In today’s hyper-competitive global market, efficiency, quality, and customer satisfaction are no longer aspirational; they are essential for survival. Organizations striving to deliver more value at greater speed are turning to Lean Six Sigma as a proven framework for operational excellence, continuous improvement, and sustainable growth.

But 2025 is not business as usual. With the increased complexity resulting from digital transformation, mounting environmental responsibilities, and evolving customer demands, Lean Six Sigma must also evolve. That is where modern tools like ADISRA InsightView come in, turning data into insight and strategy into measurable results.

What Is Lean Six Sigma?

Developed in the 1980s by Mikel Harry and Bill Smith at Motorola, Six Sigma was initially a statistical approach to reducing defects and improving quality. Over time, it has grown into a full-fledged management philosophy centered around the DMAIC methodology:

– Define the problem

– Measure current performance

– Analyze data to identify root causes

– Improve the process

– Control to sustain improvements

When combined with Lean Manufacturing, which focuses on eliminating waste and maximizing customer value, the result is Lean Six Sigma. This robust hybrid framework reduces variation, cuts waste, and boosts speed and efficiency.

Why Lean Six Sigma Is More Relevant Than Ever in 2025

1. Digital Complexity Requires Smarter Simplification

As companies modernize, digital initiatives often introduce unintended complexity, data silos, workflow redundancies, and new bottlenecks. One manufacturer uncovered millions in hidden waste when Lean Six Sigma was used to assess digital inefficiencies. In the modern landscape, inefficiencies are increasingly found in the data, not just the machinery.

2. Customers Demand Speed—Without Sacrificing Quality

Zero-defect expectations and rapid delivery cycles are the new norm. Lean Six Sigma enables companies to meet these demands through continuous improvement and tight process control, achieving speed and quality without trade-offs.

3. Sustainability Is Now a Business Imperative

Facing tighter environmental regulations, many companies are using Lean Six Sigma principles to redefine “waste”, including energy use and emissions. The result is smaller footprints, lower costs, and greater regulatory compliance.

Top Lean Six Sigma Trends in 2025

1. Integration with AI and Machine Learning

Modern Lean Six Sigma initiatives are supercharged by AI and ML technologies:

– AI-powered sensors and IoT devices provide real-time production and supply chain data

– ML algorithms detect anomalies, predict failures, and reveal hidden inefficiencies

– Automation handles repetitive tasks, freeing teams for higher-level problem-solving

– Predictive analytics moves the DMAIC “Control” phase from reactive to proactive

InsightView integrates seamlessly into this ecosystem, offering real-time dashboards, anomaly detection, and root cause analysis that accelerate the entire improvement cycle.

2. The Rise of Green Lean Six Sigma (GLSS)

According to Deloitte, 70% of business leaders in 2024 expect climate change to have a significant impact on their operations over the next three years. Green Lean Six Sigma (GLSS) adds sustainability metrics into Lean Six Sigma initiatives, tracking and improving:

– Energy consumption

– Water usage

– Emissions

– Material waste

InsightView empowers this transformation. With built-in energy monitoring and analytics tools, manufacturers can align continuous improvement with climate goals and regulatory compliance.

3. Data-Driven Decision Making at Scale

Big data is here to stay, and Lean Six Sigma’s data-driven foundation is more valuable than ever. With real-time monitoring, historical trends, and predictive forecasting, teams can act faster, validate decisions, and scale improvements across global operations.

InsightView supports this evolution with intuitive dashboards, customizable KPIs, and analytics tools that turn raw data into actionable strategy.

