Overall Equipment Effectiveness (OEE) is a fundamental key performance indicator (KPI) in manufacturing that measures the effectiveness of a production operation. It is calculated by multiplying three core factors: Availability, Performance, and Quality. Software tools like ADISRA InsightView help manufacturers monitor and analyze these dimensions in real time, enabling continuous improvement and process optimization.

Modern OEE software capabilities include:

- Availability, performance, and quality calculations

- Real-time equipment monitoring

- Root cause analysis of downtime and inefficiencies

- Predictive analytics for early issue detection

ADISRA SmartView and ADISRA InsightView support these OEE metrics, both on-premises and in the cloud, providing manufacturers with flexible deployment options to suit their infrastructure and operational goals.

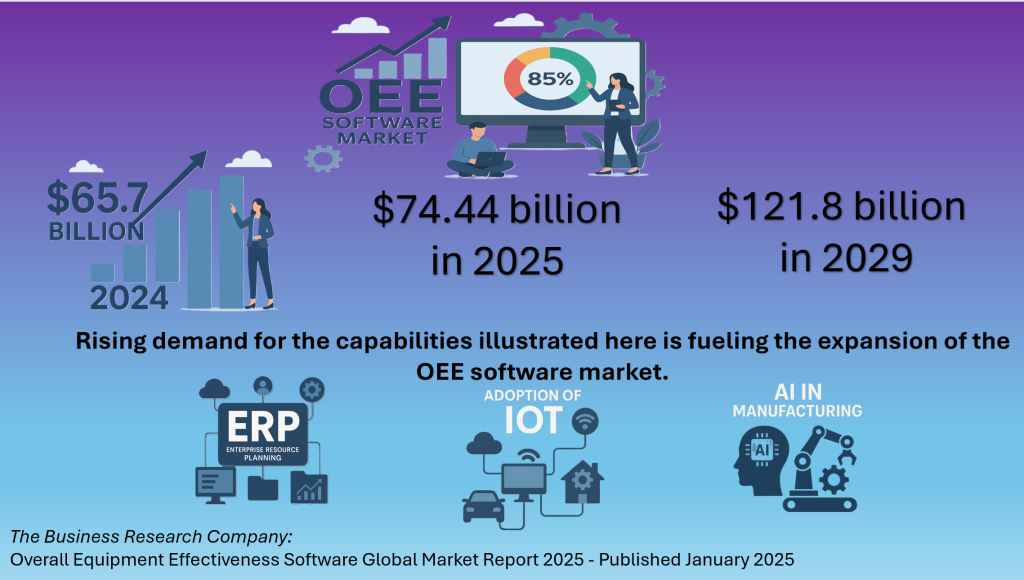

According to The Business Research Company, the global OEE software market is experiencing rapid growth, rising from $65.7 billion in 2024 to $74.44 billion in 2025, and projected to reach $121.18 billion by 2029. This growth is driven by the integration of ERP systems, widespread adoption of IoT and AI in manufacturing, increased automation, and the growing emphasis on productivity and equipment optimization.

