > 27°C in any zone, then activate additional cooling units.

Power Usage Optimization – Adjusting equipment operation based on energy consumption trends.

Predictive Maintenance – Identifying potential machine failures before they occur.

Automated Alerts and Responses – Triggering alarms and actions based on operational thresholds.

Regulatory Compliance – Ensuring adherence to safety and environmental regulations.

Advantages of Expert Systems in Industrial AI

Expert systems offer a modular and flexible approach to knowledge representation, allowing for:

Easy Modifications – New rules can be added or modified without disrupting the entire system.

Transparency in Decision-Making – Rule-based logic ensures clarity and interpretability.

Scalability and Adaptability – Systems can evolve with industry requirements without extensive retraining.

By integrating symbolic AI and production rules, industrial automation systems can enhance decision-making, improve efficiency, and drive intelligent automation across various sectors.

The Role of Data in Industrial Automation

Industrial automation has always been a data-driven field, covering the entire process from raw material acquisition to the shipment of finished products. Every stage generates an enormous volume of data, and with the increasing adoption of digitalization and connectivity, the amount of data being collected has grown exponentially.

HMI and SCADA: The Backbone of Data Collection

Human-Machine Interface (HMI) and Supervisory Control and Data Acquisition (SCADA) systems are essential in industrial automation for gathering and managing operational data.

HMI Systems—Provide operators with a visual interface to monitor and control machinery, processes, and systems in real-time. HMIs facilitate interaction between humans and machines, allowing for seamless data entry and feedback.

SCADA Systems – Aggregate and analyze data from multiple sensors and control points across a facility, enabling centralized monitoring, control, and analysis of industrial processes. These systems ensure that data is captured, stored, and made available for deeper insights.

