I am always fascinated when I hear from customers about the innovative ways they are using ADISRA SmartView in their industrial applications. Every story offers a unique glimpse into how our software helps solve real-world challenges, often in ways we had not even anticipated. One area that continues to evolve is integrating vision systems, computer vision, and machine learning libraries. It is a powerful combination, transforming how manufacturers approach quality control, process optimization, and predictive maintenance. This week’s blog delves into the topic of vision systems, exploring how they are being utilized alongside HMI/SCADA platforms, such as ADISRA SmartView, and current industry trends, as well as the growing market opportunities this integration is unlocking.

What is Machine Vision in Industrial Automation?

Machine vision is a technology that leverages computer vision and image processing to enable machines to perceive and interpret visual information, much like human perception but with greater consistency and speed. By capturing images through cameras or sensors and analyzing them with specialized algorithms and software, machine vision systems can identify patterns, measure dimensions, detect defects, and guide actions based on the observations they make.

In industrial automation, machine vision plays a role in automating tasks that once relied heavily on manual inspection. It is most commonly used for high-speed, high-precision applications such as:

Dimensional Verification: Ensuring that parts meet exact size and shape specifications before moving on to assembly.

Position Detection: Determining the exact location and orientation of parts on a conveyor so robotic systems can pick and place them accurately.

Defect Detection: Spotting scratches, dents, or missing components so flawed products can be removed before entering the next phase of production.

By integrating machine vision with HMI/SCADA platforms like ADISRA SmartView, manufacturers can create intelligent systems that not only monitor and control processes but also visually perceive what’s happening in real-time and respond accordingly.

The Expanding Role and Market of Machine Vision Systems

Machine vision systems are at the heart of modern industrial automation, serving as the digital “eyes” of production. These systems comprise interconnected devices, including cameras, sensors, and processing units, that automatically guide manufacturing operations by analyzing images in real-time. Whether it is a static part waiting for assembly or a fast-moving item on a conveyor, machine vision utilizes digital imagery and intelligent algorithms to make informed decisions, enabling tasks such as go/no-go assessments, defect detection, and precise part positioning.

Typical applications for machine vision include:

– Quality Assurance & Inspection – Catching defects, verifying completeness, and ensuring product conformity before the following process.

– Positioning & Guidance – Helping robots pick, place, or interact with components by identifying their location and orientation.

– Measurement & Identification – Performing high-speed, high-precision measurements and barcode or part recognition.

– Predictive Maintenance – Monitoring equipment conditions visually to predict and prevent failures before they happen.

Market Momentum

The machine vision market is experiencing robust growth. It’s projected to rise from $19.59 billion in 2024 to $21.27 billion in 2025, with a compound annual growth rate (CAGR) of 8.6%, and it is forecasted to reach $32.66 billion by 2029. This growth reflects the increasing adoption of the technology across industries that seek more intelligent automation and higher production standards.

Similarly, robotic vision, which enables robots to “see” through a combination of calibrated cameras, algorithms, and sensors, is also on the rise. The robotic vision market is expected to grow from $2.53 billion in 2024 to $2.76 billion in 2025, reaching $4.09 billion by 2029.

Even more specific is the industrial machine vision camera market, which focuses on the imaging hardware used in manufacturing and inspection. It is projected to grow from $11.63 billion in 2024 to $13.52 billion in 2025, with estimates climbing to $23.83 billion by 2029.

What is Driving This Growth?

Several key factors are fueling the rapid expansion of machine vision technology:

– Automation & Robotics – As factories become more autonomous, the need for intelligent visual systems that can operate without human oversight is accelerating.

– Demand for Precision & Quality – Industries require increasingly stringent quality control, and vision systems are essential to meeting these standards.

– Technological Advancements – Breakthroughs in artificial intelligence, machine learning, high-resolution imaging, and processing power are making vision systems faster, smarter, and more cost-effective.