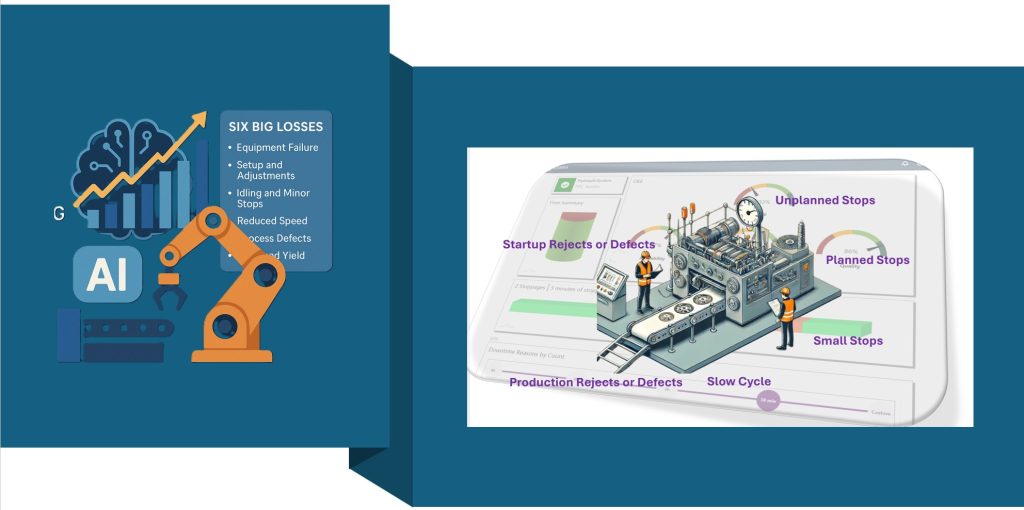

OEE is no longer just a passive measurement of performance; it is becoming a proactive tool for digital transformation. In 2025, with AI and predictive analytics gaining traction, manufacturers are transitioning from reactive tracking to AI-augmented optimization. This shift enables real-time identification and elimination of the Six Major Losses, driving efficiency, minimizing unplanned downtime, and enabling smarter, more adaptive operations.

To dive deeper into OEE and the Six Major Losses, check out our previous blog post.

AI’s Role in Redefining OEE and Eliminating the Six Big Losses

Artificial Intelligence (AI) is revolutionizing how manufacturers optimize OEE and tackle the Six Big Losses in discrete manufacturing. By delivering advanced analytics, real-time insights, and intelligent automation, AI transforms OEE from a reactive measurement into a dynamic optimization engine.

AI enhances OEE by:

- Continuously analyzing real-time data to detect inefficiencies

- Predicting potential failures before they cause downtime

- Automating responses to common production issues

- Providing actionable insights to improve quality, speed, and uptime

This AI-driven approach empowers manufacturers to not only monitor performance but actively reduce waste, maximize asset utilization, and drive continuous improvement across all levels of production.

AI Optimization Across OEE Pillars: Availability, Performance, Quality

Artificial Intelligence (AI) is unlocking powerful new capabilities in discrete manufacturing, especially in enhancing the three core components of Overall Equipment Effectiveness (OEE): Availability, Performance, and Quality. By continuously collecting and analyzing vast amounts of production data, AI-powered tools offer deep operational insights and actionable recommendations to improve productivity, reduce waste, and drive intelligent decision-making.

Planned & Unplanned Downtime:

AI-based predictive maintenance solutions analyze sensor data to detect patterns and anticipate potential equipment failures before they occur. This proactive approach minimizes unexpected downtime, reduces maintenance costs, and maximizes asset availability.

ADISRA KnowledgeView delivers cloud-based predictive maintenance capabilities tailored for innovative manufacturing environments.

Setup and Changeovers:

AI can streamline setup and changeover procedures by learning from historical data and identifying optimal settings and sequences. This significantly reduces setup time and improves overall availability.

ADISRA SmartView, equipped with a built-in rule-based expert system, can encode plant-specific knowledge to automate and optimize setup routines.

Idling and Minor Stops:

AI-powered anomaly detection monitors real-time data to pinpoint the root causes of micro-stoppages, such as misfeeds, jams, or sensor errors. It can also correlate operating speeds with stoppage patterns to recommend optimal run conditions.

ADISRA InsightView and KnowledgeView work together to provide this level of detailed performance intelligence.

Reduced Operating Speed:

AI identifies trends and environmental factors that may be contributing to reduced machine speed, such as tool wear, material variability, or ambient temperature changes. With this knowledge, manufacturers can make proactive adjustments to maintain peak performance.

KnowledgeView helps predict and prevent such events before they impact production.