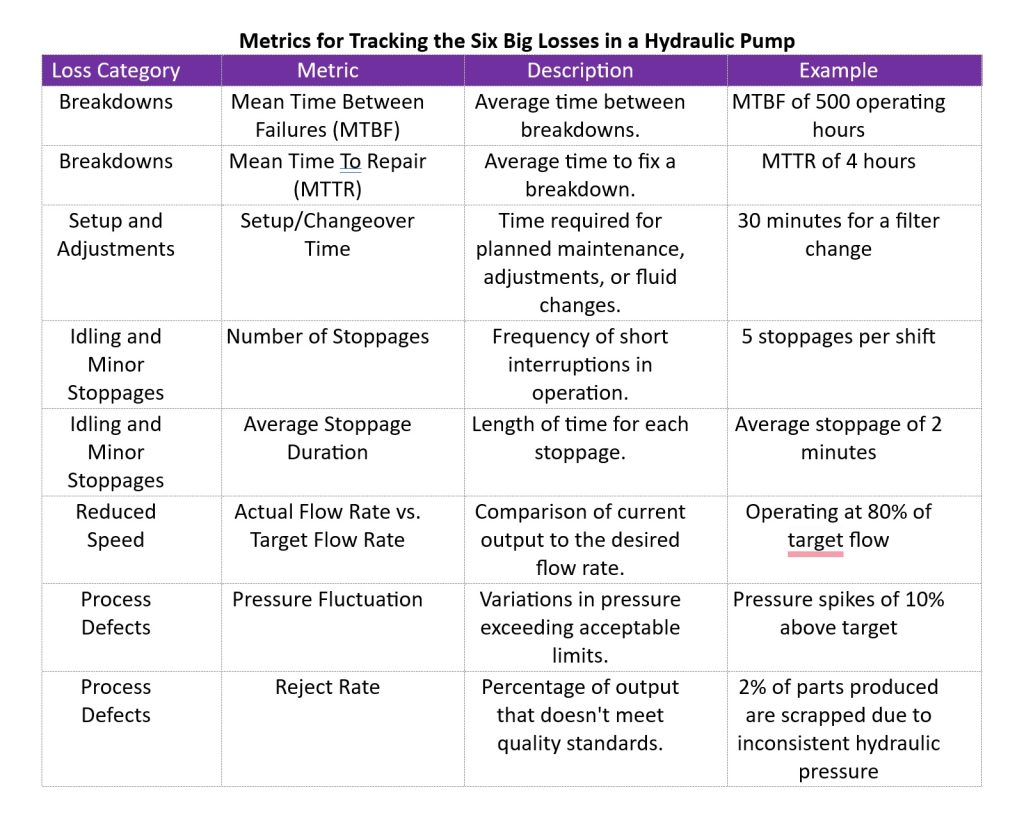

Lean Six Sigma, OEE, and the Six Big Losses

Lean Six Sigma and Overall Equipment Effectiveness (OEE) go hand in hand. OEE measures manufacturing productivity by determining the percentage of planned production time that is productive. But for more profound insight, companies turn to the Six Big Losses, the root causes of performance loss:

– Equipment failures

– Setup and adjustment delays

– Idling and minor stops

– Reduced speed

– Startup rejects

– Production rejects

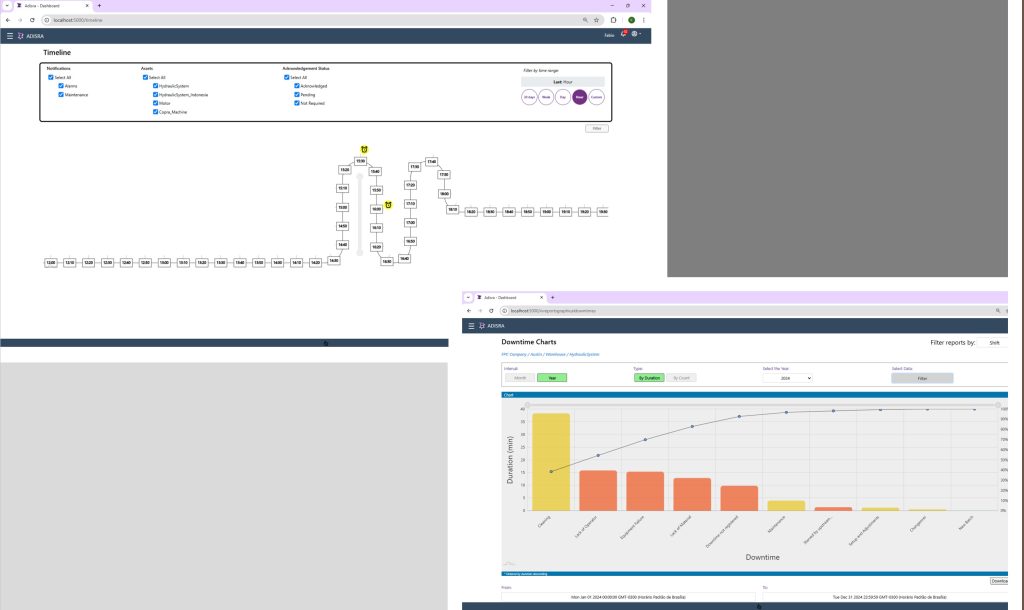

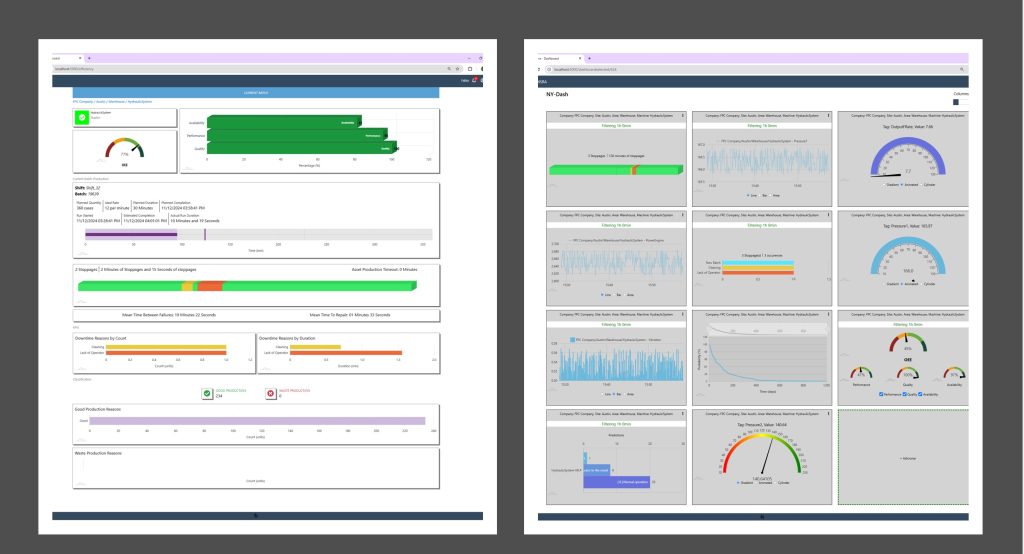

InsightView makes these losses visible in real time. Its customizable dashboards allow manufacturers to:

– Monitor machine and line performance

– Pinpoint inefficiencies

– Set benchmarks

– Execute countermeasures faster

By providing both high-level KPIs and granular diagnostics, InsightView equips Lean Six Sigma and TPM teams to take data-driven action where it matters most.

Custom Dashboards and Cross-Plant Visibility

Whether you manage a single facility or a global network, InsightView provides scalable visibility across machines, lines, and plants. Teams can:

– Customize dashboards by role or responsibility

– Compare KPIs across regions or product lines

– Benchmark performance and allocate resources efficiently

– Access insights via desktop, tablet, or mobile

This cross-plant capability is essential for standardizing Lean Six Sigma practices and accelerating enterprise-wide improvement.