Emerging Trends to Watch

– AI and Machine Learning Integration

Vision systems are increasingly leveraging AI to go beyond basic inspection, enabling predictive analytics, anomaly detection, and adaptive learning. Later in this blog, we will explore a real-world application that utilizes ADISRA SmartView and AI for real-time quality control using machine learning models.

– Edge Computing for Real-Time Response

Edge devices are now capable of processing vision data on-site, dramatically reducing latency and enabling real-time decision-making without needing to send everything to the cloud.

– 3D Vision Technology

As industries shift toward greater complexity in automation, 3D vision is becoming increasingly essential for applications such as robotic picking, precision assembly, and detailed 3D inspections.

– Event-Based Imaging

Inspired by biological vision systems, event-based imaging captures changes in a scene rather than recording entire frames. This approach reduces data processing requirements and improves response times, making it ideal for high-speed industrial applications.

Traditional Vision Systems in Industrial Automation

Many of our customers are successfully integrating ADISRA SmartView with industry-standard vision systems, such as those from Cognex, a leader in machine vision technology. Cognex systems are widely used to automate key manufacturing tasks, such as part inspection, defect detection, assembly verification, and robotic guidance, all based on computer vision.

In a typical setup, the Cognex In-Sight vision system communicates with ADISRA SmartView using Modbus TCP, leveraging a feature called In-Sight Display Control (CvsInSightDisplay). This control enables the direct transmission of inspection results, such as pass/fail status, defect counts, or measurement data, to the SCADA system. ADISRA SmartView then visualizes this information on the user interface using a .NET control, which can even display live images from the vision camera directly on the screen.

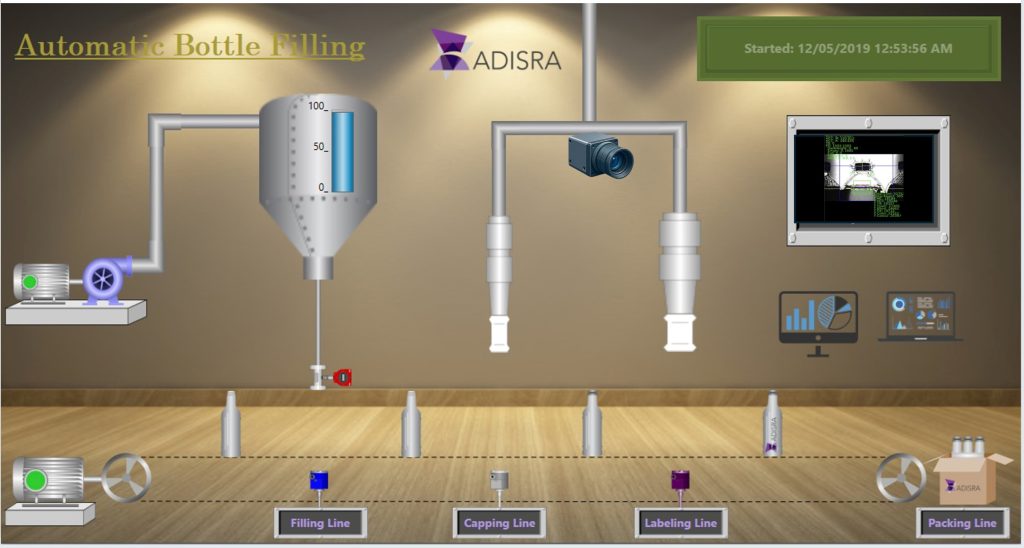

One real-world example comes from a bottling plant application, where high-speed filling lines include multiple dispensing heads operating simultaneously. These systems must dispense precise volumes without spillage, even at fast production rates. In this case, a plant supervisor required real-time visibility into all production lines to enhance uptime, minimize inefficiencies, and ensure that production remained on schedule.

Here, the Cognex vision system was used to verify that bottles were correctly filled, properly sealed, and labeled with the correct information. Any issues, like a missing cap or misaligned label, were immediately detected and communicated to ADISRA SmartView. From there, ADISRA SmartView would alarm operators, log defect rates, and trigger maintenance alerts. When paired with its built-in rule-based expert system, ADISRA SmartView could also evaluate whether processes were running within acceptable thresholds set by engineers or production specialists.