Production Rejects:

AI-integrated vision systems conduct real-time inspections with higher accuracy and consistency than manual checks. These systems detect defects early, reduce scrap, and improve final product quality. In a previous blog, we discussed how ADISRA SmartView integrates with vision systems and uses generative AI to classify product features, including subtle color variations.

Startup Rejects:

By analyzing historical startup data, AI can refine warm-up and ramp-up procedures to minimize defects produced during the initial phase of production.

InsightView and KnowledgeView together can model, simulate, and refine startup behavior for consistent quality from the start.

AI’s Overall Impact on OEE

Enhanced Data Accuracy:

AI automates data collection and analysis, eliminating errors from manual entry and ensuring reliable OEE metrics.

Predictive OEE:

Instead of reacting to problems, manufacturers can anticipate and prevent them using AI’s predictive insights into performance degradation, quality issues, or equipment wear.

Process Optimization:

Real-time AI algorithms dynamically guide operators, or they can adjust machine parameters and workflows to avoid bottlenecks and maintain optimal throughput.

Improved Product Quality:

AI continuously refines quality inspection criteria and processes to ensure consistent, high-quality outputs and minimize rework.

Cost Savings and Waste Reduction:

By reducing downtime, improving productivity, and minimizing defects, AI directly contributes to significant operational cost savings.

Real-Time Monitoring and Alerts:

Intelligent dashboards and alert systems notify teams of performance deviations, enabling fast and targeted corrective actions.

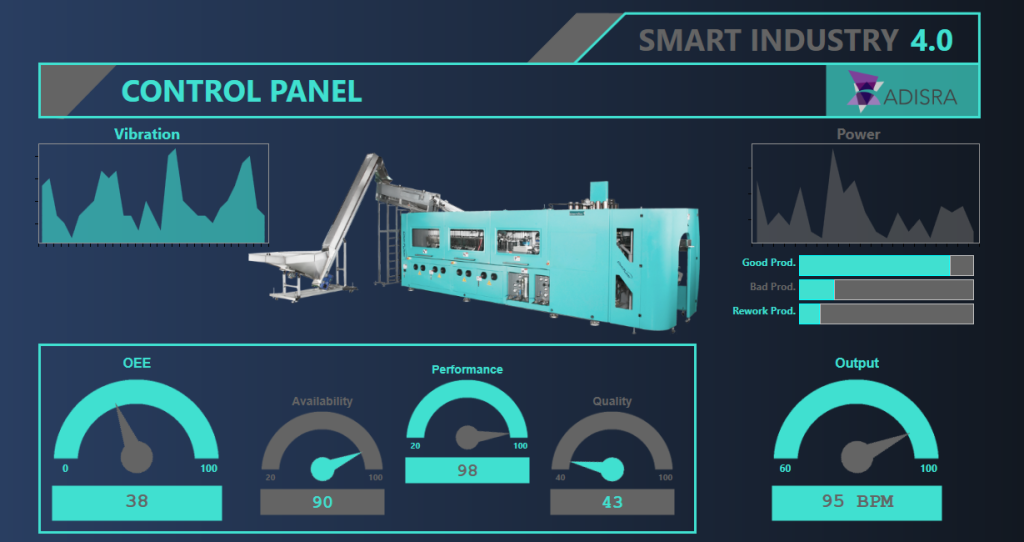

ADISRA SmartView: The Foundation for Intelligent OEE Monitoring

ADISRA SmartView is a powerful HMI/SCADA software platform designed to help manufacturers visualize, monitor, and control their operations with precision and flexibility. With the ability to create OEE applications (examples available here), real-time data collection, and rule-based automation, ADISRA SmartView serves as the foundation for intelligent manufacturing.