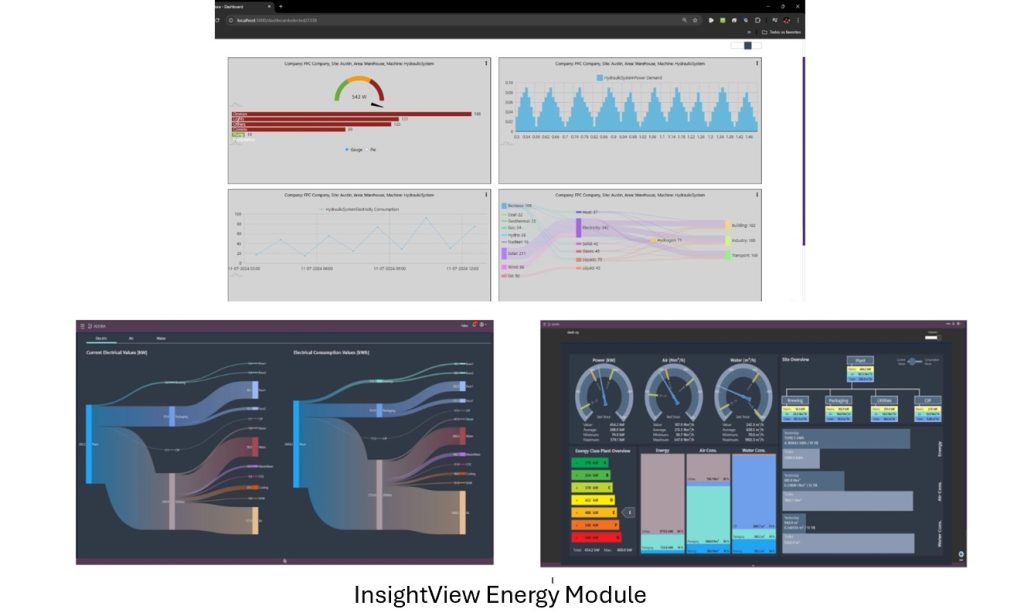

Energy Intelligence: The Next Frontier in Sustainability

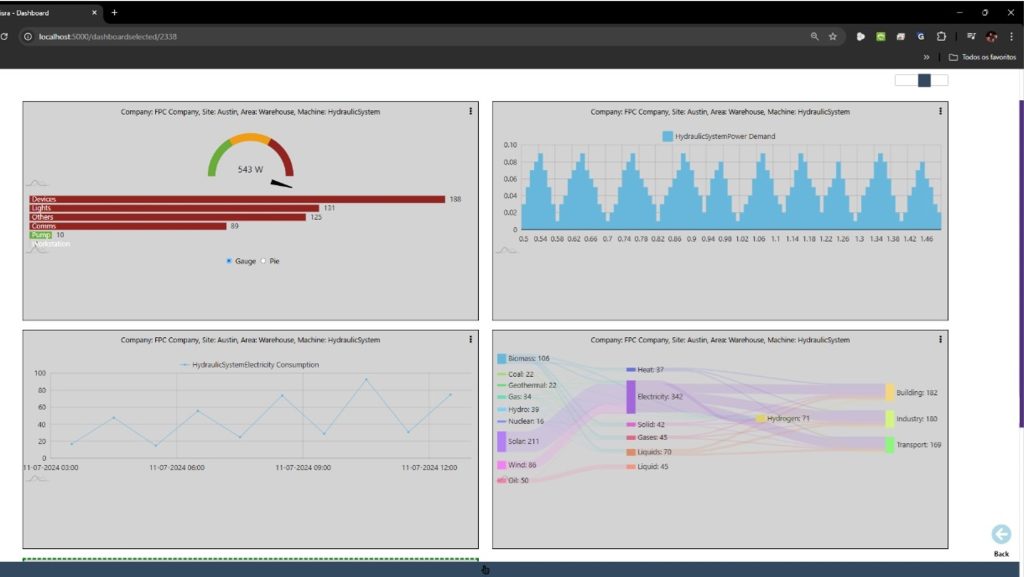

Sustainability is not a side project; it is a strategic priority. InsightView’s Energy Management Module empowers manufacturers to:

– Track energy usage by line, shift, or site

– Identify inefficiencies and cost drivers

– Align operations with sustainability targets

– Meet evolving regulatory requirements

This module also promotes transparency and accountability. With clear metrics, companies can report progress to stakeholders, demonstrate environmental stewardship, and improve the bottom line.

Conclusion: The Future of Operational Excellence

As we look ahead to 2025 and beyond, Lean Six Sigma has evolved into a strategic imperative, a vital toolset for navigating change, driving innovation, and achieving operational resilience.

Whether you are digitizing operations, accelerating time-to-market, or striving for net-zero emissions, Lean Six Sigma, enhanced by tools like InsightView, provides a competitive edge.

By equipping teams with real-time insights, visual dashboards, and sustainability analytics, InsightView transforms Lean Six Sigma from theory to action. In the short term, it surfaces inefficiencies and performance gaps. In the long term, it guides targeted, sustainable improvements across the enterprise.

In an era defined by complexity, speed, and accountability, organizations that embrace Lean Six Sigma and deploy modern tools like InsightView will be the ones that thrive.

Want to experience InsightView for yourself? Request an account here.

Want a private webinar on any of these products? Request the webinar here.

Have questions or feedback? We are here to help! Feel free to contact us at info@adisra.com; we would love to hear from you.

For additional insights into ADISRA’s InsightView and KnowledgeView, we invite you to explore these previous blog posts.

OEE in 2025: From KPI to AI-Driven Optimization

The High Cost of Unplanned Downtime and Why Predictive Maintenance is the Solution

Maximizing Productivity and Sustainability: The Critical Role of Energy Management in Manufacturing

Tackling the Six Major Losses to Maximize OEE in 2025

Enhancing Hydraulic System Performance From Real-Time Monitoring to Predictive Maintenance

Join Us for a Live Webinar!

Join us on July 24th at 9:30 AM CDT for an exclusive webinar highlighting the latest features and enhancements in ADISRA SmartView V4.1.3. Discover how these upgrades can help you build automation solutions that are faster, smarter, and more connected than ever before.

Register here to secure your spot.

At the end of the session, we will host a live Q&A, providing you with the opportunity to ask the ADISRA team any questions you may have about SmartView, including new features, best practices, or project-specific challenges. We are here to support your success.