This type of traditional vision system integration remains a foundational element of quality assurance and operational monitoring in manufacturing environments. But as we’ll explore in the next section, the rise of artificial intelligence is dramatically expanding the capabilities of these systems, bringing new levels of intelligence and automation to industrial vision applications.

AI-Powered Vision: A Glimpse Into the Future

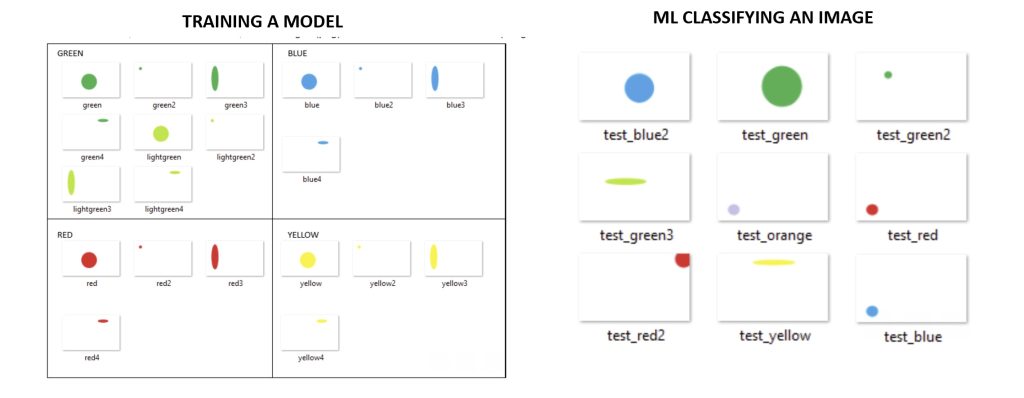

As powerful as traditional vision systems are, the integration of artificial intelligence and machine learning is unlocking a new frontier in industrial automation. At ADISRA, our engineering team recently developed a proof of concept (POC) demonstrating how ADISRA SmartView can be integrated with OpenCV and scikit-learn (sklearn) to create an AI-enhanced vision system.

OpenCV, an open-source computer vision library, is widely used for real-time image processing. Scikit-learn, one of Python’s most popular machine learning libraries, provides efficient tools for data modeling and classification. By combining these technologies with ADISRA SmartView’s intuitive interface and User Functions, our team created a simple yet effective demo that showcases the potential of ML-driven vision.

In the POC, ADISRA SmartView called a custom User Function to load and classify image files for training a basic machine learning model. The model was taught to recognize shapes and colors, specifically green, red, blue, and yellow objects, in various formats. Once trained, the system could automatically classify new images based on these visual features.

This approach opens up exciting possibilities, such as vision systems that not only detect defects but also learn from examples, adapt over time, and make more informed decisions in real-time. The result is a more intelligent, more flexible, and more responsive vision solution that brings the full power of industrial AI into the hands of manufacturers.

Conclusion: From Eyes to Insight

Machine vision has long been a key enabler of automated inspection, quality assurance, and robotic guidance. Integrating vision systems, such as Cognex, with ADISRA SmartView enables operators to gain real-time insights and control, ensuring that production runs efficiently and consistently.

With AI-driven tools like OpenCV and scikit-learn, manufacturers can now go beyond simple detection and evolve toward intelligent, self-optimizing systems. Whether it is a bottling plant monitoring cap placement or a pick-and-place robot adjusting for visual variations, the fusion of vision and machine learning is transforming how we see industrial automation.

Ready to take your vision system to the next level?

Start integrating with ADISRA SmartView today and unlock the full potential of intelligent, real-time automation.

Download now and experience smarter control, smarter insights, and smarter decisions.

Cognex Corporation® and In-Sight® are registered trademarks of Cognex Corporation

ADISRA®, ADISRA’S logo, InsightView®, and KnowledgeView® are registered trademarks of

ADISRA, LLC.

© 2025 ADISRA, LLC. All Rights Reserved.