Key features include:

– Ability to create dashboards for real-time visibility into availability, performance, and quality

– Rule-Based Expert System to automate responses and optimize processes based on plant-specific knowledge

– Seamless Connectivity to PLCs, sensors, databases, and cloud platforms

– Scalable Architecture supporting both on-premises and hybrid cloud deployments

– Customizable Visualizations to adapt to any discrete manufacturing environment

– Ability to configure pre-defined modifications at run-time

When paired with InsightView and KnowledgeView, ADISRA SmartView becomes a central hub for proactive decision-making, predictive maintenance, and AI-enhanced production optimization.

Download ADISRA SmartView trial today.

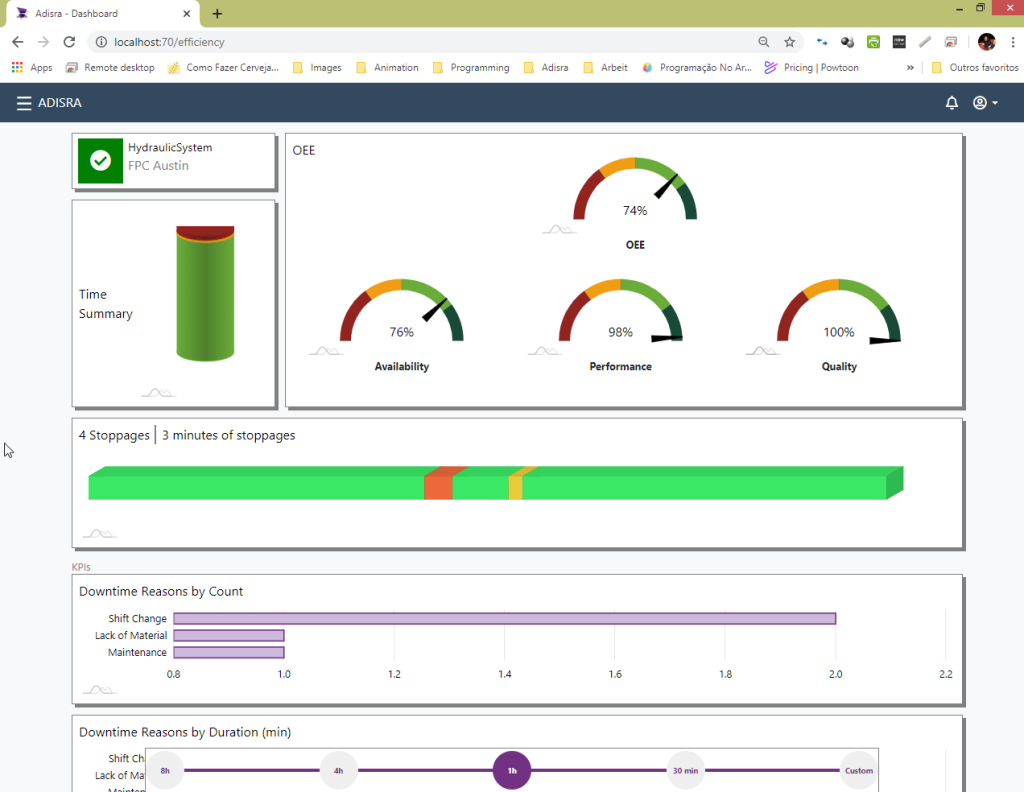

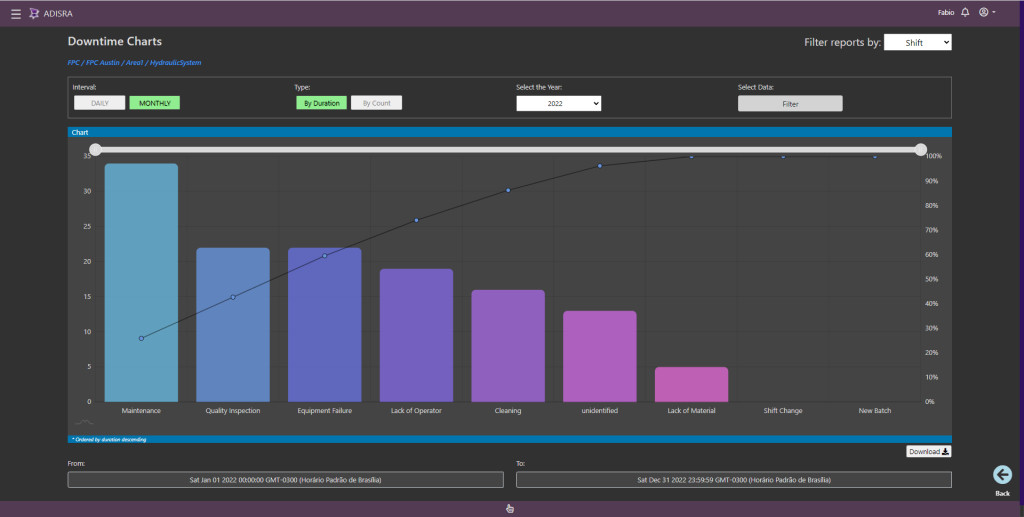

ADISRA InsightView: Real-Time Visibility for Productivity and Energy Efficiency

ADISRA InsightView is a powerful, cloud-enabled analytics and visualization platform designed to drive productivity and efficiency across manufacturing operations. By transforming raw data into actionable insights, InsightView helps users monitor machine and process performance in real time, calculating critical KPIs like Overall Equipment Effectiveness (OEE) and pinpointing the Six Big Losses that impact operational efficiency.

Highly customizable and intuitive, InsightView empowers manufacturers to build dashboards tailored to their specific needs and visualize performance data across machines, lines, and even entire facilities, all from a single, unified interface accessible from desktops, browsers, tablets, and mobile devices.

Cross-Plant Visibility and Enterprise Insights