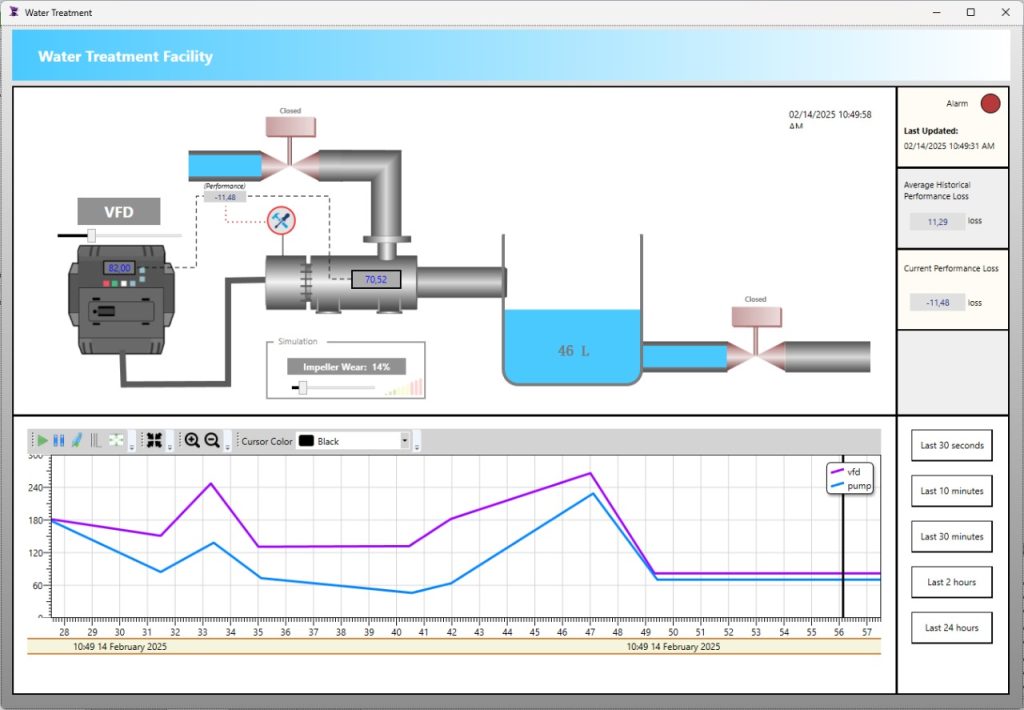

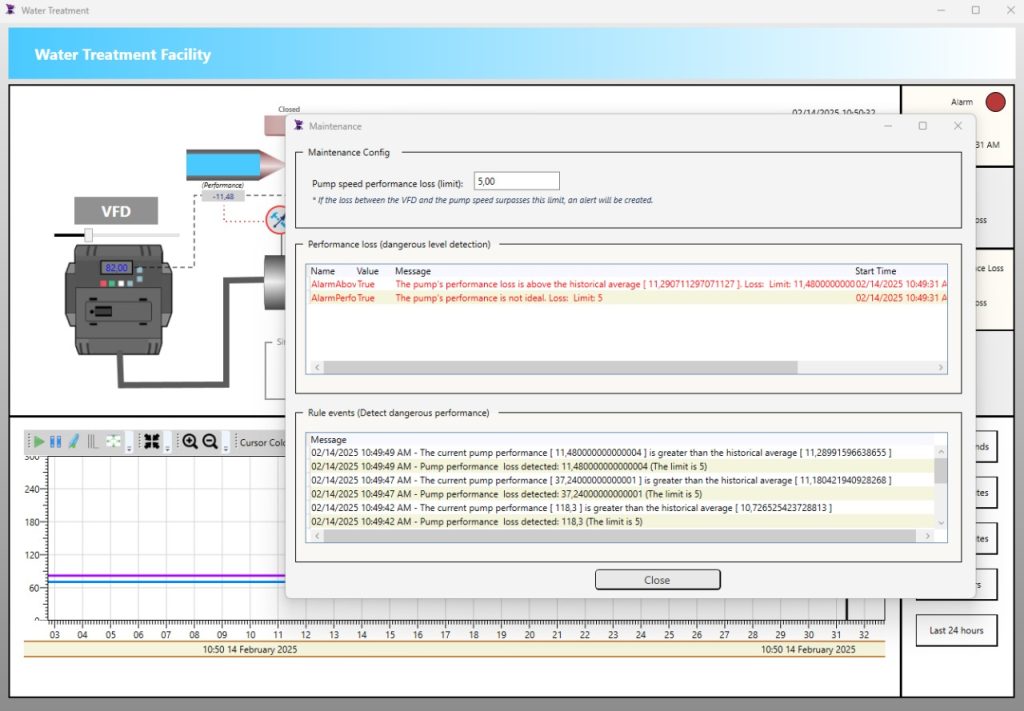

Enhancing Automation with a Rule-Based Expert System

Integrating HMI and SCADA systems with a rule-based expert system creates a highly efficient and intelligent automation environment. A rule-based expert system applies predefined logical rules to automate decision-making, ensuring operational consistency and compliance with industry standards.

ADISRA SmartView: Intelligent Decision-Making with Expert Systems

ADISRA SmartView, equipped with an integrated rule-based expert system, enhances industrial automation by applying predefined rules to real-time data. These rules, based on industry expertise, best practices, and regulatory requirements, enable smarter automation by:

– Automatically triggering alarms in response to critical conditions.

– Initiating corrective actions to prevent failures and optimize performance.

– Predicting potential failures before they occur, improving system reliability, and reducing downtime.