Whether monitoring a single site or managing a network of global facilities, InsightView provides a comprehensive view of operations. Users can compare and analyze performance across companies, plants, processes, and equipment, enabling more intelligent decisions and continuous improvement throughout the entire production lifecycle.

Energy Management Module

With growing global focus on sustainability and renewable energy, InsightView’s Energy Management Dashboard helps organizations align with energy conservation goals and government-backed initiatives. This module supports real-time energy monitoring, resource optimization, and demand-supply balancing through cloud-based insights, empowering teams to reduce consumption, lower costs, and enhance environmental performance.

For more information about InsightView’s Energy Management Module, please read the previous blog here.

By combining production metrics with energy data, InsightView enables manufacturers to uncover hidden inefficiencies, reduce waste, and maximize both productivity and sustainability.

Key Features:

– Connectivity: Aggregates data from multiple local and remote sources into unified, actionable dashboards

– Customization: Drag-and-drop interface makes it easy to configure dashboards

– Visualization: Access insights from any device, whether desktop, browser, tablet, or mobile

– Reporting: Generate and export reports for team collaboration or record-keeping

– Security: Role-based access control ensures users see only the information relevant to their role

With ADISRA InsightView, manufacturers gain deep visibility into operations, illuminating not just machine performance but the entire product lifecycle. Whether optimizing OEE or managing energy usage, InsightView delivers the intelligence needed to make faster, smarter decisions.

Want to experience InsightView for yourself? Request an account here.