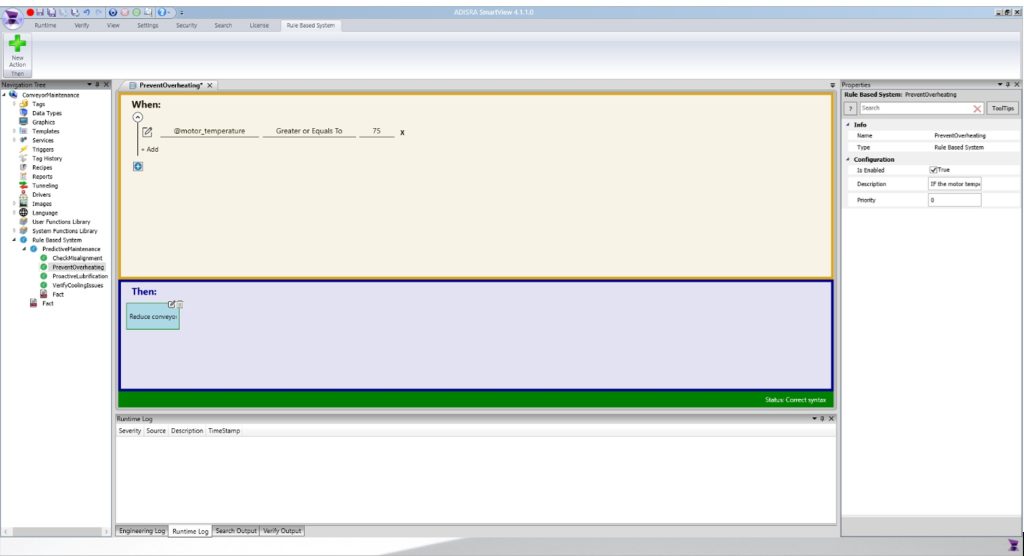

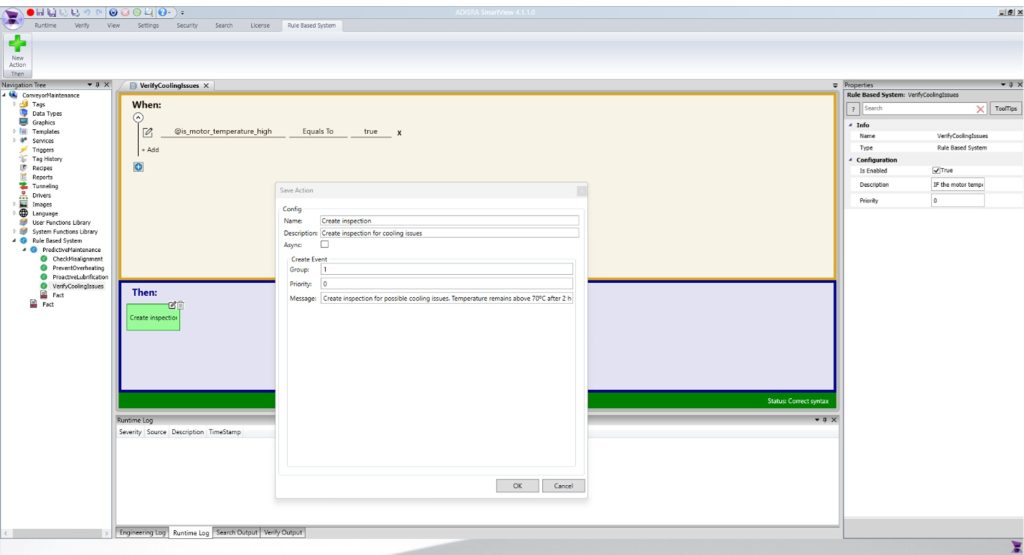

Example: Predictive Maintenance Rule in ADISRA SmartView

Consider the impact of prolonged high temperatures on industrial components such as belts, rollers, and seals. Excessive heat can cause materials to expand, warp, or degrade, leading to misalignment, belt slippage, or even complete system failure. A rule-based expert system in ADISRA SmartView can proactively address this issue:

Rule Example:

IF the motor temperature exceeds 70°C for more than 2 hours, THEN schedule an inspection for potential cooling system issues.

This rule can be seamlessly implemented within ADISRA SmartView’s rule-based expert system, allowing for real-time monitoring and proactive maintenance scheduling.

With ADISRA SmartView, industries can achieve a new level of efficiency by harnessing the power of HMI/SCADA and expert systems, which deliver real-time insights, proactive maintenance, and optimized industrial operations.

Experience ADISRA SmartView by downloading a software trial from our website here.

Conclusion: The Evolving Role of AI in Industrial Automation

As artificial intelligence continues to advance, its applications in industrial automation are becoming more sophisticated, improving efficiency, decision-making, and system reliability. While AI is often portrayed in films and literature as highly cognitive or even sentient, the reality is that today’s AI models—whether deep learning, generative AI, or rule-based expert systems—are powerful tools designed to enhance specific tasks rather than replicate human intelligence.

Neural networks and deep learning have enabled significant progress in fields such as image recognition, predictive maintenance, and automation, while generative AI is transforming content creation, engineering, and design. However, challenges such as AI hallucinations highlight the importance of structured data, rigorous testing, and human oversight to ensure reliability.

In industrial environments, rule-based expert systems provide a structured approach to AI-driven decision-making, particularly when integrated with HMI/SCADA systems. Solutions like ADISRA SmartView combine real-time monitoring, data visualization, and automated rule-based logic to optimize operations, reduce downtime, and improve safety.

As AI continues to evolve, industries must strike a balance between innovation and control—leveraging AI’s capabilities while implementing safeguards to ensure accuracy, efficiency, and compliance. By integrating symbolic AI, deep learning, and expert systems, industrial automation can move toward a smarter, more resilient future.

Try ADISRA SmartView today by downloading a free trial from our website here.

ADISRA®, ADISRA’s logo, InsightView® and KnowledgeView® are registered trademarks of

ADISRA, LLC.

Copyright

© 2025 ADISRA, LLC. All Rights Reserved.