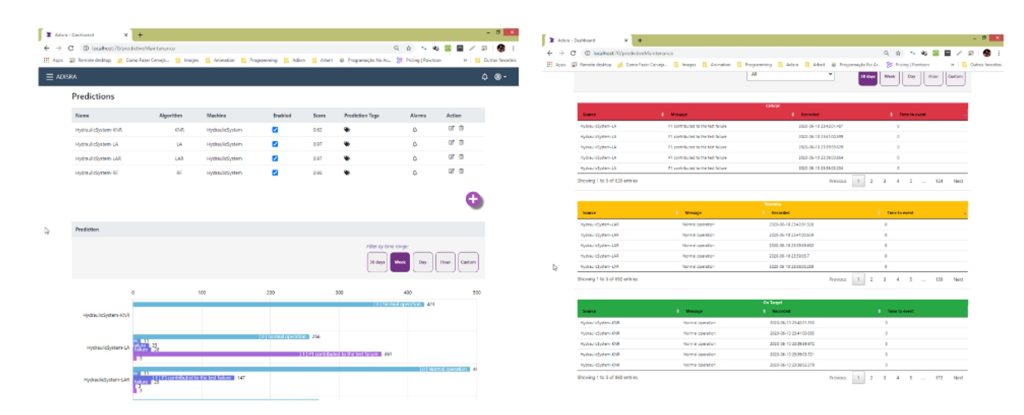

ADISRA KnowledgeView: Predictive Intelligence for Smarter Operations

ADISRA KnowledgeView is a next-generation, cloud-based predictive analytics platform designed to help manufacturers move from reactive maintenance to proactive, data-driven decision-making. Working independently or seamlessly alongside ADISRA SmartView and InsightView, KnowledgeView integrates historical data, machine learning models, and rule-based logic to detect anomalies, predict equipment failures, and recommend timely interventions.

Unlike routine or time-based preventive maintenance, predictive maintenance focuses on the actual condition of equipment, minimizing unnecessary service, reducing costs, and extending asset lifespan. With KnowledgeView, users gain the ability to forecast failures before they happen, reduce unplanned downtime, and improve overall equipment effectiveness (OEE) by directly addressing the Six Big Losses.

A New Era of Predictive Maintenance

KnowledgeView uses both supervised and unsupervised learning algorithms depending on the use case, allowing it to adapt to a wide variety of industrial challenges. From anomaly detection to trend analysis, the platform continuously monitors equipment behavior and flags performance deviations in real time, empowering users to act before a critical failure occurs.

Key Capabilities Include:

– Predictive Maintenance: Anticipate failures before they happen using real-time and historical sensor data

– Anomaly Detection: Identify unusual patterns or deviations that indicate early signs of failure

– Rule-Based Automation: Blend AI with expert-defined logic for accurate diagnostics and intelligent recommendations

– Cloud-Based Access: Securely view insights and alerts from anywhere, on any device

– Enterprise Scalability: Apply predictive models across machines, plants, and global sites

With ADISRA KnowledgeView, manufacturers gain a strategic advantage, moving beyond monitoring to foresight and resilience. By proactively addressing issues before they escalate, companies can reduce costs, extend asset life, and improve productivity across the board.

Interested in seeing KnowledgeView in action?

Request a temporary account to explore our predictive model for hydraulic systems here.

Conclusion

AI is rapidly becoming a cornerstone of OEE optimization in discrete manufacturing. By addressing the Six Major Losses head-on—with predictive insights, real-time monitoring, and automated improvements, AI is transforming factories into more innovative, more efficient, and more resilient operations. With platforms like ADISRA SmartView, InsightView, and KnowledgeView, manufacturers can embrace this AI-driven future to achieve higher efficiency, quality, and competitiveness.

Want a private webinar on any of these products? Request the webinar here.

Have questions or feedback? We are here to help! Feel free to contact us at info@adisra.com; we would love to hear from you.

Join Us for a Live Webinar!

Join us on July 24th at 9:30 AM CDT for an exclusive webinar highlighting the latest features and enhancements in ADISRA SmartView V4.1.3. Discover how these upgrades can help you build automation solutions that are faster, smarter, and more connected than ever before.

Register here to secure your spot.

At the end of the session, we will host a live Q&A, providing you with the opportunity to ask the ADISRA team any questions you may have about SmartView, including new features, best practices, or project-specific challenges. We are here to support your success.

ADISRA®, ADISRA’s logo, InsightView®, and KnowledgeView® are registered trademarks of ADISRA, LLC.

Copyright

© 2025 ADISRA, LLC. All Rights Reserved.